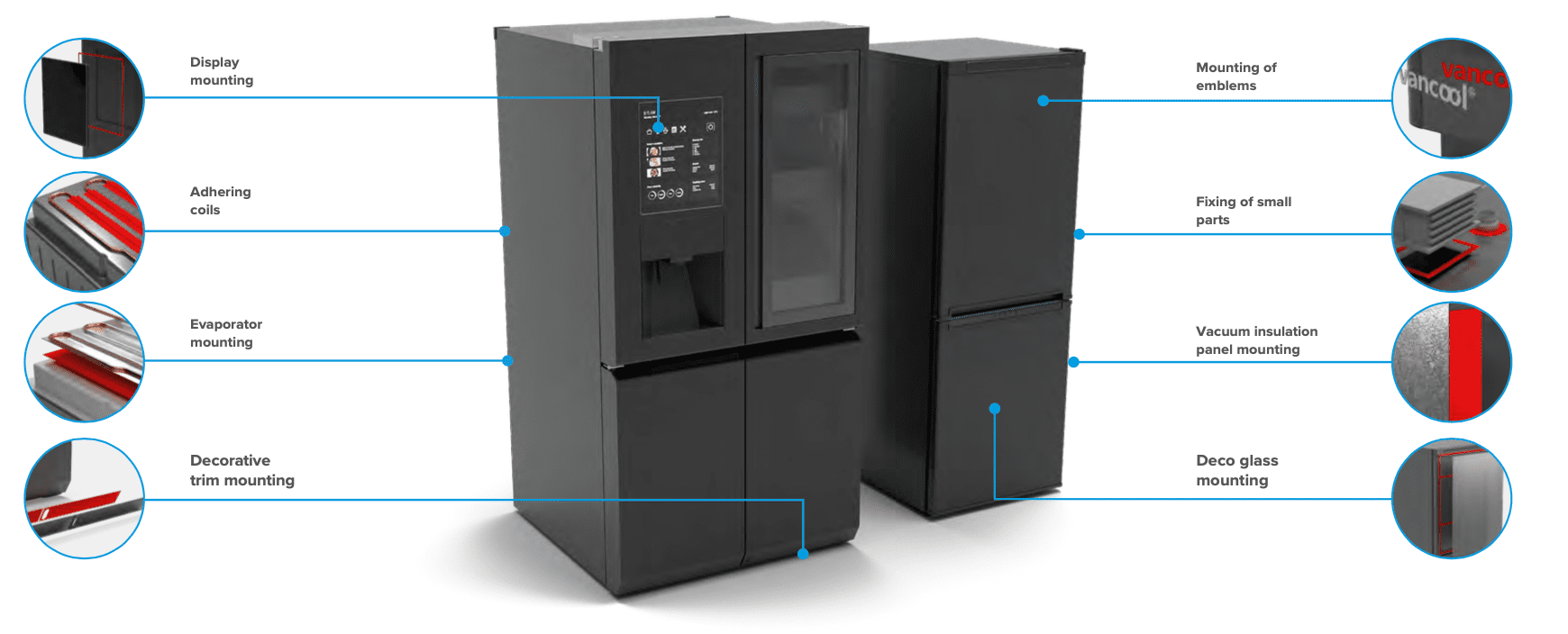

Mounting and fixation

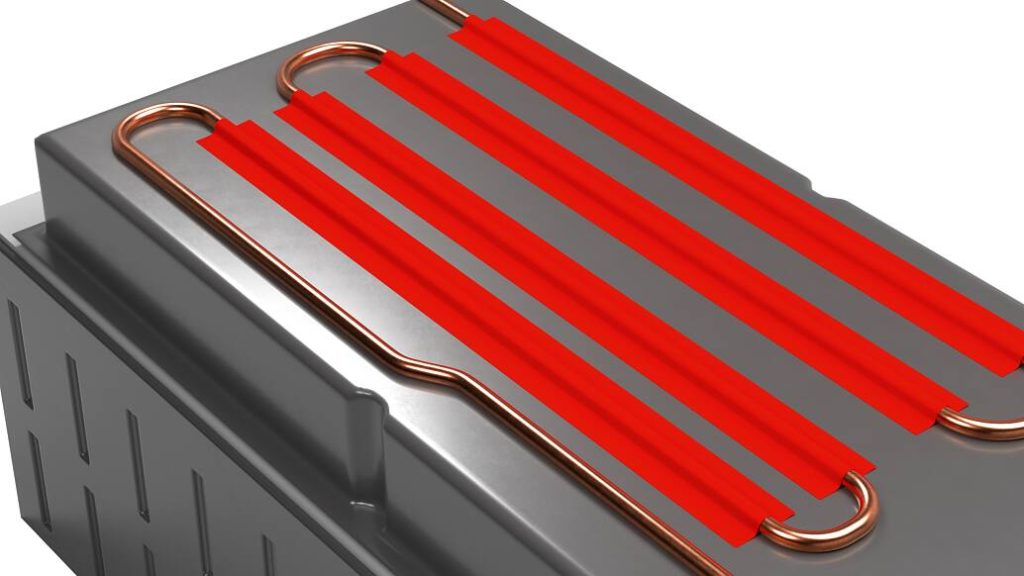

Cooling Coil Adhesion

The cooling coils of refrigerators and freezers are firmly attached to the polystyrene body to allow for the highest possible heat transfer rate. This process is even more efficient when using aluminum foil tape.

The tapes used for this application feature a flexible backing and high bond strength on both metal and polystyrene, and are also easy to remove. This type of tape may or may not have a liner.

