Discover the essential role of Thermal Interface Materials (TIM) in enhancing the performance of electric vehicle (EV) batteries. Learn how TIM, comprising Thermally Conductive Adhesives (TCA) and gap fillers, regulates battery temperature, improves efficiency, and prolongs battery life.

Demands of the EV Battery Market

As the automotive industry strives to expand the options and availability of electric vehicles (EVs), it is crucial for manufacturers to find high-performance EV battery solutions to meet the growing demand. These batteries, in particular, must offer increasingly optimized performance, such as longer battery life, without compromising manufacturing efficiency.

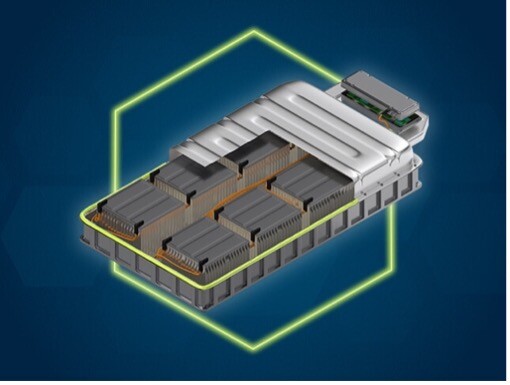

Therefore, it is essential to consider how Thermal Interface Materials (TIM) can help achieve high performance while maintaining efficient production processes. TIM requires Thermally Conductive Adhesives (TCA) to address EV battery optimization needs, as well as thermally conductive gap fillers to protect against overheating from air gaps.

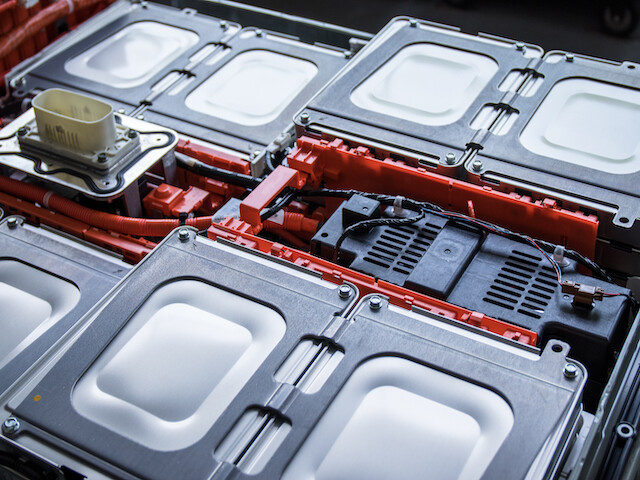

How Thermal Interface Materials (TIM) Support EV Battery Packs

Integrating Thermal Interface Materials (TIM) into the electric vehicle (EV) battery manufacturing process is crucial for prolonging the overall battery lifespan.

When an EV battery is charging, discharging, or in use, heat is generated inside. Lithium-ion (Li-ion) cells, a popular type of rechargeable battery due to their high energy density and light weight, can degrade faster when exposed to high temperatures, resulting in a shorter lifespan.

However, the thermal conductivity of TIM can transfer heat away from the battery cells to a heat sink or semiconductor device. This helps achieve:

Battery Operating Temperature: When heat is properly transferred throughout the EV battery cells, you can easily reach the desired battery operating temperature of 30°C to 40°C, ensuring stability and preventing overheating. Specifically, the battery cell temperature should never exceed 80°C, and the battery charging or discharging temperatures should stay between 0°C and 60°C.

Optimal Battery Performance: By filling air gaps and irregularities between two surfaces, such as between the battery cells and a heat sink, TIM helps reduce thermal resistance and allows heat to flow more efficiently. With these imperfections filled, TIM helps maintain a consistent temperature within the battery pack to prevent overheating or degradation.

Achieving these performance features requires the right Thermal Interface Materials (TIM).

The Importance of Thermally Conductive Adhesives (TCAs) in Thermal Interface Materials (TIM)

Thermally Conductive Adhesives (TCAs) play a critical role in transferring heat away from battery cells and providing electrical insulation to prevent short circuits or overheating within the battery pack, thereby extending the battery’s lifespan.

As a result, TCAs are compatible with other materials used in battery pack assembly, such as electrode materials, current collectors, and casing materials, ensuring that components remain electrically insulated to reduce the risk of electrical faults. Specifically, they offer:

Temperature Resistance: TCAs can maintain performance in a range from -40°C to 150°C, allowing the EV battery to operate at various temperatures during charging, discharging, and usage.

Durability: TCAs protect against degradation with resistance to chemicals, UV light, and humidity. They are formulated to be compatible with metals, ceramics, or plastics, preventing reactions between the adhesive and bonded materials. This compatibility reduces the likelihood of battery maintenance and replacement.

Flexibility: Some TCAs are designed to remain flexible even after curing, accommodating the expansion and contraction as battery components experience temperature changes. Flexible TCAs can absorb stress, reducing the risk of mechanical failure. However, in situations that require stiffness of the structural component, gap filling, high compression, or minimal movement, a TCA with less flexibility may be preferred.

