What are 3M PPA Polymer Processing Additives?

3M PPA processing aids have helped improve both quality and productivity. From extrusion technology: from bottles, plastic bags to construction materials like water pipes, electric cables, artificial grass,…

3M PPA processing aids are fluoropolymer-based additives designed to create a free-flowing process for plastics with efficient processing at low usage levels (100–1000 ppm). Therefore, a small amount can address common issues such as die build-up or sharkskin. This helps achieve a smoother surface, reduces waste, and increases productivity and consistent quality during processing.

3M PPA is widely used in processes such as blown and cast film, pipe and sheet extrusion, cable extrusion, and fiber production. 3M PPA works by creating a low-friction coating on the die surface. This allows the plastic to flow smoothly and freely through the die, resulting in smoother extruded surfaces and higher production speeds.

Let’s explore the benefits that 3M PPA processing aids can offer:

- Reduce or eliminate surface breakage or sharkskin

- Reduce die build-up

- Improve processing with high-viscosity polymers

- Reduce gel formation

- Decrease instability at interfaces in multilayer films

- Enhance color transition processes

- Improve surface gloss and smoothness

Choosing the right type of 3M PPA Processing Aid

Selecting the appropriate PPA for your application can make a significant difference. Even small differences in usage levels of just a few hundred parts per million (ppm) can greatly impact the production process. By simply providing a few details about your application, you can choose products that are most likely to be suitable for each specific use.

Hãy bấm vào đây để lựa chọn loại PPA cho bạn

Applications

Blown Film

3M PPA adds value to the blown film extrusion process by producing defect-free films while maximizing processing efficiency and minimizing production costs and risks.

Cast Film

Die build-up and gel formation can significantly impact productivity during the casting process. 3M PPA helps mitigate die build-up and other common issues.

Blow Molding

3M PPA allows customers to produce outstanding products with improved surface quality. It also increases productivity by reducing melt temperature, melt pressure, and cycle time.

Pipe Extrusion

Whether producing pipes from UHMW HDPE, LDPE, PP, or PVC for underfloor heating systems, irrigation, gas, and high-pressure water pipes, or other applications, we offer solutions to enhance gloss, reduce extrusion pressure, and eliminate surface defects without compromising product durability.

Electrical Cable

Eliminate die build-up, accelerate color transitions, and achieve a uniform cable surface with 3M PPA.

High-Load Compounding

Let 3M PPA bring vibrant colors to your world. Whether producing white compounds, carbon black, or colored masterbatches, 3M PPA can maximize your productivity by improving color dispersion, reducing color changeover time, and more.

iber and Monofilament Extrusion

When aiming to boost productivity in fiber extrusion with small die diameters, reliable solutions are essential to maintain high output. 3M PPA keeps everything running smoothly by reducing die build-up, die clogging, and fiber breakage.

Benefits of 3M PPA Polymer Processing Additives

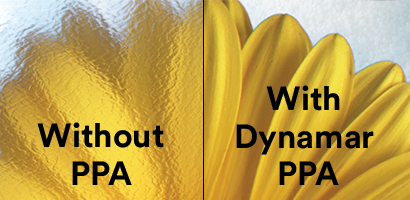

Preventing Sharkskin

Commonly known as “sharkskin,” melt fracture can be a significant issue during extrusion. This surface defect occurs when a thin layer of polymer/plastic adheres to the die wall instead of flowing smoothly through the die. It not only limits productivity but also reduces the smoothness and quality of the extruded plastic film surface.

While increasing the die gap can help reduce melt fracture by lowering shear forces, narrower die gaps are often preferred as they enhance biaxial film properties, stability, gloss, and optics. 3M PPA can reduce or eliminate sharkskin even at very low usage levels and under narrow die gap conditions.

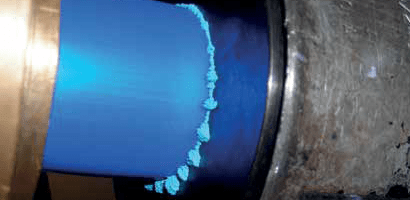

Prevent Die build up

During extrusion, waxy residues can accumulate on the die surface. This can disrupt productivity and cause surface irregularities in the film. The issue can become so severe that the extrusion process needs to be stopped for die cleaning.

3M PPA processing aids can help maintain smoother extrusion operations. These special additives have been proven to reduce die build-up in various polymers, including LDPE, PP, and many other plastics.

Phụ gia trợ gia công 3M PPA FX-5920A