BowTape 300NHK băng keo PET film 2 mặt dày 0.11 mm

Bow Tape 300NHK is a double-sided film tape with a polyester carrier. It exhibits excellent initial adhesion, making it suitable for rough and uneven surfaces. Bow Tape 300NHK offers high adhesion strength and good cutting durability. The quick establishment of bonding strength ensures a strong and long-lasting performance. The tape is UV-resistant and specially engineered to resist plasticizer migration. Notably, Bow Tape 300NHK provides high peel performance without leaving adhesive residue.

Applications: Suitable for various plastic sheets, automotive interior panels, mobile phone cushioning pads, LCD TV touch sensors, vehicle exteriors, door protective panels, and thermal mirrors.

Specifications

| Backing | PET film |

| 180˚ Peel Adhesion | 600 g/10mm |

| Thickness | 0.11 mm |

| Heat resistance | 150˚ |

| Color | Transparent |

BowTape Double-sided film tape

For applications requiring transparent and cuttable adhesive tapes, BowTape introduces a specialized product line to meet these requirements. From PET and PVC films to specially reflective films and Bow Tape’s innovative acrylic film, we can provide any double-sided adhesive film suitable for various business needs.

Strengths:

Diverse double-sided adhesive films, including PET, PVC, and other types of films. Excellent remediation measures and reusability after application. High initial adhesion and relatively high temperature resistance.

Applications:

Use in foam and non-woven fabric applications. Mobile phones, tablets, and other electronic component applications.

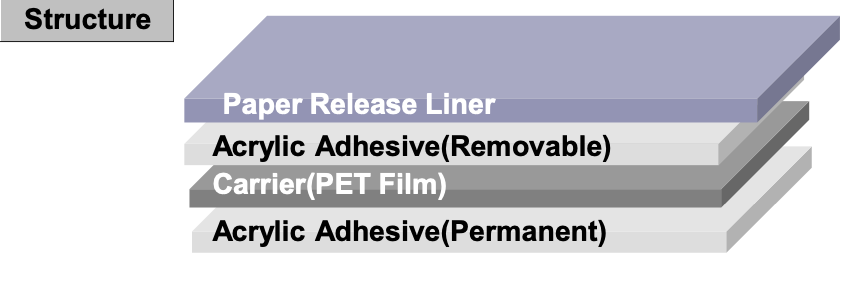

Structure

Performance

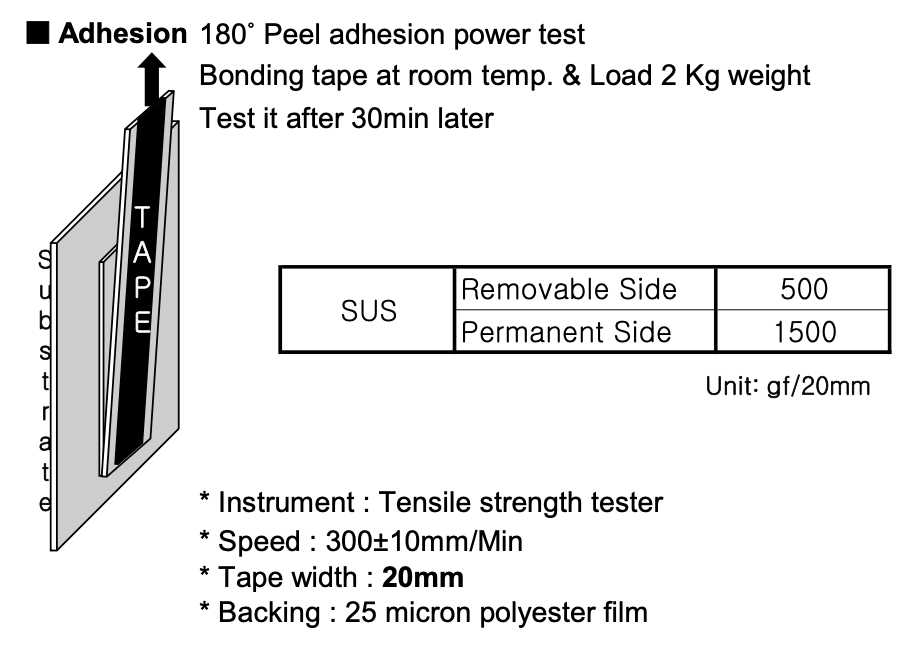

Adhesion test

- The peel-back angle is 180 degrees.

