Currently, there are many types of soundproofing materials available on the market, and each brand has different installation methods. When car owners are interested in soundproofing, what concerns do they typically have?

To address these issues, Hitta will clarify “SOME QUESTIONS CAR OWNERS HAVE WHEN LEARNING ABOUT SOUNDPROOFING” in the following article.

How many product lines does ASV car soundproofing offer?

Giải pháp cách âm xe hơi ASV bao gồm 2 dòng sản phẩm: cách âm và tiêu âm.

Cách Âm: Hiện tại, HITTA có 2 dòng cách âm là ASV-1102 và ASV-1102 PRO.

Tiêu âm: là vật liệu dạng Foam gồm có ASV-LF và ASV-TS

The ASV car soundproofing solution includes two product lines: soundproofing and sound absorption.

Soundproofing: Currently, HITTA offers two soundproofing lines: ASV-1102 and ASV-1102 PRO.

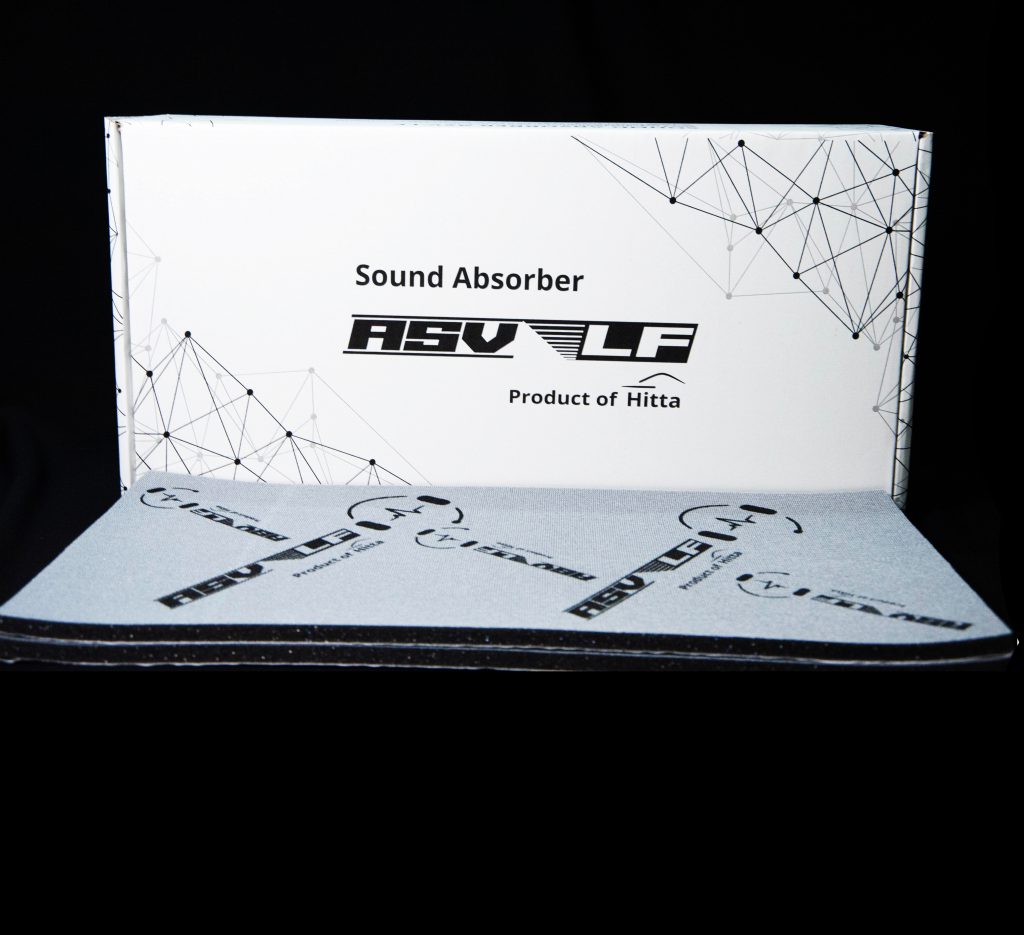

Sound absorption: These are foam materials and include ASV-LF and ASV-TS.

How many types of ASV car soundproofing are there?

ASV-1102 Line: This soundproofing line is made from butyl rubber and an aluminum layer. It effectively dampens vibrations and absorbs high-frequency sounds. The structure of this soundproofing material is carefully calculated to ensure high soundproofing performance while maintaining flexibility. This helps the soundproofing layer adhere well to metal and plastic surfaces inside the car, especially in difficult-to-stick corner areas. ASV-1102 is available in two thicknesses: 2mm for doors and roofs, and 2.5mm for floors, wheel wells, etc.