The Importance of Gap Fillers in Thermal Interface Materials (TIM)

Alongside Thermally Conductive Adhesives (TCAs), gap fillers play a crucial role in preventing air pockets, thereby enhancing heat transfer. Minimizing these imperfections allows for overall thermal performance to operate efficiently and extend battery lifespan. Specifically, gap fillers provide:

Hot Spot Protection: Air gaps between the battery cell and heat sink can lead to hot spots, potentially damaging the heat source due to inefficient heat flow. Gap fillers protect these areas where hot spots could occur, helping to maintain consistent heat flow temperatures and prevent overheating.

Conformability: Using liquid, conformable gap fillers allows you to fill microscopic gaps and imperfections between the battery cells and the heat sink that you might not be aware of. Additionally, gap fillers enable more uniform heat transfer by smoothing out surface irregularities.

Recyclability: Gap fillers are removable and repositionable, reducing material waste if repositioning is needed. Furthermore, once an EV battery pack is disassembled, gap fillers can be removed and recycled.

Recommended Solutions

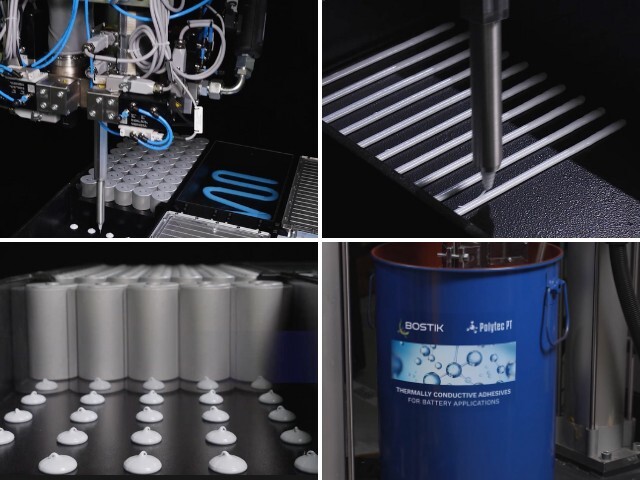

Several technology formulations can work together as Thermally Conductive Adhesives (TCA) and gap filler solutions to create effective Thermal Interface Materials (TIM).

For TCA bonding between the battery cell and cooling plate, two-part epoxy (2K EP) and two-part polyurethane (2K PUR) are recommended:

2K EP TCAs: These are non-silicone solutions often chosen for high-strength bonding, with adjustable properties to meet specific battery design needs. As low-density, non-silicone solutions, they offer a range of viscosities for fast, automated assembly processes. They also provide excellent chemical resistance to enhance the overall battery lifespan.

2K PUR TCAs: These offer thermal conductivity up to 1.5 W/m.K or higher. They are often selected for their heat dissipation capabilities in battery pack assembly, possessing high elongation that enables elasticity for thermal expansion and contraction during heating and cooling. 2K PUR adhesives bond to substrates such as nylon, aluminum, or steel, ensuring components remain electrically isolated to reduce the risk of electrical faults.

For gap filling between a module and cooling plate, 1K non-reactive or 2K silyl modified polymer (SMP) are recommended:

1K Non-reactive Gap Filler: This provides protection for automated processing scalable for high-volume production. As a non-curing, silicone-free solution, 1K gap filler offers an excellent ratio of thermal conductivity to density to prevent air from causing hot spots. This non-hazardous, VOC-free option allows for reworkability and easy dismantling with low oil separation (~0.3%)* over the battery’s lifetime, ensuring long-term stability.

2K SMP Gap Filler: This offers high-volume dispensing and fast compressing due to optimized viscosity levels. Additionally, its viscosity increases fivefold after 90 minutes at 35°C. Usable for automated processes with application times under a minute, this option is silicone-free with no VOCs, reducing environmental impact. It provides easy processing with low compression forces.

Bostik’s 2K PUR TCAs Solution

Bostik has developed a specialized 2K PUR TCA for thermal management in battery pack assemblies. Named XPUTM TCA 202, this 2K PUR adhesive balances thermal management with high mechanical strength while maintaining flexibility due to its high elongation properties. It offers:

Secure Adhesion/Gap Filling: Suitable for plastics, metals, and composites, its low monomer content helps you comply with the most stringent regulations without requiring extensive product training.

Room-Temperature Curing: This reduces overall energy consumption. XPUTM TCA 202 is also quick and easy to process through automatic mixing, dosing, and dispensing equipment without the need for a primer.

Hitta is the authorized distributor for Bostik in Vietnam, specializing in providing specialized adhesives and tapes for both industrial and commercial applications. Contact us for the most effective solutions with the lowest cost.

- ☎️ Hotline: 0565.336.879

- ✉️ Email: hittajsc@hitta.vn