- BowTape 300NHK adhesive tape was pulled for over 2 hours at room temperature.

- Result: Strong adhesion, minimal displacement, passing the test.

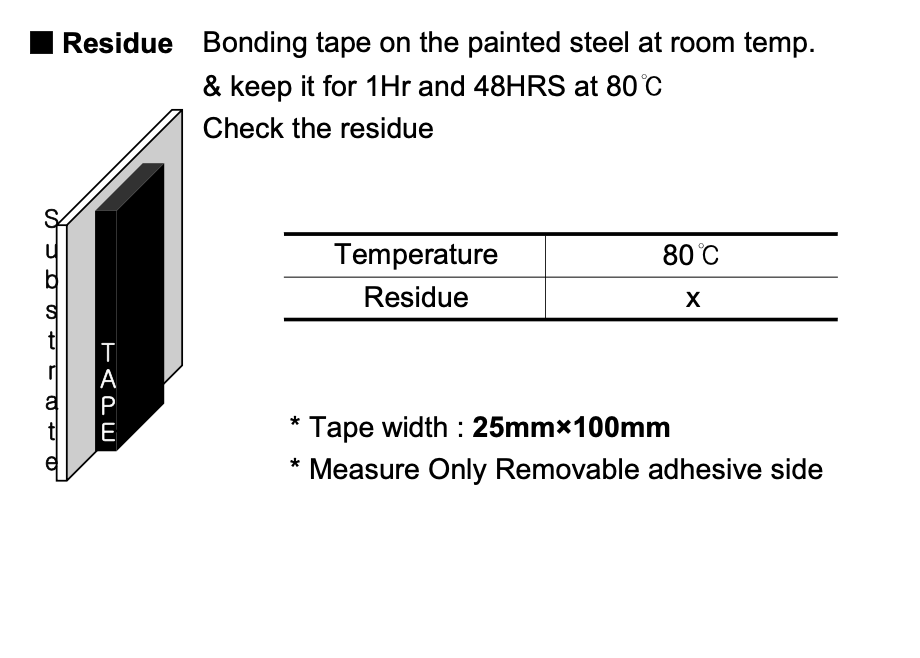

Residue test

- Apply the tape on painted steel at room temperature, hold for 1 hour & 48 hours at 80 degrees Celsius.

