Imagine lighter vehicles that can travel farther with less fuel. More efficient ways to drill and extract oil and insulate pipelines deep under the sea. Paint that helps keep homes cooler on hot sunny days. In all these ways and more, 3M Glass Bubbles are helping a variety of industries tackle challenges in design and achieve superior performance and productivity.

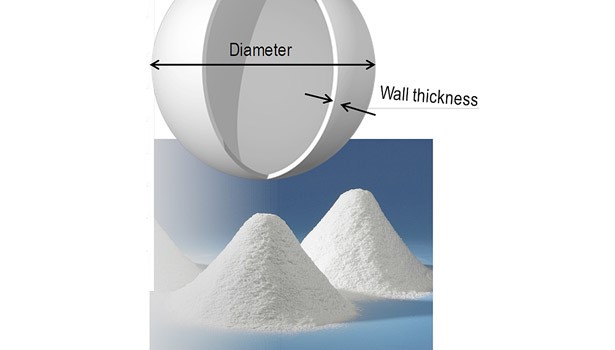

Characteristics of Glass Bubbles

3M Glass Bubbles are hollow glass microspheres made from high-strength borosilicate soda-lime glass. They have a low density and do not have porous openings on the surface. They are chemically stable and exhibit excellent resistance to water and oil. 3M Glass Bubbles have sufficient rupture strength to be suitable for various manufacturing processes and can be compatible with a variety of polymer systems. In addition to reducing weight, 3M Glass Bubbles offer other benefits such as:

- Resistance to shrinkage, insulation.

- Reduction in the use of plastic.

- Light reflection.

- Low dielectric constant.

Applications of 3M Glass Bubbles

3M Glass Bubble for Paint and Coating Industry

3M Glass Bubbles and 3M Ceramic enhance abrasion resistance, reduce thermal conductivity, and improve the efficiency of various coating systems. They are used in interior paints to prevent condensation and in exterior paints to reflect solar heat, slowing down condensation, reducing moisture buildup, inhibiting mold growth, and regulating indoor temperature for increased comfort. In anti-corrosion coatings, 3M Glass Bubbles protect surfaces from environmental damage and improve washability and scratch resistance in both interior and exterior paints.

3M Glass Bubble provides a cost-effective alternative to conventional fillers in many specialized coating applications. These hollow glass microspheres serve as lightweight, low-density fillers that reduce the weight and viscosity of coating formulations. They offer multiple functional benefits, from scratch resistance to sunlight reflection.

- Acrylic Paint and Industrial Rubber Paint

- Solar Energy Reflective Roof Coating

- Epoxy Paint

Highlighted Advantages of 3M Glass Bubble in Paints and Coatings:

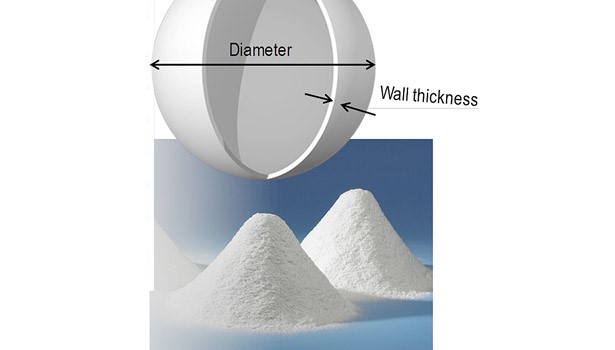

With a variety of glass bubble types available with different crush strengths, densities, and particle sizes, 3M Glass Bubble can meet various performance requirements and production processes to optimize your needs.

High crush strength, low density, and unique physical properties offer several advantages over coatings formulated with conventional fillers:

- Improves abrasion resistance (depending on the product type).

- Reduces thermal expansion and contraction.

- Uniform spherical shape improves flow properties and ease of application.

Cost Savings:

- Using paint formulations with 3M Glass Bubbles can reduce costs per liter of paint while helping control maintenance and operating expenses.

- Lower cost per volume compared to conventional fillers.

- Allows loading higher filler content, reducing the need for expensive resins.

- Solar energy reflective coatings help maintain cooler indoor temperatures, reducing cooling costs.

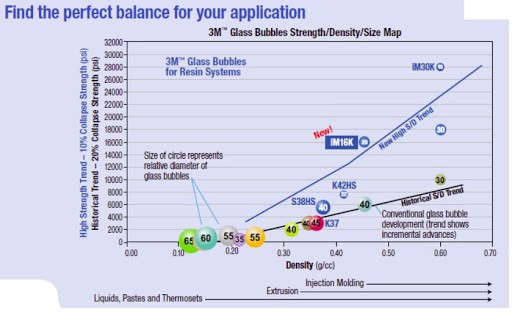

Thermal Insulation/Cooling Paint

With the Earth’s increasing temperatures, the concept of staying cool is not just about comfort anymore. Effective solar energy efficiency can significantly impact your profitability. Tests have shown that roof coatings formulated with 3M Glass Bubble Glass Bubbles can offer several performance and cost benefits compared to typical “cooling” paint coatings.

- Higher total solar reflectance.

- Higher thermal emittance (ability to self-cool).

- Lower interior temperatures.

- Reduced cooling costs.

In addition to traditional use in building products to save energy, solar reflective paint is expanding into new and exciting areas such as marine vessels or containers.

3M Glass Bubble for Rubber and Plastic Industry

More comfortable shoes. More fuel-efficient cars. Environmentally sustainable packaging. In all these ways and more, a small product is making a big difference. 3M Glass Bubble is helping OEM manufacturers and end-users by creating lighter and dimensionally stable plastic and rubber products, faster processing, and less waste.

Low-density, high-strength glass microspheres are used as lightweight fillers in various polymers and applications. These hollow glass microspheres help reduce the final product’s weight while maintaining or improving processing and physical properties. 3M Glass Bubbles are designed to withstand the temperature and pressure of compounding, injection molding, extrusion, etc. They can be used for a variety of different plastic systems, including:

- Polyolefins, nylon, and other thermoplastic resins

- Thermoset plastics

- Rubber

- Wood-plastic composites,…

There are hundreds of current and potential applications for 3M glass bubbles, and their benefits extend beyond just lightweighting. Their spherical shape and material properties offer some unique improvements to help you achieve your product weight reduction goals.

Weight Reduction

3M Glass Bubbles can reduce weight by up to 15% or more in many polypropylene systems and 18% or more in glass fiber-reinforced polyamide products without significant changes to material, design, or processes, helping to reduce transportation costs for lighter-weight products. Plastic systems using 3M Glass Bubbles can also contribute to environmental sustainability through better fuel savings.

Product Dimensional Stability

3M Glass Bubbles help improve dimensional stability for both large and complex parts. Their spherical shape and low density allow for higher filler loading, which can improve product stiffness. They also allow the molten polymer to cool uniformly throughout the part, helping to prevent microcracks and shrinkage.

Shortened Processing Cycles

Long cooling times in injection molding and extrusion processes can limit manufacturing capacity and increase costs. Low-density 3M Glass Bubbles displace mass that would typically need to be melted and cooled. The result is faster-cooling products: up to a 15–25% reduction in cooling time in production-scale applications. This means higher productivity and more efficient manufacturing processes.

Other Benefits

Depending on the application, 3M glass bubbles can offer various other benefits. They can be used to improve thermal insulation, increase buoyancy, and reduce permeability. They enhance solar energy reflection properties and can be utilized for custom aesthetic effects. They can also enhance abrasion resistance and the drill/nail resistance of wood plastic composites.

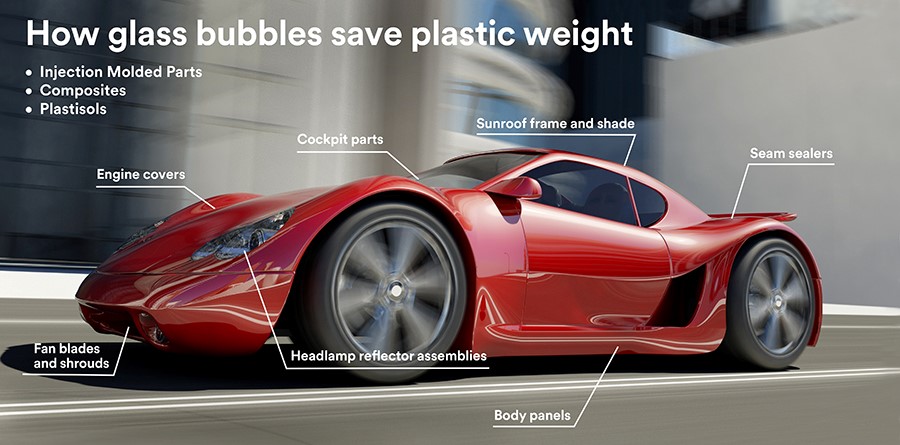

3M Glass Bubble for Automotive Industry

Low-density plastics help save fuel for vehicles. According to calculations, every 10% reduction in vehicle weight can lead to a 5-7% decrease in fuel consumption. In the current economic and environmental context, creating fuel-efficient vehicles is a top priority for the automotive industry. While advanced materials like aluminum or carbon fiber are useful, utilizing plastics, especially low-density plastics, has significantly improved for several reasons:

- Corrosion resistance, prolonging the lifespan of vehicles.

- Easy to design and mold, allowing for the creation of aesthetically pleasing designs.

- Safe, convenient, and cost-effective.

- Can be recycled.

Today, reducing the density of plastics has become essential. With products like 3M Glass Bubble with ultra-lightweight density (0.1-0.6kg/cm3) and high durability, significant improvements have been made in reducing the density of plastic components in vehicles while maintaining their mechanical and chemical properties.

They help improve the density of plastics by up to 25%. Currently, major automotive companies worldwide such as Toyota, Hyundai, Mercedes-Benz, etc., have widely adopted them in various plastic components in vehicles.

What are 3M Glass Bubbles?

3M Glass Bubbles are hollow glass microspheres made from high-strength, low-density borosilicate soda-lime glass. They do not have pores on the surface, are chemically stable, and have excellent water and oil resistance. 3M Glass Bubbles have sufficient strength to be suitable for various manufacturing processes and can be compatible with many different polymer systems.

Applications of 3M Glass Bubbles

The applications of 3M Glass Bubbles are numerous and diverse, including the paint and coating industry, rubber and plastic industry, automotive sector, and more.

Can 3M Glass Bubbles be used for thermal insulation paint?

Yes, they can. With their thermal reflection and insulation properties, 3M Glass Bubbles can be used for heat-resistant or thermal insulation paint. These hollow glass microspheres are utilized as additives to reduce density, weight, and viscosity in paint formulations. They contribute various functional benefits, ranging from scratch resistance to solar light reflection. Additionally, they are used in various types of paint, such as acrylic paint, industrial rubber paint, solar energy reflective roof coatings, and epoxy paint.

Related article: