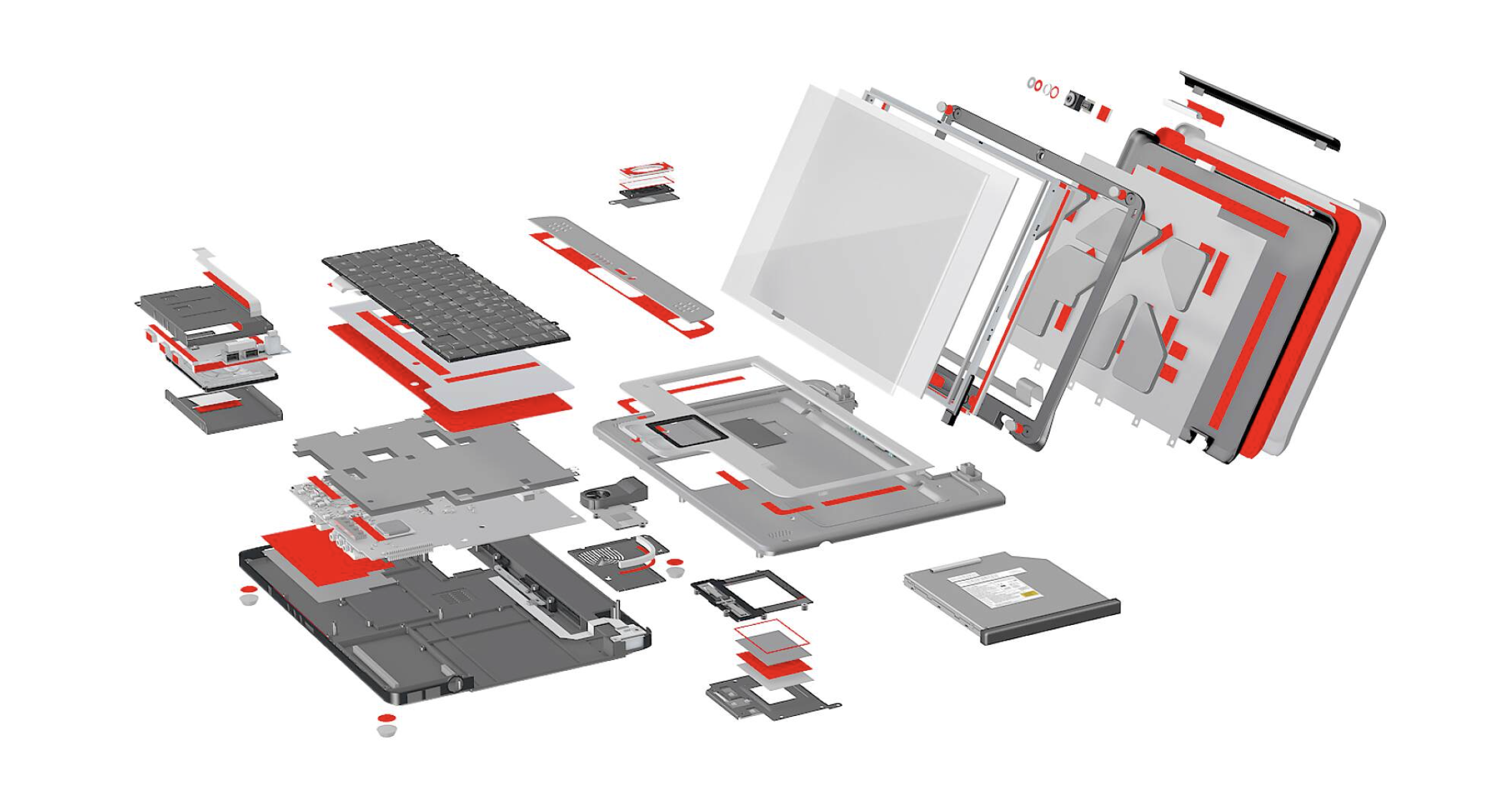

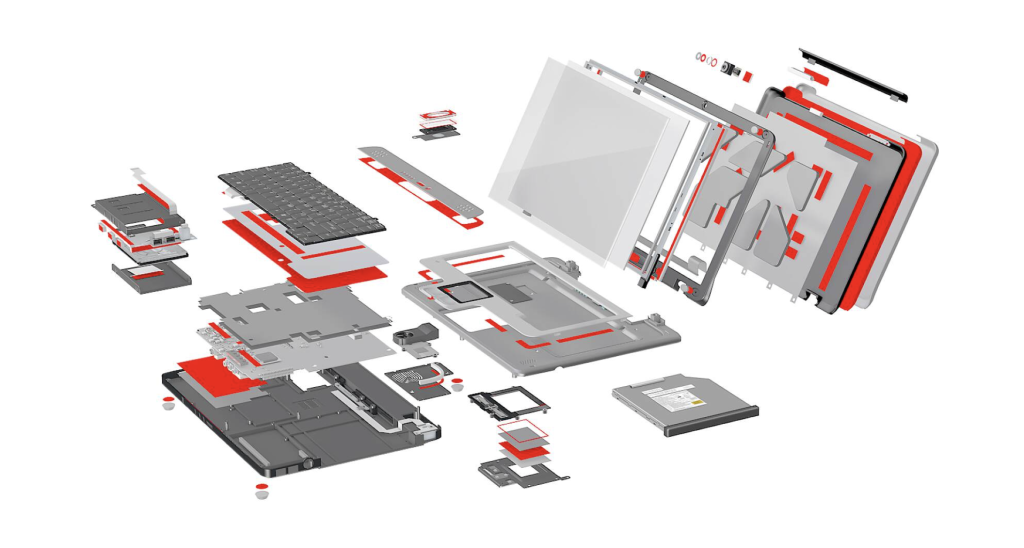

Adhesive tapes are a critical component in the laptop assembly process, providing solutions for bonding, insulation, and protection across various parts of the device.

These adhesive tape solutions are widely used due to their efficiency, ease of application, and versatility in handling different assembly requirements.

Types of Technical Tapes

Double-Sided Tapes: These are crucial for securing components like the LCD screen to the laptop frame. This type of tape offers a clean, efficient, durable bonding solution that is easy to apply. The general requirement for these tapes includes excellent adhesion and durability, essential for maintaining the structural integrity of the laptop over time.

Transfer Tapes: Often very thin, these tapes are used for bonding intricate components such as touchpads and keyboard elements. They provide high initial tack, which is vital for quick assembly processes, and can be used on various surfaces, including metals, plastics, and composites.

Foam Tapes: These tapes are used for components that require shock absorption and vibration dampening, such as hard drives and battery packs. They are particularly useful in reducing noise and minimizing vibrations and shocks.

Thermal & Electrical Management Requirements

Thermal Management: This is a crucial aspect of laptop design, as overheating can lead to hardware failure and reduced lifespan.

Thermally Conductive Tapes: These tapes are designed to transfer heat away from sensitive components like CPUs and GPUs. They are made from materials with high thermal conductivity, allowing them to dissipate heat effectively.

Electrically Insulating Tapes: Besides managing heat, it is important to prevent electrical interference and shorts. Electrically insulating tapes are used around sensitive electronic components to provide electrical isolation and protect against potential damage. These tapes are particularly useful in high-voltage areas and for components like the power supply and motherboard.