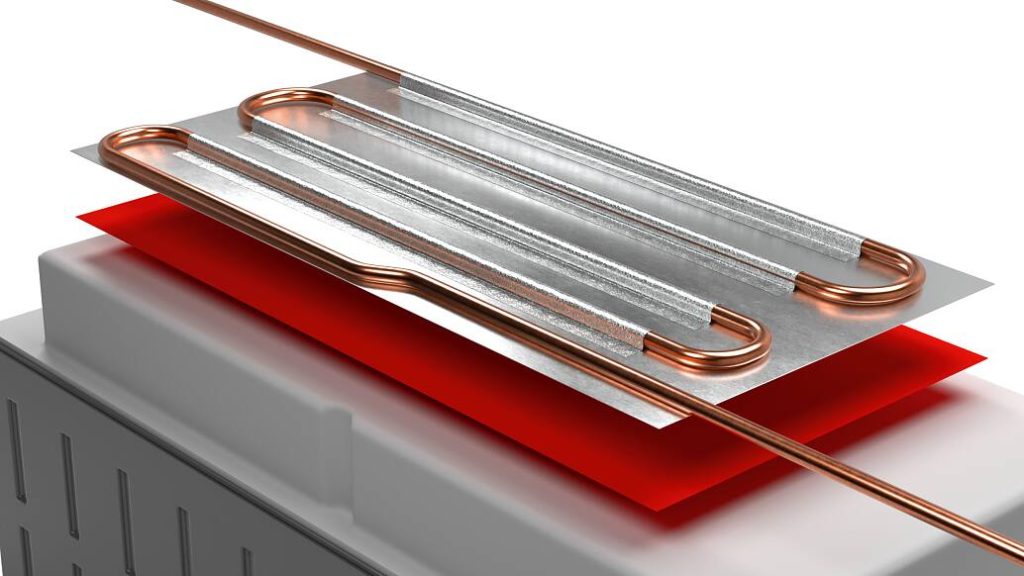

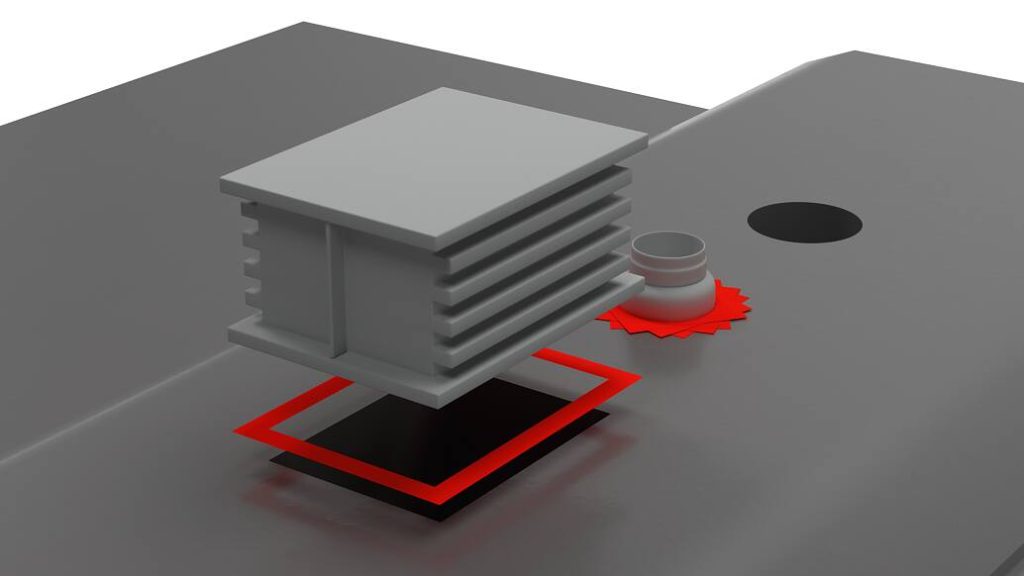

Evaporator Mounting

Directly bond to the entire surface (100%) of the polystyrene body’s back to prevent the polystyrene foam from shifting after injection.

After spraying polyurethane (PU) foam, there is a risk that the evaporator unit may shift beneath and deviate from its correct position. Bonding the entire area of the evaporator unit directly to the back of the polystyrene (PS) body will prevent this.

The tape used must have high adhesive strength and be adequately sticky to both metal and polystyrene. The tape’s liner should be easy to remove, even when opting for tape of larger dimensions.

Decorative trims

When mounting plastic or metal components for decoration on the front door, tape offers numerous benefits, notably providing a clean and tidy manufacturing process.

Using double-sided tape to attach plastic or metal decorative details is the optimal solution.

This application is particularly suitable for decorative elements designed to cover gaps in integrated devices.

Furthermore, the high bond strength of the tape helps to secure the decorative components and foam layer, reducing impacts and eliminating rattling noises. The tape for this application is also designed to be temperature resistant, thereby enhancing durability and weather resistance.

Mounting logo

With double-sided tape, logos can be attached without the need for drilling holes in metal or plastic surfaces—ideal for prefabricated assembly.

The types of tape used must be durable, have high adhesion to plastic, and be easy to die-cut

Mounting of displays

Attaching/mounting display screens with double-sided tape is efficient and clean. This neatness, along with precision, is a critical requirement when installing screens for high-end refrigerators.

The tape required for this application must have high adhesion to plastic and a flexible backing. Additionally, the tape should be easy to die-cut.

