How can regular paint be transformed into heat-resistant, heat-insulating paint? It’s quite simple, with advanced technology from the United States, Hitta will assist you.

Heat-resistant paint is an extremely popular solution for reducing the temperature inside a house, commonly used for metal roofs, tiled roofs, outdoor house walls, cement surfaces, concrete, etc. Therefore, heat-resistant paint is no different from regular paint, with the added advantage of reducing the transmission of heat into the interior of the house. This difference is created by the composition and materials of the paint.

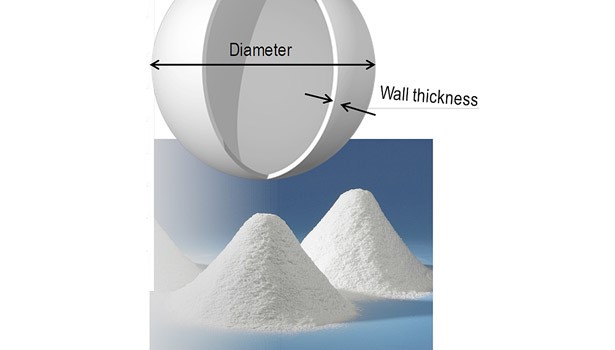

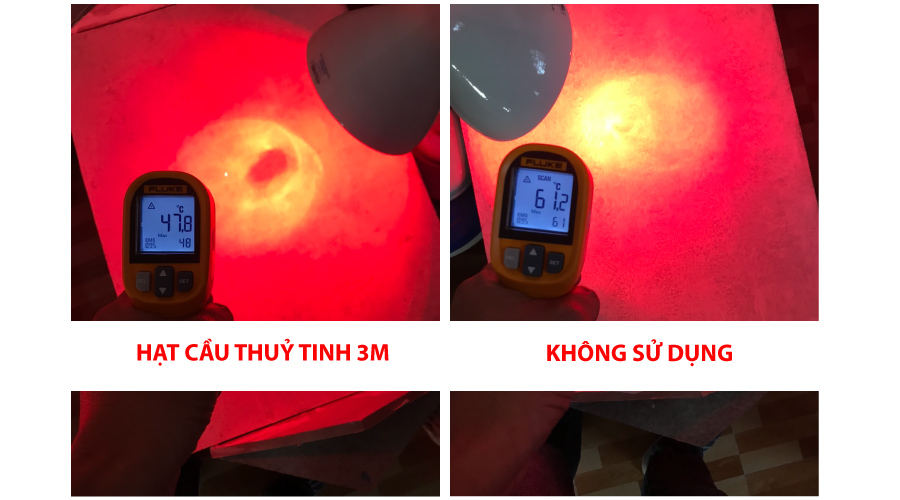

The 3M glass microspheres or 3M bubble glass provided by Hitta are an advanced technology material from the United States that offers an extremely effective heat-resistant solution for paint. Let’s explore together.

Understanding Heat-Resistant Paint

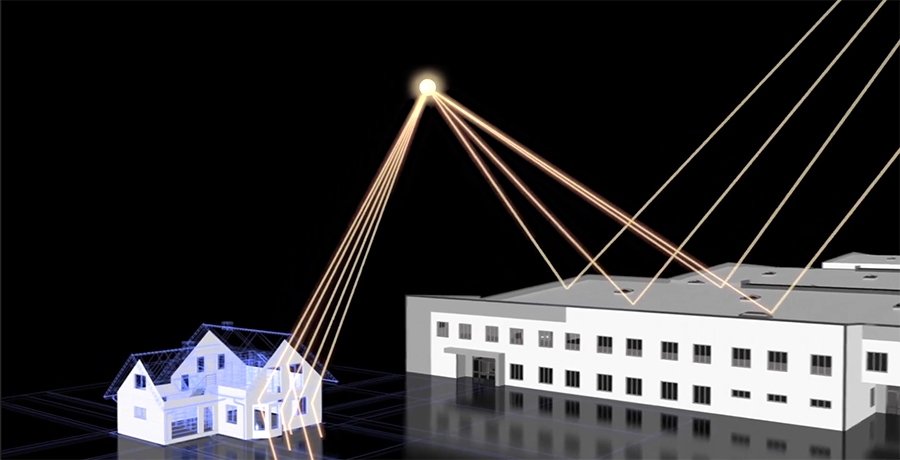

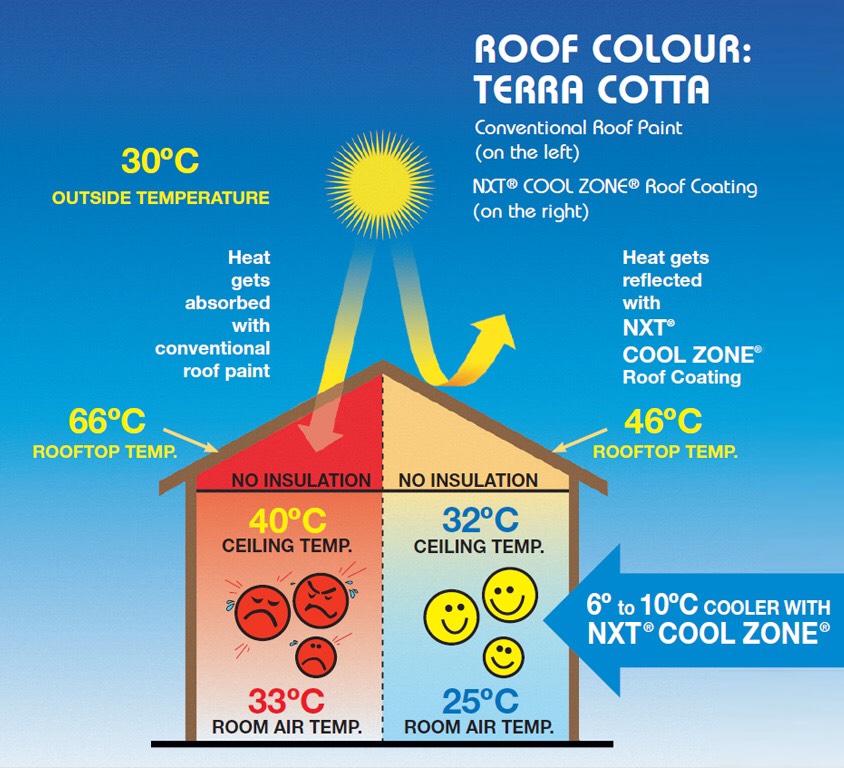

Heat-resistant paint, in simple terms, is paint that helps reduce the temperature of the surface it covers, whether directly or indirectly exposed to sunlight. Heat-resistant paint is one of the most effective solutions because of its ability to cover the entire exterior, thereby reducing the temperature for the entire house, saving energy, and reducing electricity bills from using appliances such as air conditioners, coolers, misters, etc.

From a technical perspective, heat-resistant paint works based on two mechanisms: heat reflection and insulation. Therefore, in the market, heat-resistant paint is also commonly referred to by two other names: heat-reflective paint (or light-reflective paint) and insulating paint.

Creating Heat-Resistant Paint from Regular Paint

As mentioned earlier, the formulation of the paint plays a crucial role in determining its ability to resist heat, both in terms of thermal reflection and insulation. When mixed into the paint, 3M glass microspheres provide the paint with both thermal reflection and insulation capabilities, which are superior features in today’s market.

