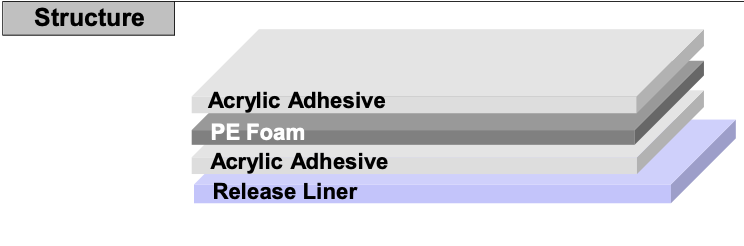

PE foam tape or Polyethylene foam tape is a composite adhesive consisting of a high rubber or Acrylic adhesive compound with a closed-cell foam suitable. Thanks to the high rubber adhesive compound, PE foam tape provides excellent initial adhesion to various surfaces.

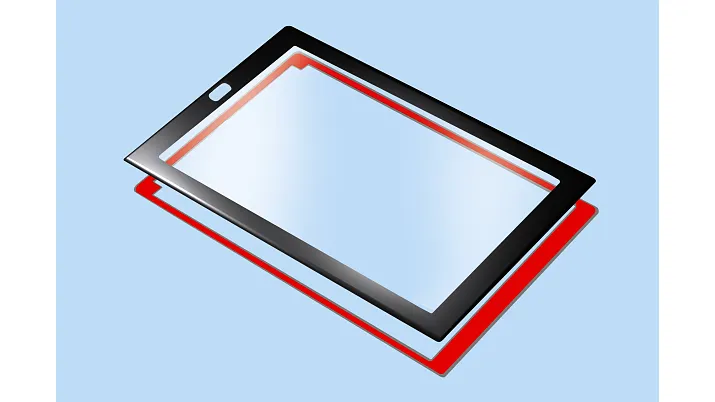

The structure of double-sided PE foam tape with Acrylic adhesive

PE foam tape commonly comes in two popular colors: white & black, with options for single-sided or double-sided adhesive to meet diverse application needs in the industrial sector.

Advantages of Polyethylene (PE) Foam Tape

The main advantages of Polyethylene (PE) Foam Tape include excellent durability, resistance to deformation under load, vibration resistance, shock absorption capabilities, and water resistance.

High bonding strength

Immediate bonding strength

Impact resistance

Sealing, chemical resistance & environmental durability

Shear resistance

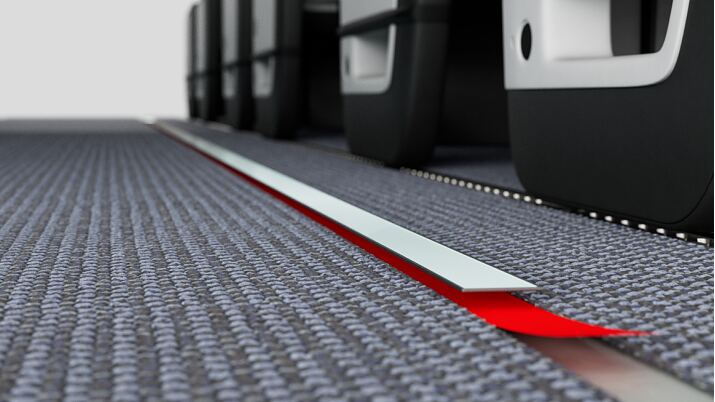

PE foam tape is widely used across various industries, from manufacturing, construction, and automotive to packaging. Its versatility extends beyond these sectors, playing a crucial role in enhancing the quality and efficiency of numerous applications.

PE foam tape is a lightweight foam with a closed-cell structure, offering water resistance, chemical resistance, and high shock absorption capabilities. The adhesive used varies depending on application requirements, with Acrylic commonly used for long-term bonding applications, while rubber adhesive is preferred for temporary applications.

Below are the outstanding advantages of PE foam tape compared to other types of tape:

- Durability: PE foam tape exhibits high durability and can withstand harsh environments, including high temperatures, UV radiation, and moisture. It does not degrade or lose its properties over time, making it a reliable choice for long-term applications.

- Cushioning: PE foam tape provides excellent cushioning ability, protecting surfaces from damage during transportation, assembly, and use. The soft and flexible foam layer conforms to uneven surfaces, providing consistent cushioning.

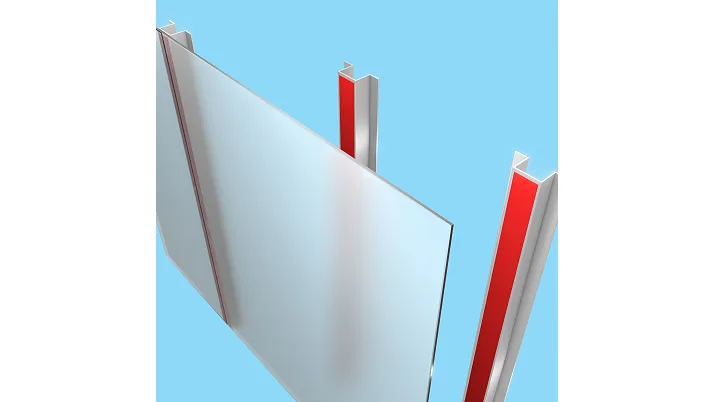

- Adhesion strength: PE foam tape offers strong bonding capabilities suitable for both long-term and temporary applications. The adhesive layer provides secure adhesion to various surfaces, including metal, glass, plastic, and painted surfaces.

- Ease of application: PE foam tape is easy to use and can be cut into any desired shape and size. It is available in various thicknesses, widths, and roll lengths, providing flexibility in usage.