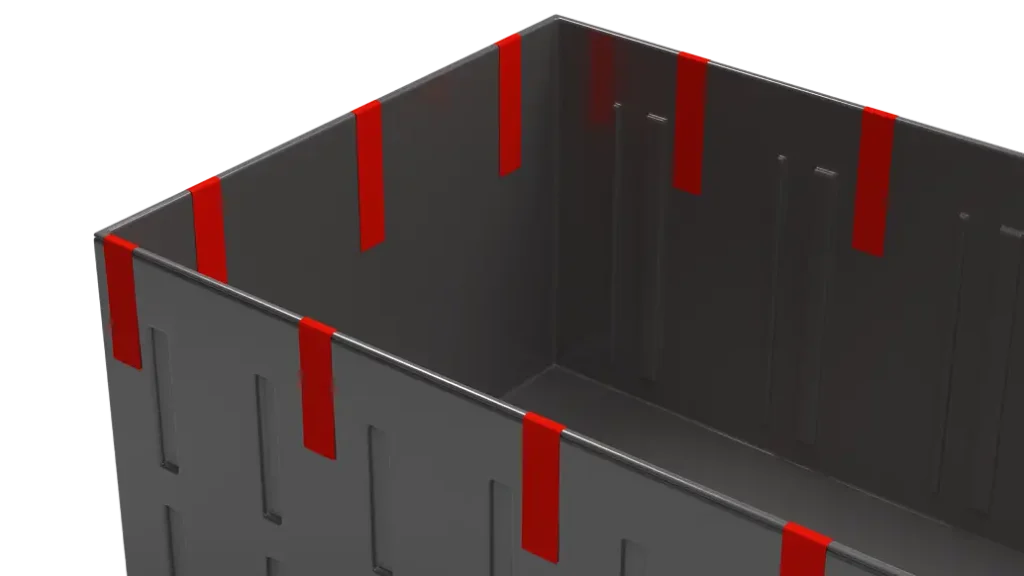

Fixing small parts/details

Many small components made of plastic or metal need to be attached to the polystyrene body. Handling and positioning these parts become easier if they are equipped with double-sided tape.

Assembling these pre-taped components can speed up and enhance the efficiency of the process.

The tape required must adhere strongly to polystyrene, have a suitable backing to stick to uneven surfaces, and prevent polyurethane (PU) foam from being squeezed out. It should also be capable of being die-cut.

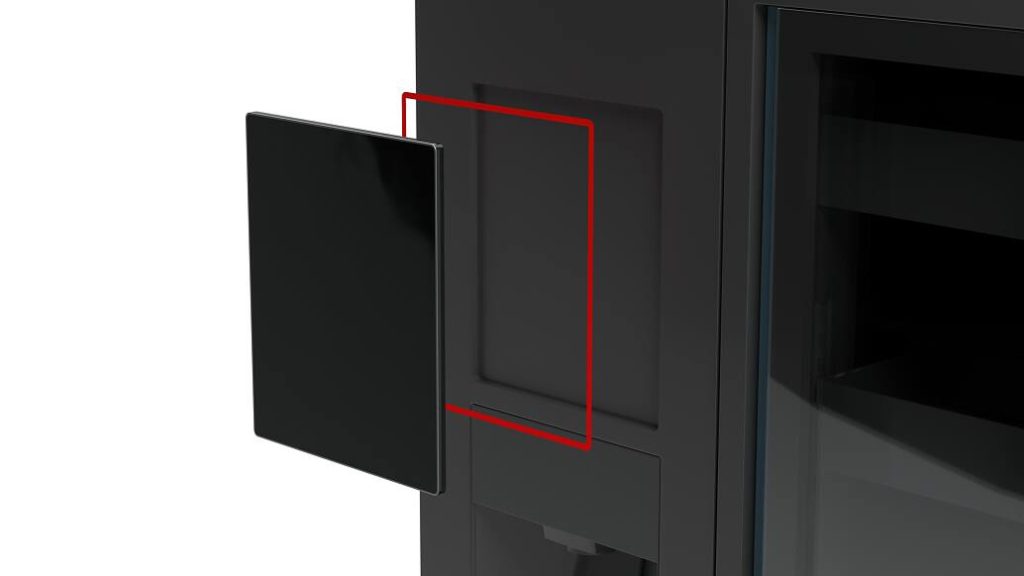

Deco glass mounting

The method of attaching decorative glass panels efficiently and elegantly, without the need for screws or maintenance time, is considered superior to adhesive solutions (which risk dripping) by using double-sided tape.

The tape used is typically deep black to blend seamlessly with the resilient acrylic core. The tape must have good shock-absorbing properties and high adhesion to glass and aluminum.