- Result: as evaluated in the image

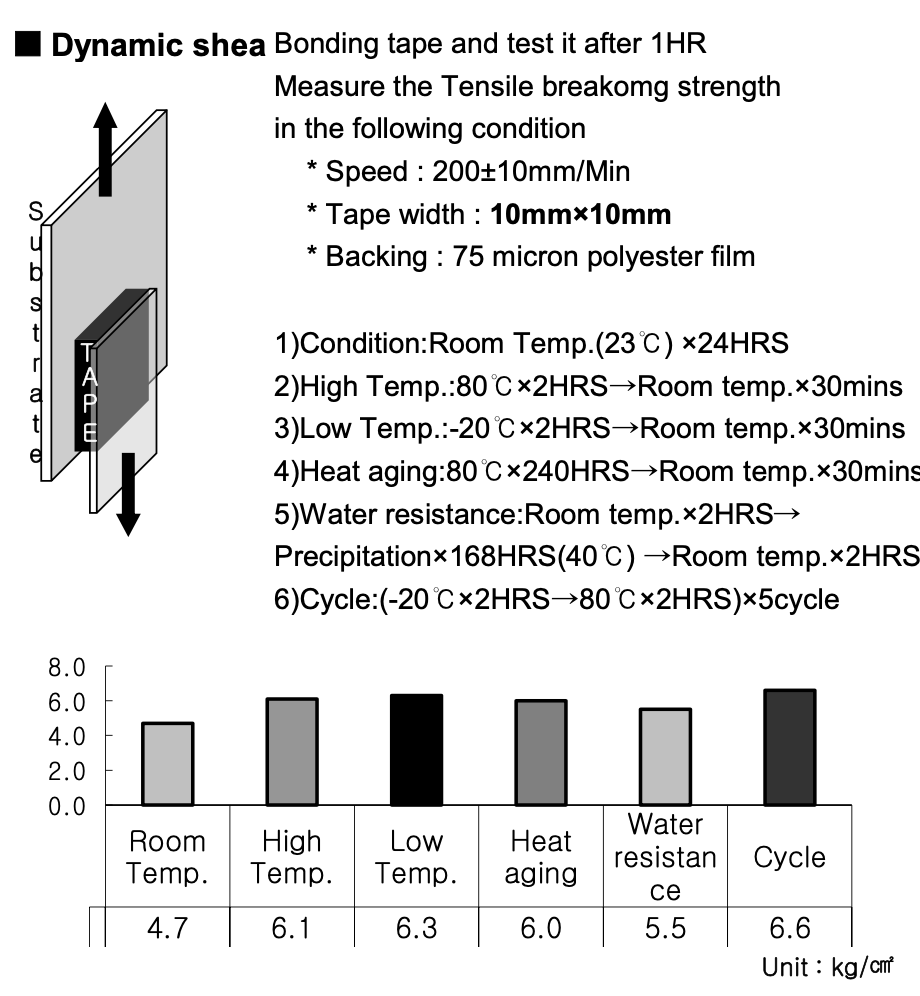

Dynamic shear test

- Withstand tension from 2 sides (top and bottom) at room temperature for over 2 hours.

- Test conditions are described as in the image.

- Result: strong adhesion, minimal displacement, passing the test.

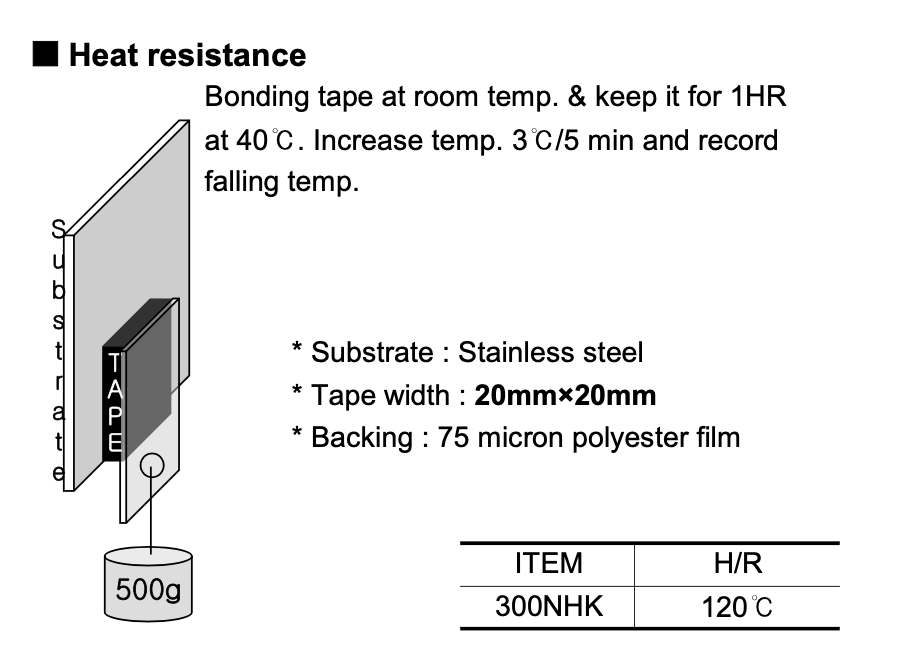

Heat resistance test

- The tape was kept at room temperature for 1 hour at 40 degrees Celsius. Then, the temperature increased by 3 degrees Celsius every 5 minutes with a load of 500g.

- Result: Good performance, as described in the image.