Specialized Applications

As laptops become more complex and compact, adhesive tapes have evolved to meet more specialized needs.

EMI/RFI Shielding Tapes: These tapes are designed to block electromagnetic interference (EMI) and radio frequency interference (RFI), which can disrupt the performance of electronic components. They are commonly used during the assembly of laptop enclosures and around sensitive components like antennas and wireless communication modules. This protection is crucial in maintaining signal integrity and device functionality in environments with high electronic noise.

Sealing Tapes: Sealing tapes are used to protect laptops from dust, moisture, and other environmental elements. These tapes are often applied during the assembly of laptop casings and around ports to ensure a tight seal, thereby safeguarding the internal components from exposure to potentially damaging external conditions.

Aesthetic and Finishing Tapes: For high-end laptops, aesthetic considerations are as important as functionality. Adhesive tapes are employed to attach branding elements, cover screws, and provide a clean finish. These tapes must offer strong adhesion while being removable without leaving residue, ensuring that the laptop’s appearance remains pristine. This is particularly important in consumer electronics, where visual appeal can significantly influence consumer choice.

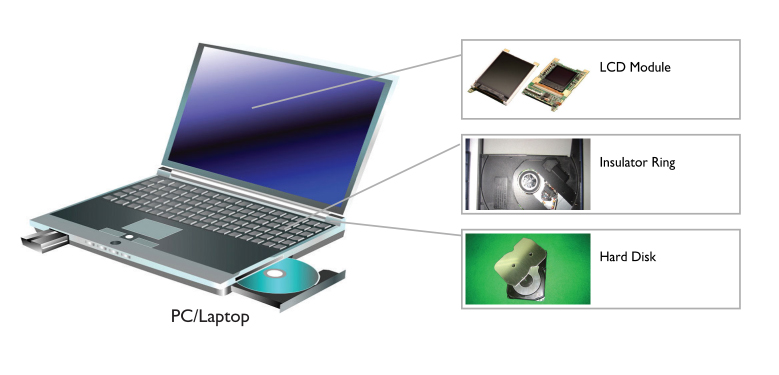

Technical Tapes in LCD Module Assembly

Screen Adhesive Tapes

The LCD module in a laptop is a crucial component that requires precise assembly to ensure a clear display and secure installation. Double-sided adhesive tapes are commonly used to bond the LCD panel to the frame, providing strong adhesion while maximizing space efficiency. These tapes are typically made from materials like acrylic, known for their excellent durability and bonding properties.