Transport, Protection

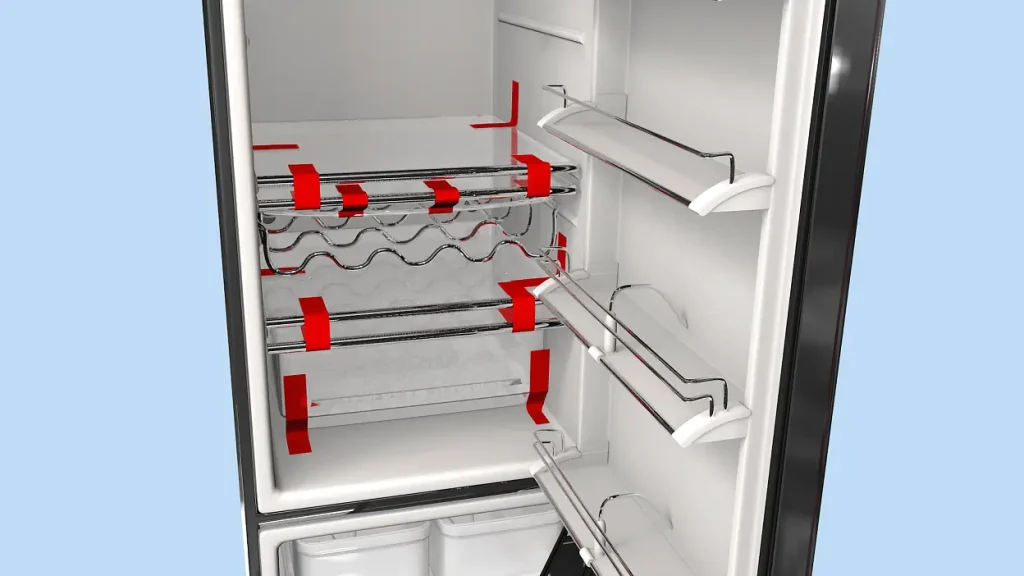

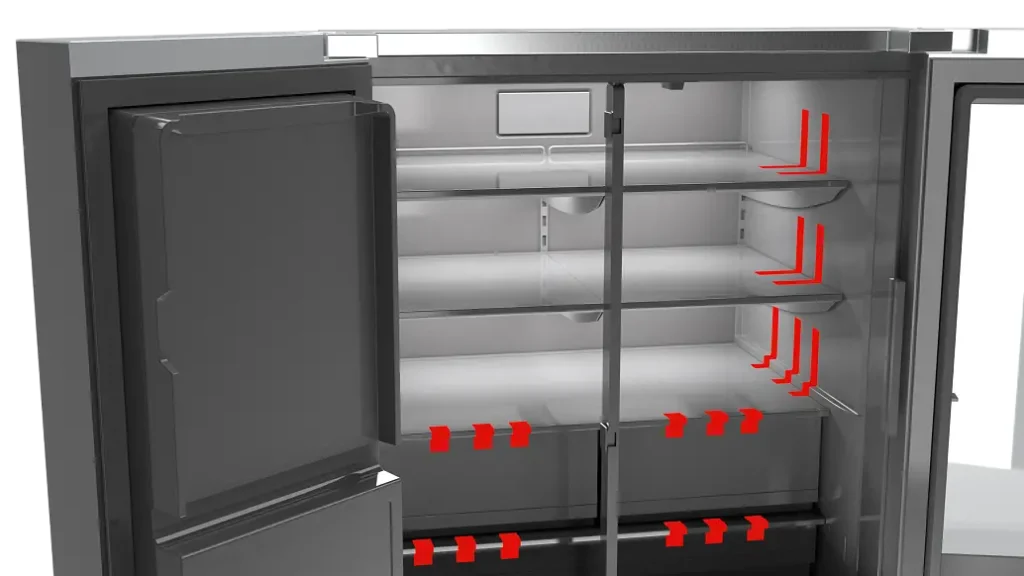

Securing shelves, bins & doors for transportation

Using tape for securing during transportation prevents damage to glass shelves and other small components.

Shelves, individual containers, and other small parts can be securely held in place during transport using tape.

The tape must be sturdy and shock-absorbing, removable without leaving residue, and possess high tensile strength to prevent shaking and tearing.

Surface Protection

Film and plastic tapes are used to cover metal, glass, stainless steel, plastic, and other surfaces during assembly, transportation, or installation.

