Technology is changing the way we do things, and in industrial manufacturing and assembly, mechanical screws and bolts are gradually being replaced by PSA products (such as structural tapes). Today, let’s explore the technology behind this transformation together with Hitta.

What is PSA?

PSA stands for Pressure-Sensitive Adhesive, meaning adhesive that sticks upon application of pressure. As per its definition, PSA adheres without the need for solvents, heat, or chemical reactions, and it possesses the following characteristics:

- Adhesive that sticks without the need for solvents, heat, or chemical reactions.

- Maintains permanent adhesion at room temperature and can adhere to various surfaces with light pressure (such as the force of pressing with a finger), while maintaining its state after bonding (remaining either liquid or solid).

- Adhesive strength depends on the applied force, surface structure, surface energy, cleanliness of the surface, etc.

PSA are primarily used in the manufacturing of: single-sided tapes, double-sided tapes, structural tapes, labels, decals, films, etc.

The advantages of using adhesive tapes utilizing PSA technology include:

- Quick adhesion capability.

- Uniform thickness of the bond.

- Odorless, hence no need for ventilation systems.

- No drying or curing process required.

- No chemical reaction during bonding.

- Elasticity of the bond.

- Vibration reduction capability.

- Even distribution of impact force on the bond.

- Ability to prevent water, air, and dust.

- Bonding of different material surfaces.

- Insulation capability.

- Various tools available for automation of the bonding process.

Plus:

- Bonding of different material surfaces.

- Bonding of materials with low surface energy.

- Prevention of water, air, and dust.

- Reduction in vibration and noise.

- Brand recognition.

- Reduction in the weight of the bond.

- No surface damage during bonding.

Common Types of PSA Bases

Rubber: Adhesive based on natural or synthetic rubber, formulated with tackifiers, oils, and antioxidants. Rubber-based adhesives are the most cost-effective and provide quick adhesion. Rubber adhesives are not recommended for high-temperature applications.

Acrylic: Adhesive formulated from acrylic polymers, typically with longer durability and better resistance to solvents and weather conditions. Acrylic adhesives often develop a stronger bond compared to traditional rubber-based adhesives and can withstand higher temperatures (up to 260°C).

Silicone: Formulated with silicone polymers and is the only adhesive that bonds well with silicone substrates. Silicone adhesives are relatively expensive and have very low initial tack, but they can withstand higher temperatures (up to 300°C) compared to both rubber and acrylic adhesives.

Comparison Table of Characteristics:

Sure, here is the datatable translated into English:

| Property | Rubber | Acrylic |

|---|---|---|

| Cost | Lowest | Medium/High |

| Initial tack | Medium/High | Medium/Low |

| Heat resistance | Low | High |

| Adhesion | Medium/High | Medium/High |

| Initial bonding time | Medium/High | Medium/Low |

| Solvent resistance | Poor | Good |

| UV resistance | Poor | Very good |

| Ability to bond low-energy surfaces | Very good | Medium/Good |

| Ability to bond high-energy surfaces | Very good | Very good |

To qualify as PSA adhesive, a tape must have three properties:

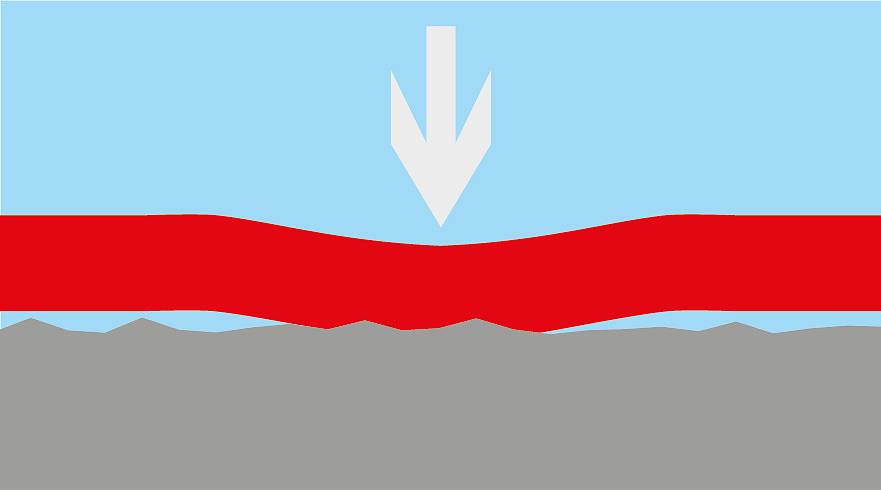

- Adhesion: Refers to the strength of the adhesive or the material adhering to the substrate or surface the tape is applied to.

- Cohesion: Used to indicate strength.

- Tack: Refers to the time it takes for the adhesive to adhere to a substrate or specific surface. An extremely tacky tape will adhere immediately with minimal pressure. Less tacky tape will require more pressure to adhere.

Why Use PSA?