Optical Tapes for Light Management

Optical tapes are used to enhance the brightness and clarity of the screen. These tapes can be applied to the edges of the screen to manage light diffusion and reflection, ensuring even backlight distribution across the entire LCD panel, thereby improving the overall visual experience.

Thermal and Electrical Insulation

LCD modules generate heat, and managing this heat is crucial to maintaining the longevity and performance of the display. Technical tapes designed for thermal management, such as those made from silicone foam, are used to provide insulation. These tapes help dissipate heat away from the screen, preventing overheating and potential damage to nearby components.

Insulator Rings in Laptop Assembly

Purpose and Application

Insulator rings are used in laptops to prevent electrical short circuits by insulating various components. These rings are typically placed around sensitive electronic parts such as the CPU, GPU, and power circuits. They play a crucial role in maintaining the integrity of electrical insulation, which is vital for the safe operation of the device. By isolating these components, insulator rings help prevent unintended electrical contact that could damage the components or the entire system.

Materials Used in technical tape

The materials used for insulator rings include polyimide, silicone, and other high-dielectric strength materials. These materials are chosen for their excellent thermal stability and electrical insulation properties. For example, polyimide tapes are known for their ability to withstand high temperatures, making them ideal for use in areas close to heat-generating components like the CPU and GPU. Silicone tapes are also used for their flexibility and durability under thermal stress, providing reliable insulation in diverse environmental conditions.

Installation Techniques

The installation of insulator rings involves precise placement and securing, often using adhesive tapes designed to maintain adhesion under high temperatures. These tapes ensure that the rings stay in place and provide continuous insulation throughout the laptop’s operation cycle. Advanced tapes may also feature properties to mitigate thermal runaway, offering additional protection in high-performance laptops. These specialized tapes not only secure the insulator rings but also contribute to the overall thermal management system by reducing heat accumulation around critical components.

Technical Tapes in Hard Drive Assembly

Vibration and Shock Reduction

Hard disk drives (HDDs) are highly sensitive to vibrations and shocks, which can lead to data loss or hardware damage. To mitigate these risks, vibration-dampening tapes are used to secure the HDDs within their bays. These tapes are typically made from foam materials like polyurethane or silicone, which are known for their excellent shock-absorbing properties. The use of these materials helps in cushioning the HDD, thereby reducing the risk of damage due to physical impacts or drops.

Thermal Management

Like LCD modules, hard drives also generate heat during operation, which needs to be managed to prevent overheating. Thermal interface materials (TIMs) in tape form are used to transfer heat away from the hard drive and dissipate it efficiently. These thermal tapes are often placed between the HDD and the metal chassis of the laptop, which acts as a heat sink. This setup helps in maintaining optimal operating temperatures for the hard drive, thereby enhancing its longevity and reliability.

Electrical Insulation

In addition to physical protection, hard drives also require electrical insulation to prevent short circuits. Technical tapes with insulating properties are applied in areas where the hard drive comes into close contact with the laptop’s internal components. These tapes ensure that electrical currents are confined to the intended pathways, protecting both the hard drive and the motherboard from potential electrical shorts. This is especially crucial in laptops where space constraints can lead to components being positioned in close proximity, increasing the risk of accidental electrical contact. The insulating tapes used are typically made from materials like polyimide or silicone, which offer excellent dielectric properties and thermal stability, further ensuring the safety and reliability of the device.

Special Considerations for SSDs

Differences from HDDs

Solid State Drives (SSDs) differ from Hard Disk Drives (HDDs) in that they have no moving parts. This design inherently makes SSDs more resistant to mechanical failures caused by vibrations or shocks. However, they still require some level of vibration protection, though to a lesser extent compared to HDDs. Additionally, SSDs benefit from thermal management tapes to dissipate heat effectively, ensuring stable operation under various workloads.

Adhesion and Insulation

The smaller form factor of SSDs allows for more compact tape solutions. The adhesive tapes used in SSD assembly are typically thinner and provide both strong adhesion and electrical insulation. This ensures that SSDs remain securely fixed within the laptop chassis, even under extensive use and during transport. These tapes also help in isolating electrical currents, preventing potential short circuits and protecting the SSD and other internal components.

Contact Information

For specialized adhesive and tape solutions in both industrial and commercial sectors, Hitta offers expert consultation to help identify the most effective and cost-efficient solutions. Contact them for high-performance adhesive solutions tailored to your specific needs.

- ☎️ Hotline: 0565.336.879

- ✉️ Email: hittajsc@hitta.vn