ASV-1102 PRO Line: This is an upgraded version of the ASV-1102. It features a thicker aluminum layer and modified butyl rubber, enhancing sound and vibration absorption in the car by up to 20%. ASV-1102 PRO comes in two thicknesses: 2.5mm for doors and roofs, and 3mm for floors. It is particularly suited for wheel wells.

How many types of ASV car sound absorption are there?

There are two different types of sound absorption materials:

- ASV-LF Sound Absorption: Made from polyurethane material with an open-cell foam structure, it has excellent low-frequency sound energy absorption capabilities, making it ideal for soundproofing doors, roofs, and interior cabin areas. ASV-LF also provides good thermal insulation properties for the vehicle.

- ASV-TS Sound Absorption: Made from PE material with a closed-cell foam structure, it effectively absorbs low-frequency sounds, offers good thermal insulation, and has excellent water resistance. ASV-TS is suitable for soundproofing floors, trunks, doors, roofs, etc.

Why are there both soundproofing and sound absorption materials for cars?

Current car soundproofing materials mainly dampen vibrations and reduce medium to high-frequency sounds. However, some medium to low-frequency sounds still penetrate the car and continue to reflect, causing echoes and booming noises. While car carpets and fabrics partially absorb these sounds, they are not entirely effective.

Therefore, in such cases, sound-absorbing materials (also known as acoustic materials) are the best choice. Among these, foam-based acoustic materials are the most effective at reducing echoes and booming noises, bringing clarity to your vehicle’s interior.

Mechanism of Car Sound Absorption

It’s quite simple—imagine a dish sponge. Instead of absorbing water, this sponge absorbs sound. While hard, flat surfaces (like metal panels in a car) reflect sound waves, these foam panels allow sound to enter and bounce around inside the foam’s cells until the energy is dissipated. Therefore, the thicker the foam and the higher the cell density, the more sound it absorbs.

With superior features:

- Effective sound absorption in the low-frequency range of 125-800Hz..

- High heat resistance up to 140 degrees Celsius.

- Fire resistance according to standards.

- Resistance to chemicals, oil, and grease.

- Long lifespan.

- Easy to install.

How much does noise reduce after soundproofing a car?

The amount of noise reduction depends on the car model. Typically, after ASV soundproofing, noise can be reduced by 5 to 7 dB, depending on the specific soundproofing package used.

How much noise reduction can be achieved after combining soundproofing and sound absorption?

Combining soundproofing with sound absorption can improve sound levels by 40 to 50 percent, depending on the car model.

Principles:

- Soundproofing significantly reduces noise inside the car, as measured in dB.

- Sound absorption reduces booming noises inside the car (this is not easily measured in dB).

Where to apply soundproofing in a car?

Effective Locations for Soundproofing a Car

The primary sources of noise in a running car include the trunk floor, doors, and wheel wells. Therefore, these are the critical areas to focus on for noise reduction and soundproofing.

Wheel Wells: This area generates noise and booming sounds due to the friction between the tires and the road surface, which directly impacts the interior. Addressing noise in this area is crucial, especially for low-ground-clearance cars like sedans. Proper soundproofing here can reduce noise by up to 50% compared to soundproofing the entire car.

Car Doors: Doors are directly exposed to external noise from the environment and surrounding vehicles. This is because the door panels are very thin. Soundproofing the doors significantly reduces noise from other vehicles and improves the quality of the car’s stereo system, making the sound richer and warmer.

Floor, Trunk, and Roof: These areas are directly affected by vibrations and road feedback, causing significant noise that is transmitted into the car’s cabin. Soundproofing these parts helps in reducing the overall noise level inside the car.

Should the car roof be soundproofed?

While the car roof doesn’t directly experience vibrations, wind and rain can create unpleasant sounds for passengers inside the vehicle. Additionally, the roof is directly exposed to sunlight, so soundproofing and thermal insulation for the roof are necessary.

Should wheel wells be soundproofed?

As mentioned above, wheel wells are areas where noise and booming sounds occur due to the friction between the tires and the road surface, making addressing noise in this area crucial. Especially for low-ground-clearance cars like sedans, soundproofing the wheel wells can reduce noise by up to 50% compared to soundproofing the entire car.

However, to ensure high adhesion, prevent peeling, and maintain soundproofing effectiveness during use, the following points should be noted:

- Soundproofing should be applied before undercoating or combined with an undercoating package to enhance soundproofing.

- If the wheel wells have been undercoated, the undercoating layer should be removed to enhance adhesion and soundproofing effectiveness.