Sample heat-resistant paint formula:

3M Bubble glass S22

| Raw Material | Density (g/cc) | Weight | Weight (%) | Volume (%) | Dry Volume (%) |

|---|---|---|---|---|---|

| Water | 1.00 | 47.64 | 22.18 | 23.82 | 0.00 |

| Wetting & dispersing agent | 1.16 | 0.87 | 0.40 | 0.37 | 0.23 |

| TiO2 | 4.10 | 61.50 | 28.62 | 7.50 | 15.00 |

| Acrylic resin dispersion | 1.09 | 81.88 | 38.11 | 37.56 | 31.72 |

| 3M Glass Microspheres S22 | 0.22 | 11.00 | 5.12 | 25.00 | 50.00 |

| Thickening agent 1 | 1.05 | 2.21 | 1.03 | 1.05 | 1.00 |

| Thickening agent 2 | 1.04 | 9.45 | 4.40 | 4.55 | 2.00 |

| Anti-foaming agent | 1.00 | 0.29 | 0.14 | 0.15 | 0.05 |

| Total | 1.07 | 214.85 | 100.00 | 100.00 | 100.00 |

3M Bubble glass S38

| Raw Material | Density (g/cc) | Weight | Weight (%) | Volume (%) | Dry Volume (%) |

|---|---|---|---|---|---|

| Water | 1.00 | 47.64 | 21.38 | 23.82 | 0.00 |

| Wetting & dispersing agent | 1.16 | 0.87 | 0.39 | 0.37 | 0.23 |

| TiO2 | 4.10 | 61.50 | 27.60 | 7.50 | 15.00 |

| Acrylic resin dispersion | 1.09 | 81.88 | 36.74 | 37.56 | 31.72 |

| 3M Glass Microspheres S22 | 0.38 | 19.00 | 8.53 | 25.00 | 50.00 |

| Thickening agent 1 | 1.05 | 2.21 | 0.99 | 1.05 | 1.00 |

| Thickening agent 2 | 1.04 | 9.45 | 4.24 | 4.55 | 2.00 |

| Anti-foaming agent | 1.00 | 0.29 | 0.13 | 0.15 | 0.05 |

| Total | 1.07 | 222.85 | 100.00 | 100.00 | 100.00 |

Please note: this is just a sample formula, please contact Hitta for expert consultation.

In addition to providing solar energy reflection properties, 3M glass microspheres contribute to reducing the thermal conductivity of the coating due to their hollow structure (insulation capability) with vacuum inside the microspheres.

Effectiveness of Heat-Resistant Paint with 3M Bubble Glass

Depending on the quality of the paint and its composition, the benefits of using 3M glass microspheres to create heat-resistant/insulating/thermal-reflective paint may include:

- Reduction of surface temperature exposed directly to sunlight by 8-25 degrees Celsius. The surface temperature decreases more significantly with more intense sunlight (especially on surfaces directly impacted by west-facing sunlight).

- Increased ability to dissipate heat inside buildings immediately after sunlight fades, thereby significantly reducing cooling energy consumption.

- Superior resistance to dirt and mold, ensuring the paint surface remains durable and vibrant, thereby maintaining long-term heat resistance.

- Helps reduce material expansion and contraction due to continuous temperature changes, thereby increasing the lifespan of structures.

- Good adhesion of paint film, enhancing material durability.

- Easy application: heat-resistant paint can be applied similarly to regular exterior wall paints, using rollers or brushes on the surface to be painted.

Additionally, 3M glass microspheres provide:

- Effective resistance to shrinkage and insulation.

- Reduced resin usage.

- Low dielectric constant.

The superior advantages provided by mixing 3M glass microspheres into paint have expanded its application not only in construction but also in container coatings for maritime vessels. This demonstrates the durability and excellent heat resistance achieved when 3M glass microspheres are added to paint.

Contact us

Hitta JSC is the official distributor of 3M products in Vietnam (certified). As the authorized distributor of 3M in the Vietnamese market, Hitta JSC possesses the capability, expertise, and knowledge of the products and solutions offered by 3M, delivering greater value and maximizing profits for Hitta JSC’s partners and customers. Contact information:

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn

Currently, there are several popular glass microspheres codes for thermal insulation paint in Vietnam, including: K15, S22, and S32,… For further information about the products, please refer to:

Related articles: