Reliable adhesive solutions play a crucial role in enhancing the operational efficiency of refrigeration devices in general and household refrigerators and freezers in particular. Adhesives serve an indispensable function in the manufacturing process, ensuring that components are securely bonded. As adhesive technology advances, the performance and longevity of refrigerators also improve.

Adhesives fulfill numerous functions, from exterior decoration to sealing essential parts, increasing energy efficiency, reducing the need for frequent maintenance, and enhancing the overall quality of the appliance.

Refrigerator Manufacturing Process

Recent innovations in refrigerator manufacturing have led experts to predict that the market value will reach $125 billion by 2025. These technological advancements in the manufacturing process are enabling refrigerators to be cheaper, more energy-efficient, and produced faster.

The refrigerator manufacturing process can be broken down as follows:

Exterior Cabinet and Door

This stage involves folding and joining two or more metal sheets, which are then painted to form the exterior cabinet. Commercial refrigerators typically use stainless steel for the exterior cabinet to ensure maximum hygiene.

Interior Cabinet

The interior of the refrigerator is made from plastic, shaped through vacuum forming. Traditionally, metals similar to those used for the exterior were utilized for the interior compartments, but plastic is now always used for the inner linings.

Sealant is applied at this stage to enhance insulation and aesthetics. The interior cabinet is fitted into the exterior cabinet using polyurethane foam, which expands when heated in an oven to increase the structural rigidity.

Cooling System

The cooling unit, including the compressor, evaporator, and condenser, is attached to the cabinet. Copper tubing is used to connect the components within the cooling system.

The Role of Adhesives & Sealants in Refrigerator Manufacturing

Adhesives offer numerous advantages over traditional bonding techniques, making them the top choice for the repair, assembly, and production of refrigerators. The benefits of adhesives include:

- Effective across a wide temperature range; from -65°C to 232°C.

- Dielectric properties under broad thermal cycles.

- Capability to form strong bonds with various surfaces and materials.

- Environmentally friendly and sustainable.

- Fire-resistant with low flammability.

Especially for manufacturers, specialized adhesives and sealants for refrigerators can be used to bond plastic-to-plastic or plastic-to-metal joints and to attach silicone rubber gaskets to the casing.

Recommended Characteristics of Adhesives & Sealants:

- High performance, curing at room temperature.

- Cure to a tough, flexible rubber ideal for bonding metal to plastic parts in refrigerators, providing primerless adhesion to steel, aluminum, ceramics, and glass.

- Some transparent sealants are ideal for providing non-corrosive gaskets in areas requiring high flexibility, such as refrigerator doors, are easy to apply, and offer excellent adhesion without the need for a primer on many surfaces.

- Low or no odor.

- Adheres to various surfaces.

- Available in a variety of colors to match refrigerator finishes such as white, black, clear, aluminum/metallic.