During assembly, transportation, or installation, important glass, plastic, or painted metal parts can be scratched or become dirty. Removable surface protection tapes can be used for temporary or permanent surface protection.

The tape used must have adequate adhesion and be resistant to aging while leaving no residue upon removal.

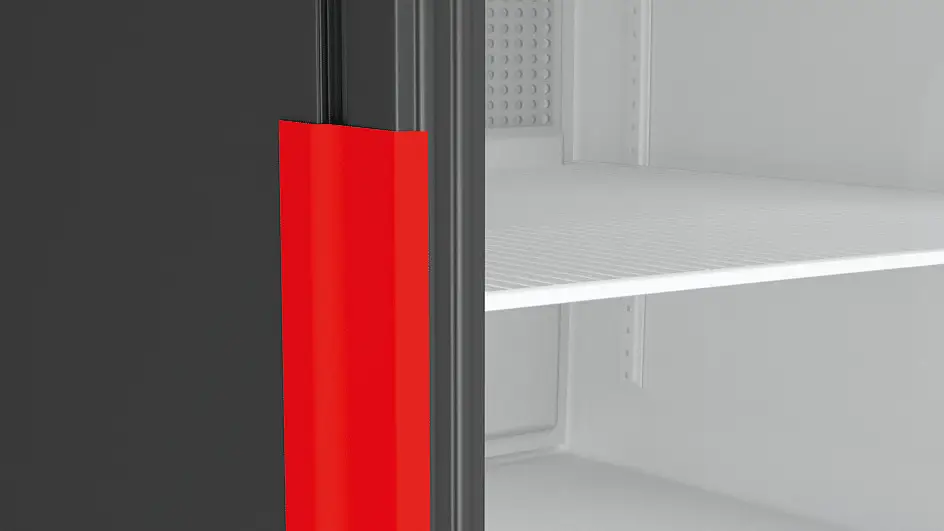

Protecting/securing doors

Tape will bear a part of the load so that strong impacts do not affect the door hinges, thereby preventing damage.

During the transportation of doors, strong impacts can damage parts of the door, especially the hinges. By using specialized adhesive tape that can bear part of the load, damage from impacts can be avoided.

The tape used must be very durable with a backing capable of withstanding high forces and should leave no residue upon removal.

Air permeability

Venting tape covers holes to prevent the PU foam from squeezing out during injection while still allowing air flow.

Venting tape can be used to cover all holes on an appliance during injection in order to prevent PU foam from squeezing out. Venting tape covers holes sufficiently while still allowing air flow. This ensures that an excess of pressure is avoided.

The tape used should have a backing that allows sufficient air flow. Furthermore, it should be hand tearable and available as die cuts.

Gap covering

Covering all gaps and joints helps prevent PU foam from being expelled during spraying. Fabric tape is most suitable for the contours of small corners.

During the foam spraying process, there is a risk that PU foam might be forced out of small gaps and joints. To prevent this, tape should be used with PU foam to cover all gaps and joints. In small corners and joints, the best solution is to use fabric tape, as it easily conforms to shapes.

The tape used must have high adhesive capability. The backing should bond with the PU foam and be easy to remove, allowing for hand tearing.

Reinforcement

Securing the form where two parts (e.g., the polystyrene body and the metal casing) are joined will prevent PU foam damage during spraying. This avoids the risk of damage during the form filling process.

The tape used for this purpose must have very high tensile strength and resistance to cutting and tearing, and it should be removable without leaving any residue.

Hole covering

Hole covering and gaps in the polystyrene body or door helps prevent PU foam from being expelled during spraying.

During the spraying process, PU foam can escape from these voids and holes. To prevent this, all holes and gaps in the polystyrene body and door must be sealed. A suitable tape, compatible with PU foam, should be used to effectively prevent the foam from being expelled.

The tape used must be tearable by hand and have adhesive properties to ensure a firm bond.

Contact us

Hitta specializes in providing various adhesives and tapes for both industrial and commercial sectors. Contact us for consultations on the most effective solutions at the lowest cost:

- ☎️ Hotline: 0565.336.879

- ✉️ Email: hittajsc@hitta.vn