Applications

Manufacturing: PE foam tape is used in manufacturing industries to protect surfaces during fabrication, transportation, and assembly. The foam layer provides cushioning and protection against scratches, dents, and other damages.

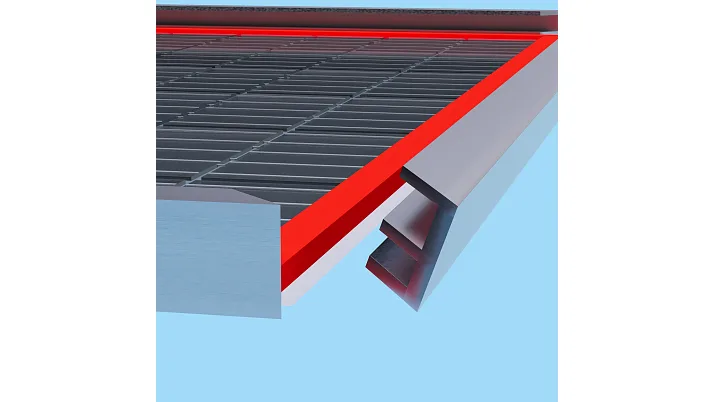

Construction: PE foam tape is used in the construction industry for sealing joints, waterproofing, and insulation. The foam layer acts as a barrier against moisture and air, helping to prevent mold and mildew growth.

Automotive: PE foam tape is utilized in the automotive industry for attaching parts, sealing windows, soundproofing, and vibration damping. The foam layer provides shock absorption and vibration control capabilities, enhancing the driving experience.

Packaging: PE foam tape is employed in the packaging industry to secure goods during transportation. The foam layer offers cushioning and protection against impacts.

Polyethylene foam tape is a versatile and valuable product that enhances the quality and efficiency of various applications. Its excellent properties, including durability, cushioning ability, adhesion strength, and ease of use, make it a preferred choice across different industries. With increasing demand for efficient and reliable products, polyethylene foam tape is expected to witness significant growth in the future.

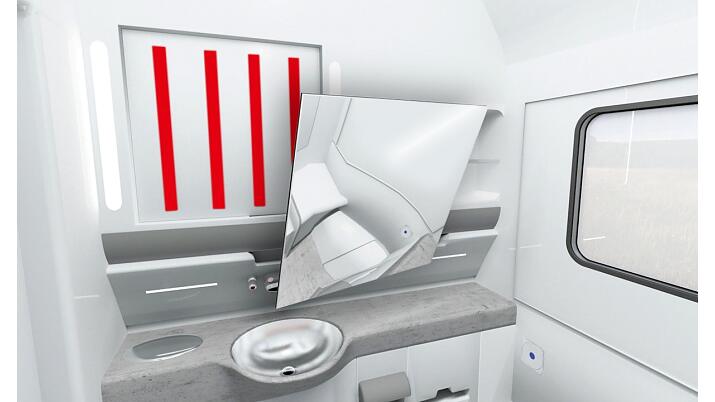

Mirror Mounting Application

Attaching Various Functional and Decorative Components

Decorative Panel

Lens mounting in electronic devices

Mounting of glass panels in construction

Solar frame bonding

Logo

In addition, some types of PE foam tape are specifically designed to serve:

Adhesion on rough surfaces:

For bonding rough or uneven surfaces, Bow Tape’s PE foam tape has the ability to fill gaps and distribute stress evenly across the bonded area.

Bow Tape’s PE foam tapes 398EW (white) & 398a (black) are made from special polyethylene foam material, unique in the market.

Both types of tapes are designed for bonding difficult, rough surfaces. The unique Acrylic adhesive layer ensures strong adhesion and good adaptation to uneven and low surface energy (LSE) materials.

PE foam tape provides strong adhesion to various surfaces from the initial application.

PE foam tape is a reliable alternative to traditional bonding methods such as screws, rivets, bolts, and is more reliable on various surfaces as it does not damage the surface & does not corrode over time.

Packaging applications:

The special properties of the PE foam layer can be used to create a variety of creative packaging designs, providing a high-performance and cost-effective packaging solution.

PE foam is easily converted into custom solutions using traditional processing techniques.

PE foam tape provides excellent protection for products with medium to low levels of breakage because when compressed and released, the PE foam layer returns to its original shape.

Insulation

Polyethylene foam is excellent for insulation. Its flexibility allows for bending and insulation at the same time.

PE foam tape can be adhered to fabric to create flexible coolers. PE foam can also be used for insulating an area in contact with solvents and other petroleum products.

Laminating

Laminating is the process of bonding two or more materials together into layers to create a single composite material, and the applications of PE foam tape in laminating are virtually endless. Some typical examples include:

- Thermal and sound insulation: PE Foam tape has good thermal and sound insulation capabilities, so it is often used to create insulation and soundproofing layers in the laminating process. This helps improve energy efficiency and reduce noise.

- Cushioning and resilience: With its flexibility and resilience, PE Foam tape is a popular choice for creating cushioning layers in the laminating process. It helps reduce shock and protect the surfaces being laminated.

- Thickness enhancement: PE Foam tape is used to increase the thickness of the product after laminating, providing better protection and improving aesthetics.

- Flatness creation: PE Foam tape can be used to create a complete flat surface when laminating different material panels together. This helps enhance durability and ensure product uniformity after the laminating process.

- Shock-absorbing layer creation: PE Foam tape is often used as part of a shock-absorbing layer in the laminating process, helping protect the product from impacts and vibrations during transportation and use.

Buying PE Foam tape

Hitta specializes in providing various adhesives and tapes for both industrial and commercial sectors. Contact us for the most cost-effective and efficient solution advice:

- ☎️ Hotline: 0565 33 68 79

- ✉️ Email: hittajsc@hitta.vn