What is Transfer tape?

Transfer tape consists of an adhesive layer without a carrier, only a release liner. The adhesive layer is a PSA (Pressure Sensitive Adhesive), either solvent-based acrylic or hot melt rubber-based with various coatings.

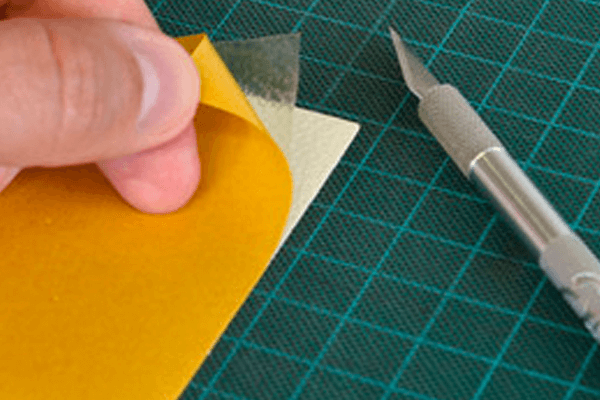

Transfer tape allows users to accurately see the position where labels need to be placed on the surface.

Type of transfer tapes

The three most common types of transfer tape are: clear, paper, and grid. To facilitate comparison, Hitta provides an example application in design with vinyl:

Clear transfer tape is ideal for achieving a refined and seamless appearance for vinyl plastic designs. Its transparency facilitates easy alignment of vinyl designs with the desired surface, and its strong adhesive ensures that the vinyl design remains secure. Clear transfer tape is also highly suitable for use on uneven surfaces, as its flexibility allows the tape to adhere firmly without wrinkling.

On the other hand, paper transfer tape is ideal for those who want more control over the application process. The paper backing layer aids in handling and positioning the vinyl design more easily and can also serve as a guide when cutting vinyl designs to size. One drawback of paper transfer tape is that the paper backing layer may sometimes leave residue after transferring the vinyl design.

Grid transfer tape, as the name suggests, features a grid pattern printed on the back of the paper. This helps facilitate measuring and cutting vinyl designs to size more easily, while also providing visual guides for aligning the vinyl design with the desired surface. Grid transfer tape is a popular choice among professionals and individuals working on larger vinyl projects as it helps ensure accuracy and consistency.

How transfer tape works?

Transfer tape is commonly used in an application process called lamination. This term refers to the bonding of two or more layers together using pressure and heat.

The transfer tape is placed between the base layer and the outer layer, and then the entire assembly is passed through a set of rollers. This process allows the adhesive to bond with both surfaces, creating a strong and durable bond that can withstand various conditions.

There are many types of transfer tape available on the market, each with its own features and benefits. Ensure you select a transfer tape that is compatible with the substrate you are using. Additionally, consider the adhesive’s suitability for the intended conditions of use. For example, if you are using transfer tape for outdoor applications, choose a type of adhesive that can withstand UV rays and harsh temperatures.

Advantages and Disadvantages of transfer tape

ADVANTAGES:

- Flexible and adaptable to irregular shapes.

- Versatile and aesthetically pleasing design.

- Very thin for layering and stacking applications.

- No limitations on the temperature resistance of the carrier layer.

- Suitable for requirements of clarity and transparency.

- Replaces mechanical screws.

- Converters can combine transfer tape with a carrier to create custom double-sided tape.

- No limitations on the temperature resistance of the carrier layer.

DISADVANTAGES:

- Lacks reinforcing capability.

- Not easily able to bond two different materials.

- Limited load-bearing capacity.

- Thinness requires higher installation skill level.

The value that transfer tape brings includes:

- Convenience: can be applied quickly and easily.

- Precision: transfer tape can be die-cut to meet specific needs.

- Strong bonding: creates a robust bond between surfaces (substrates).

- Flexibility: transfer tape can be used for various applications.

Applications of transfer tape

When it comes to transfer tape, the first thing that comes to mind is its flexibility and thinness (some types are only 0.05 mm thick).

Transfer tape is suitable for elastic materials, printed circuit boards, thin plastics, and many other materials, even irregular shapes and sizes. Additionally, due to its thinness, transfer tape is the perfect choice for products requiring aesthetic appeal.

- Attaching nameplates and signage.

- Bonding different materials.

- Creating three-dimensional objects.

- Die-cutting.

- Laminating.

- Embossing.

- Foam mounting.

- Padding/Gasketing.

- Labeling.

- Packaging.

- Printing.

- Prototyping.

- Making signs.

Industries where transfer tape is applied include:

- Automotive.

- Construction.

- Electronics.

- Medical.

- Packaging.

- Printing.

- Telecommunications.

Each industry has specific requirements for the type of transfer tape used.

For example, the automotive industry requires transfer tape that can withstand high temperatures and vibrations.

The construction industry often uses transfer tape for temporary applications, such as holding pipes together during installation.

In the electronics industry, conductive transfer tape is used to create electrical connections between components.

In the medical field, sterile transfer tape is used in various applications, such as securing dressings in place.

Bounding

The most common use of transfer tape is as a type of tape to hold two materials together. Some examples include gasketing when using foam and an indifferent surface such as foil, heat shielding material, or high or low surface energy plastic.

Laminating

Most tapes used in laminating applications are typically transfer tapes. These are the most suitable type of tape in the market and bond well with common materials. Transfer tapes are used as laminating tapes on signs, graphics, or most surfaces that require compatibility and flexibility in application.

Purchase transfer tapes

Bow Tape’s transfer tape consists only of the adhesive layer without a carrier, providing optimal bonding performance. Bow Tape’s transfer tape is the best choice for laminating applications on foam & plastic.

Advantages:

- Double-sided adhesive without carrier layer.

- High temperature resistance & excellent bonding.

- Excellent performance in die-cutting applications.

- Ideal for applications on PP, PE plastics & other difficult-to-bond surfaces.

Please contact Hitta to purchase transfer tape & receive free consultation!

- ☎️ Hotline: 0565 33 68 79

- ✉️ Email: hittajsc@hitta.vn