Bostik: Leading Provider of Specialized Adhesive Solutions for Refrigerators

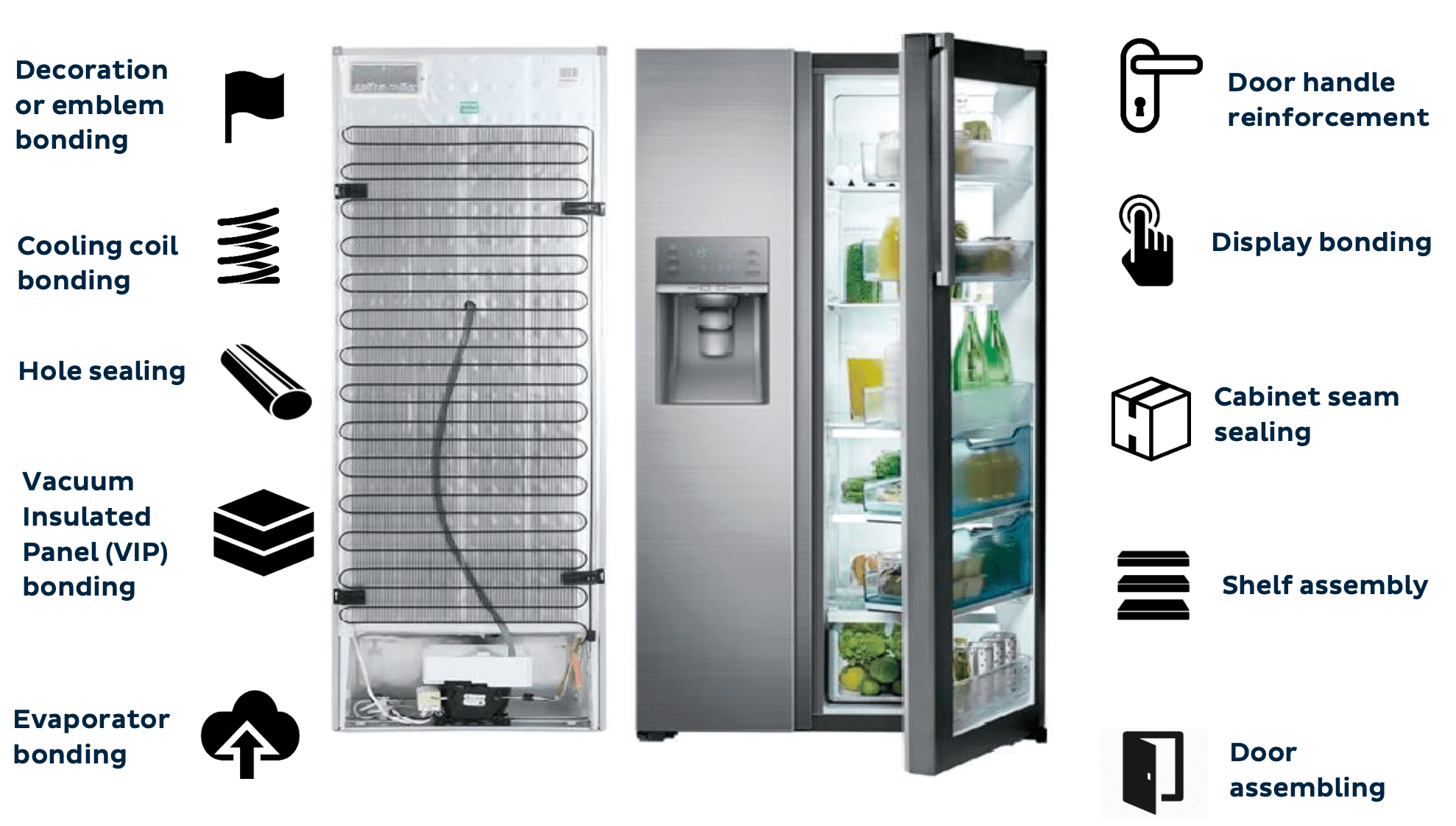

Bostik is a leading provider of specialized adhesive solutions for refrigerators, with applications including:

- Bonding decorative elements or logos.

- Attaching cooling coils.

- Sealing holes.

- Bonding vacuum insulation panels (VIP).

- Bonding evaporator components.

- Reinforcing door handles.

- Bonding displays.

- Sealing cabinet seams.

- Assembling trays.

- Assembling refrigerator doors.

Bonding Cooling Coils

To meet new energy-saving standards, refrigerators and freezers must achieve excellent thermal efficiency. Therefore, sealing between the cooling coil and the refrigerator is crucial.

The smart adhesive solution provided by Bostik through Hitta offers:

- Excellent thermal conductivity.

- High flexibility: suitable for hot and cold applications.

- Manual or automatic application.

- Proven effective solution.

| Ranking | Adhesive Technology | Description | Benefits |

|---|---|---|---|

| Best | Hot Melt Butyl | Butyl applied hot directly onto the cooling coil | Excellent thermal conductivity. Allows elimination of all tapes. Energy-saving: application at low temperatures. |

| Better | Butyl Paste | Butyl applied cold directly onto the cooling coil | Proven solution. Optimal for manual application (using glue guns). Versatile: adheres to various surfaces. |

| Good | HMPSA | Hot melt pressure-sensitive adhesive applied between coil and aluminum foil | General-purpose application: adheres to various substrates. High initial tack for quick processing. No need for tapes. |

Please contact Hitta for personalized product advice that best suits your process.

Seam sealing

Seam sealing involves filling gaps in refrigerators with adhesive. It is essential to prevent polyurethane foam leakage during the thermal spraying process.

The smart adhesive solution from Bostik provided by Hitta offers:

- Cost reduction: up to 60% savings through on-site foam technology.

- Reduced adhesive excess and residues during manufacturing.

- Decreased manual labor and cleanup efforts.

| Ranking | Adhesive Technology | Description | Benefits |

|---|---|---|---|

| Best | Foamable Hot Melt | Rubber-based hot-melts are formulated to have the right level of adhesion, allowing for ease of application and removability. | Up to 60% density reduction from foaming. Excellent adhesion on multiple surfaces. Low temperature application: around 100-110°C. |

| Better | HM EVA | EVA are suitable for a large range of substrates and running temperatures, while being the most affordable adhesive solution. | Foamable adhesive for material cost reduction. Short drying time: fast automatic process. |

| Good | Butyl Putties | Butyl lubricant putty applied cold into gaps in the refrigerator | Permanent plastic and tacky. Aging and weather resistance. Odor-free at room temperature. |

Please contact Hitta for personalized product advice that best suits your process.

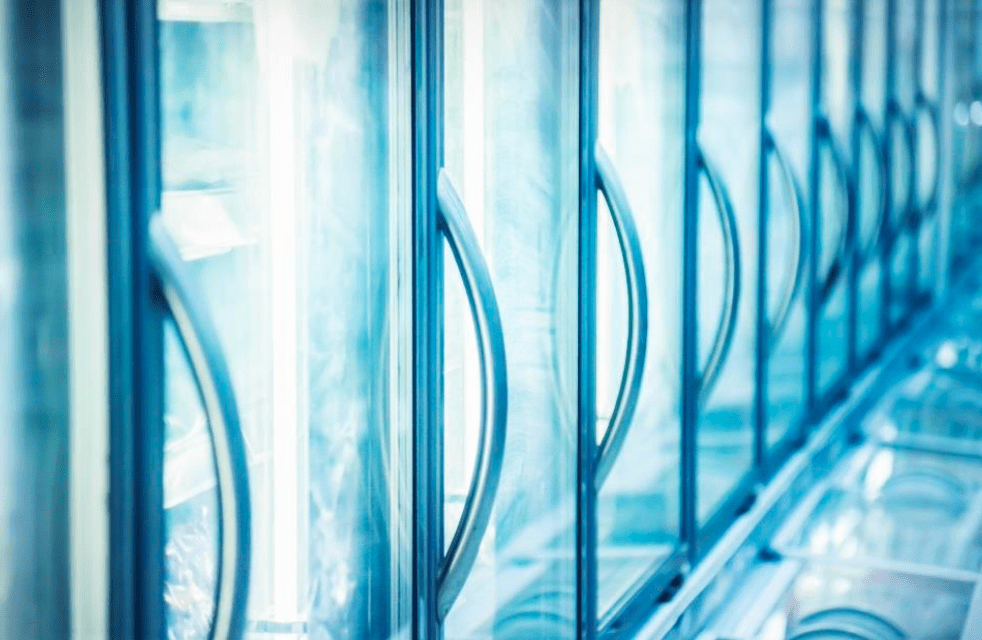

Door assembly

The door is the outer shape of the refrigerator. Sometimes it can be transparent using glass, or opaque by attaching a metal or plastic panel. Therefore, various substrates are needed to bond for door assembly.

The smart adhesive solution from Bostik provided by Hitta offers:

- Comprehensive solution: can assemble all types of doors.

- Easy-to-use adhesive suitable for both manual and automated applications.

| Adhesive Type | Features | Details |

|---|---|---|

| PU 2K | Rapid curing at room temperature. High flexibility and structural integrity with adjustable processing speeds. | Short and long open times available. Suitable for both manual and automatic applications, horizontal and vertical. Cures at ambient or high temperatures. |

| HM PU | Reactive hot melt adhesive that forms permanent bonds resistant to high temperatures by reacting with moisture. | – Immediate bonding. – Adheres to all surfaces. – Non-sagging, easy to apply. |

| HM PSA | Designed to provide suitable adhesive strength, offering various PSA levels (including removable and permanent types). | – Adheres to a wide range of substrates (e.g., plastics like ABS, PC, PVC, PET, or painted sheets). – Low odor. – High initial tack for fast processing. |

| HM EVA | Ideal for bonding interior door gaskets, providing the most practical bonding solution. | – Fast application time. – Adheres well to difficult surfaces. – Outstanding thermal stability. |

Please contact Hitta for personalized product advice that best suits your process.

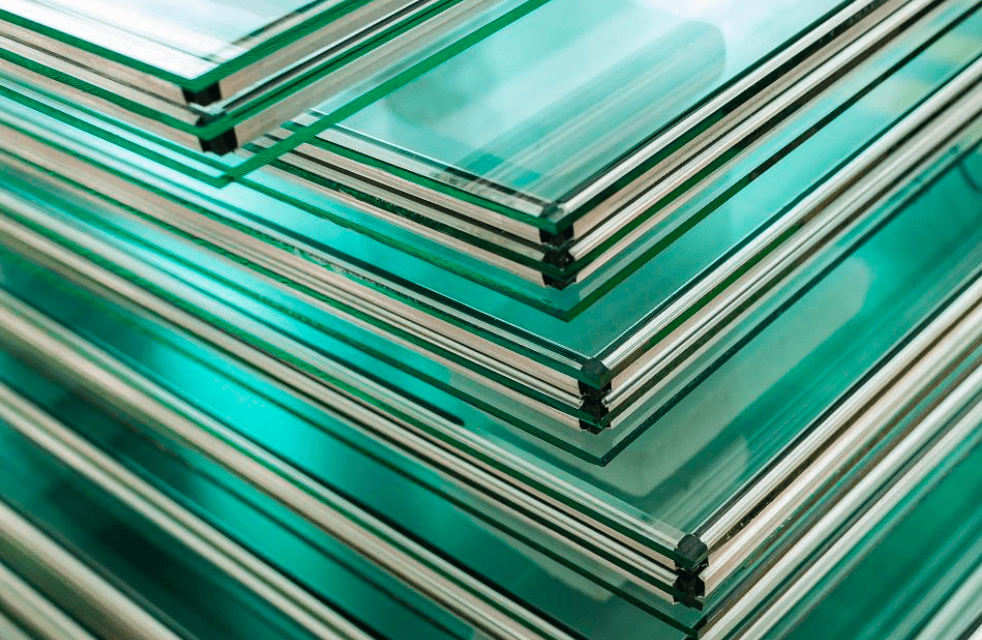

Insulated Glass

Many refrigeration appliances utilize transparent glass doors (such as in commercial refrigerators and freezers). Bostik is a leading company in Hotmelt for thermal glass bonding applications. To minimize maximum temperature, thermal glass with two layers of glass is used.

| Ranking | Adhesive Type | Description | Benefits |

|---|---|---|---|

| Best | HM Butyl | Butyl Hot Melt used by robots in automation. This adhesive offers excellent adhesion to various substrates and acts as a good thermal barrier. | – Low moisture vapor transmission rate (MVTR). – Low air permeability. – Excellent adhesion to gaskets and glass. |

| Good | HM PUR | Specialized HMPUR adhesive used for thermal insulation glass bonding, curing via one-component moisture reaction. | – Low moisture vapor transmission rate (MVTR). – Excellent adhesion to various substrates. – Excellent integrity at both low and high temperatures. |

Please contact Hitta for personalized product advice that best suits your process.

Other applications

We recognize that the appliance industry, especially in refrigeration and air conditioning, is considerably more complex than some of the applications previously discussed.

Nevertheless, Hitta provides comprehensive solutions to meet all your processes. Let us know your application, and we’ll always have specialized adhesive solutions tailored to those needs.

Adhesive Selection Consultation

| Application | Hot Melt EVA / Olefin | Hot Melt Pressure Sensitive | Foamable Hot Melt | PU | SMP | Butyl |

| Coil bonding | ✔ | ✔ | ||||

| Seam sealing | ✔ | ✔ | ✔ | |||

| Hole sealing | ✔ | ✔ | ✔ | |||

| Decorative bonding | ✔ | |||||

| Door assembly | ✔ | ✔ | ✔ | |||

| VIP bonding | ✔ | |||||

| Evaporator bonding | ✔ | |||||

| Door handle reinforcement | ✔ | ✔ | ||||

| Display bonding | ✔ | ✔ | ✔ | |||

| Shelf assembly | ✔ |

recommended products

Hitta is the authorized distributor for Bostik in Vietnam, specializing in providing specialized adhesives and tapes for both industrial and commercial applications. Contact us for the most effective solutions with the lowest cost.

- ☎️ Hotline: 0565.336.879

- ✉️ Email: hittajsc@hitta.vn