PSA adhesive provides fast, efficient results and is becoming increasingly popular for several reasons:

- Material Advantages: PSA adhesive products are thin and lightweight, making them easy to use.

- Quick Bonding: Because PSA adhesive requires only pressure to bond, it quickly bonds different materials together with ease. You don’t have to worry about material compatibility. So, when you use PSA adhesive, you can assemble a project quickly without waiting for adhesion or solvent to perform the job. Simply press the tape, and it will adhere.

- Noise Reduction: When you use products with PSA adhesive, you can reduce noise caused by vibrations. The tape will not rattle like traditional ties but will also absorb noise.

- Aesthetic Appeal: PSA adhesive products have a more pleasing appearance. PSA adhesive also reduces the need for repainting surfaces, eliminates visible mechanical screws or ties. You no longer see screws or ties but instead have a smooth finish layer. Additionally, PSA tape creates uniform thickness, can be used to fill gaps, and creates products with higher aesthetic value.

What is PSA Used For?

As mentioned, PSA is primarily used in the production of various types of tapes such as single-sided tape, double-sided tape, reinforced tape, labels, decals, film, etc. Therefore, the capabilities and applications of PSA adhesive are reflected in the products constructed with it.

If you pay attention, you will notice the ubiquitous presence of PSA adhesive all around you. Tape for sealing boxes or packaging, double-sided tape, single-sided tape, sports tape—all are different variations of PSA adhesive.

Not only used for bonding, PSA can also be employed for shielding EMI/RFI filters, managing heat, obscuring areas, surface protection, vibration damping, sound attenuation, sealing, padding, and many other solutions.

Requiring just a bit of pressure to activate, you can find PSA products in all industries, even in healthcare with sports tape and wound care solutions.

Some industrial applications of PSA adhesive with reinforced tape include:

- Giải pháp băng keo cường lực

- Tại sao nên sử dụng băng keo cường lực

- Băng keo cường lực cho thang máy

Types of Adhesive Used for PSA?

As outlined in the section on Types of PSA Adhesive Bases, the adhesives used for PSA include Rubber, Acrylic, and Silicone. We’ll delve into more detail in this section.

Rubber

Rubber is the least expensive with the fastest tack. Rubber adhesives can be either natural or synthetic rubber. Companies formulate these adhesives with resin, oil, and antioxidants.

Rubber adhesives perform best indoors with less harsh environments compared to outdoors. They bond well to low-energy surfaces. You can find rubber adhesive on masking tape, carton sealing tape, etc.

Rubber’s inherent tackiness is not noticeable, so engineers add resin to create the necessary adhesive properties.

Natural rubber has larger molecular weight than synthetic rubber and adheres well to low-energy surfaces. However, it can be cleanly removed, but its downside is its poor thermal performance and short lifespan.

Synthetic rubber, often referred to by engineers as “hot melt” adhesive, is a thermoplastic resin with a lighter weight and shorter polymer chain than natural rubber. Thus, engineers customize it more, making it adhere better to a wider range of surfaces.

Acrylic:

Acrylic adhesives maintain their bond better over time. They tend to resist degradation from solvents and environmental factors. Moreover, they can withstand higher temperatures than rubber adhesives and develop a stronger bond.

People tend to use acrylic adhesives both indoors and outdoors due to their longer lifespan compared to other adhesives.

In essence, acrylic adhesive is very tacky, but engineers often make them even tackier. Acrylic adhesive polymers are very flexible. Developers can adjust them during manufacturing to make the adhesive work better.

Acrylic solvent adhesives come from bead particles dissolved in solvents. This adhesive does not bond well to low-energy plastic surfaces but bonds better than rubber.

Emulsion acrylics originate from spherical particles surrounded by a surfactant in a water-based carrier. Emulsion acrylics are lower cost and more environmentally friendly than solvent acrylic adhesives. Their water-based nature makes them less moisture-resistant, so many prefer solvent acrylics.

Silicone

Both rubber and acrylic do not bond with silicone like silicone adhesive does.

Silicone adhesive has the highest cost among adhesives. They can withstand very high temperatures and thus handle harsher environments better than other adhesives.

Many believe silicone adhesives have low initial tack as they do not bond well initially. However, time has proven otherwise.

Typically, people use silicone adhesive tapes for critical applications where the tape contacts extreme temperatures and skin contact. The best thing to adhere to silicone adhesive is silicone, so users often use silicone adhesive in these cases.

You can find silicone adhesives in Teflon tape, PCB film tape, etc.

When choosing the best PSA product for your specific job, consider the following criteria:

- What surface are you applying the adhesive to?

- What are the conditions the PSA will be exposed to? Is it high temperature, moist environments, or windy conditions?

- Why are you using this PSA? What is your purpose?

- How do you plan to apply the PSA?

- Are you using the PSA as a long-term or temporary solution for a problem?

Base your decision on the answers to these questions. Look for a tape that can withstand the conditions and perform well on your surfaces.

If you still feel confused, feel free to contact Hitta for the best expert advice.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn