Specialized windshield adhesive requires no primer, provides strong bonding, high durability, fast installation, and helps increase efficiency and optimize costs for assembly and manufacturing.

Advantages of the Solution:

- No need for black primer.

- Meets all long-term durability requirements.

- No need for heat, instant application.

- Stronger than old bonding materials by 3 to 50 times.

- Urethane bonds well with smooth surfaces like glass and harder surfaces like automotive metal and paint.

- UV, chemical, and water-resistant.

- High tensile strength in automotive applications.

- High shear strength in automotive applications.

- Non-conductive – reduces electrical interference.

Meets Industry Requirements:

Since windshields perform multiple functions beyond just shielding from rain and wind, specifications from automotive manufacturers and assemblers can only be met by adhesives.

Strong Bond: meets the high durability requirements set by vehicle manufacturers to ensure the windshield can perform all safety functions effectively.

Stiffness: integrating the structure into the windshield increases stiffness, allowing automotive manufacturers to save weight by reducing the thickness of metal sheets.

Durable: withstands harsh conditions such as desert and tropical climates, salt from seawater, or winter conditions.

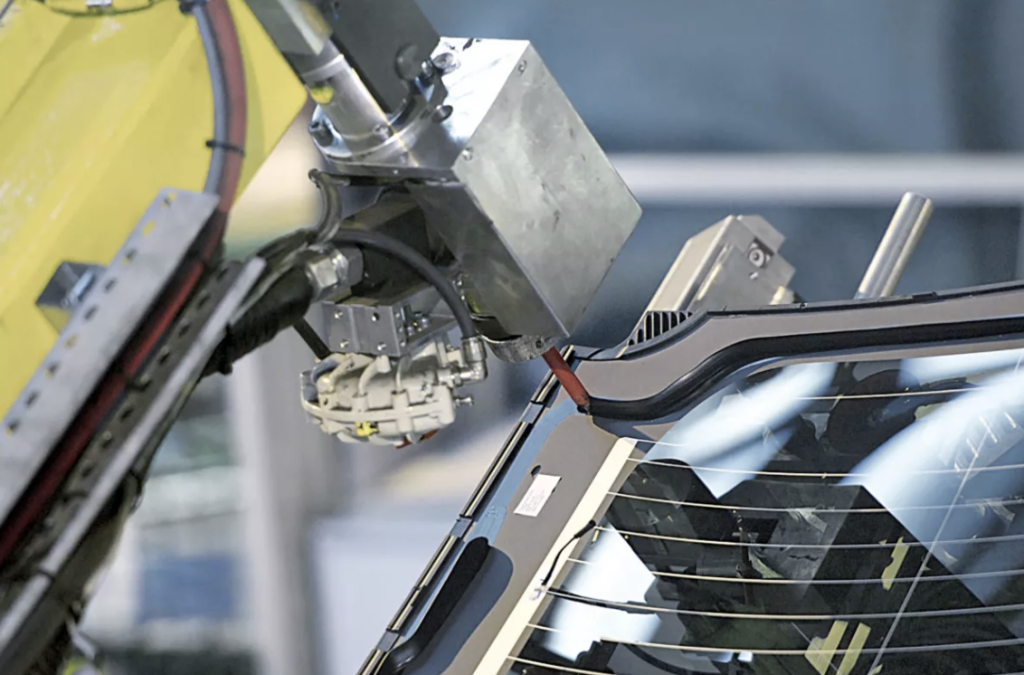

Quick Process: allows for fully automated windshield installation at the factory.

Hitta provides a windshield adhesive solution for automobiles that does not require primer, sets quickly, and offers longer durability compared to other products in the same segment on the market. Additionally, the product meets safety and health standards.

Automated Application of Car Windshield Installation

Automotive Windshield Adhesive

The windshield of an automobile is an indispensable part of its structure, design, and safety, as it serves as the front-facing glass for the driver, acting as a barrier in case of accidents. Therefore, requirements for durability, hardness, and functioning as a force shield for airbags during accidents must be met.

Automobile manufacturers have utilized the stiffening effect of glass to increase the overall stiffness of the vehicle, enhancing safety while reducing the thickness of steel and the weight of the car.

Regarding processing, advancements such as adhesive bonding without black primer or extended open time primer have significantly reduced the complexity of bonding. The adhesive is applied directly, allowing the windshield to be immediately secured in place, enabling automated installation processes in factories.

These unique characteristics, combined with the most cost-effective performance ratio, mean that all automobile manufacturers rely on polyurethane adhesive for windshield bonding.

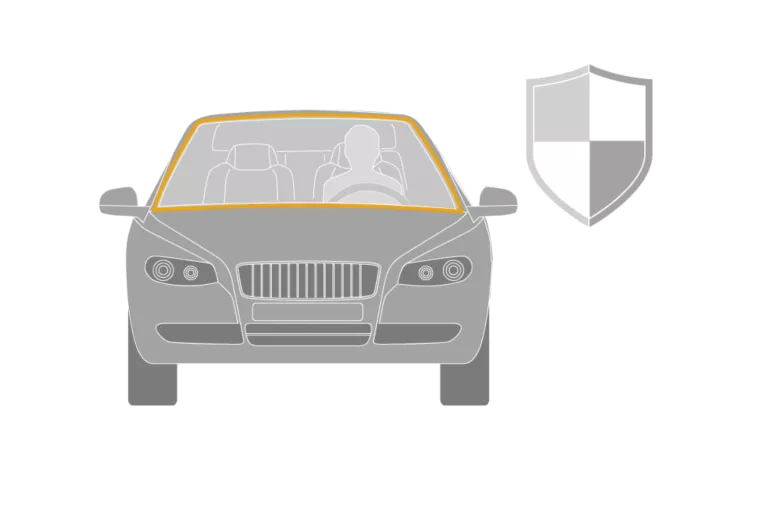

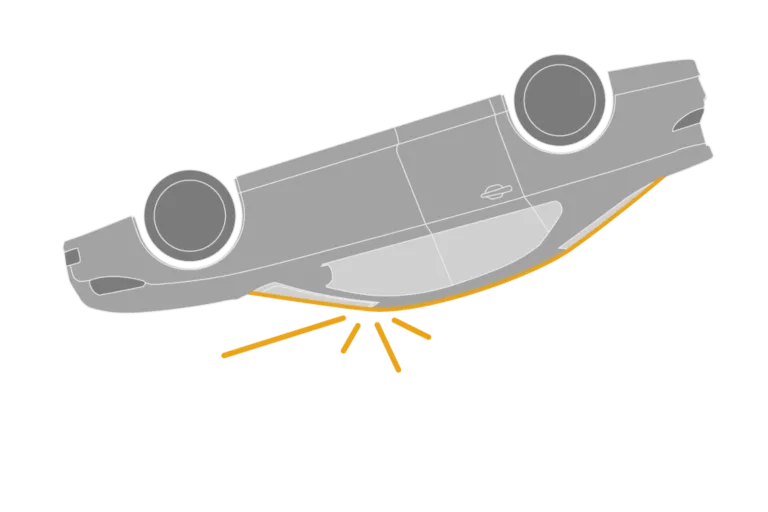

Preventing Driver Ejection: Windshields and their bonding are designed to prevent the driver from being ejected from the vehicle in the event of a collision. This aspect is part of the crash tests that automobile manufacturers are required to conduct before releasing a vehicle.

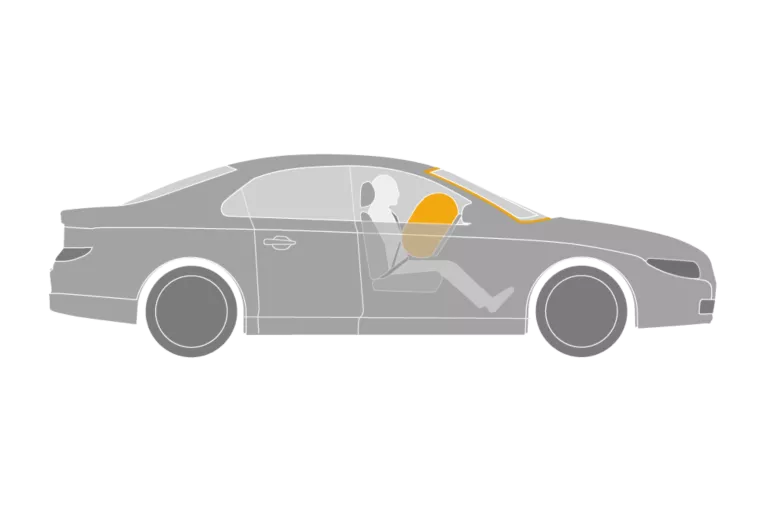

Rear Shield for Airbags: In many cars, the windshield comes into contact with the force of the airbag and the occupants of the vehicle. It needs to stay in place and keep the passengers inside the car.

Preventing Roof Crush: Since the windshield is a structural component of the vehicle body, it must prevent the roof of the car from crushing in the event of a rollover accident.

Windshield Adhesive for Trucks

Similarly to cars, windshield adhesive for trucks meets all industry requirements.

Adhesive for railway vehicle windshields

The requirements for adhesives used in assembling glass and other railway components differ significantly from those for passenger cars. Once again, polyurethane is the predominant technology, and for many valid reasons:

Bonding Strength: The loads in railway carriage designs are significantly greater than those in passenger cars. Managing these forces while still maintaining small joints (design aspects) is imperative.

Durable: Railway carriages are manufactured to endure over 30 years. Polyurethane can withstand the harshest conditions such as desert or tropical climates, or salt from seawater, the best.

Resistance capability: Railway operators use strong cleaning agents to remove dirt such as brake dust, corroded contact wires, and graffiti.

Process optimization: Adhesives capable of solidifying large joints, which are common in the railway industry.

Adhesive for bus windshield bonding

The same requirements also apply to public transportation vehicles such as buses.

Contact Information

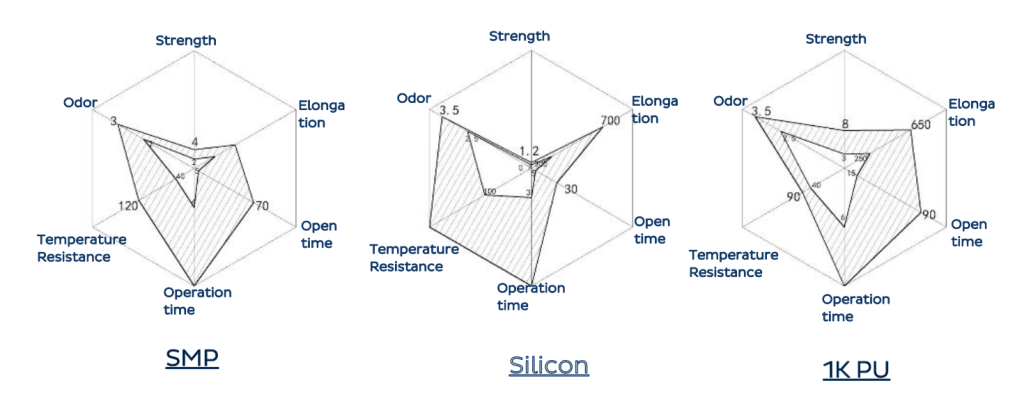

Hitta is pleased to introduce high-quality adhesives based on Silyl Modified Polymer (SMP), specially developed for windshield bonding applications in the automotive industry.

So sánh SMP , Silicon & PU

The advantages of Bostik 7008 adhesive include:

- Quick and efficient curing, suitable for bonding various materials in OEM, automotive assembly, mobile assemblies, especially in applications where installed parts will move immediately after production.

- Compliant with FMVSS212 standards.

- Utilizes Dual SMP technology to ensure increased and controlled curing speed and reliability during production, enhancing application capabilities.

Hitta specializes in providing various types of specialized adhesives and tapes for both industrial and commercial sectors. Contact us for the most efficient solutions at the lowest cost:

- ☎️ Hotline: 0565 33 68 79

- ✉️ Email: hittajsc@hitta.vn