Are you pondering over the types of materials to use for soundproofing your car? Join Hitta in exploring the properties, characteristics, and limitations of various soundproofing materials currently available on the market. This will aid you in selecting the most suitable soundproofing materials for your automobile.

The market today offers a plethora of soundproofing materials. How can one choose the optimal soundproofing material for a car, balancing quality, effectiveness, and cost?

Selecting the right soundproofing material not only enhances noise reduction but also shortens the installation time. Furthermore, considering Vietnam’s climatic conditions, issues such as unpleasant odors, adhesive failures, and peeling can arise. Therefore, to accurately choose high-quality, cost-effective soundproofing materials, it is essential to consider the following factors:

Effectiveness of Car Soundproofing Materials

Please contact us for details:

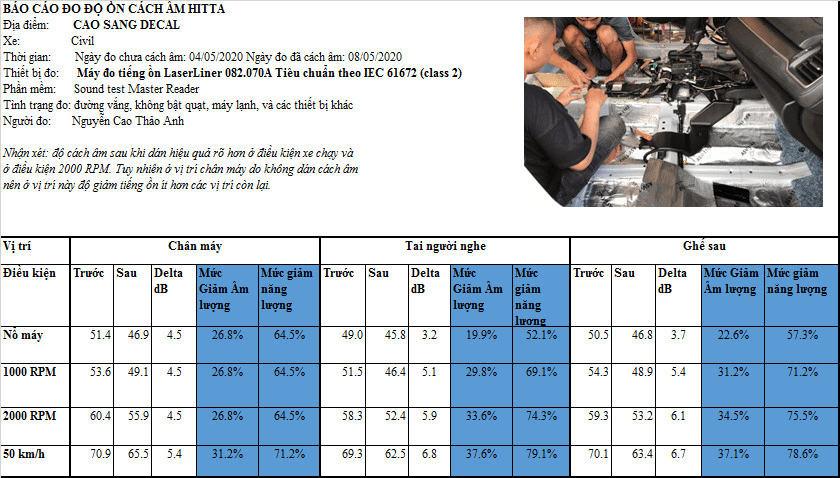

Evaluating the effectiveness of soundproofing goes beyond qualitative assessments and subjective perceptions. Utilizing testing equipment enables a quantitative evaluation. Measurements must be conducted according to standards to accurately determine the noise levels within the vehicle and to assess the effectiveness of the soundproofing treatment.

Read more: Kiểm tra tiếng ồn ô tô

The effectiveness of soundproofing depends on the soundproofing materials, the installation methods, and the skill level of the technician. However, the level of effectiveness also varies due to external factors, such as different car models. The effectiveness can differ between various vehicle models. Additionally, other noise sources, such as engine mount rubber or loose door seals, should also be addressed simultaneously.

Adhesion of Soundproofing Layers to Steel Panels

The better the adhesion of the soundproofing layer, the more effective the soundproofing. Soundproofing materials with adhesive layers made of rubber or bitumen often exhibit poor adhesion and are prone to peeling. Good adhesion ensures that the soundproofing layer firmly contacts the surface, effectively damping sound and vibrations. This is a crucial criterion for selecting soundproofing materials for cars.

Adhesion capability is a key factor in distinguishing the quality of soundproofing. Soundproofing materials that adhere well to the vehicle’s frame are more effective at damping sound and vibrations. High adhesive strength also indicates the durability of the soundproofing. Therefore, choosing the right soundproofing material for your car is essential.

Thermal Durability

Hitta recommends Damping Tape ASV-1102, which is based on Butyl rubber, for its high noise and vibration reduction efficiency, excellent heat resistance, and odor-free properties.

It is not uncommon for certain soundproofing materials with poor heat resistance to become soft and lose their soundproofing properties over time. Thus, selecting a material with good thermal durability is vital. This is particularly important in Vietnam’s climate, where the interior temperature of a parked car can reach up to 150 degrees Celsius. There have been instances where the adhesive layer melts and sticks to the interior after application. Therefore, choosing a heat-resistant material is also an essential aspect of selecting soundproofing materials for cars.

Health Safety

Since soundproofing layers are applied inside the car, it is imperative that they do not emit unpleasant odors and contain no harmful substances. Ensuring the health and comfort of the vehicle’s occupants is a mandatory requirement. The ROHS (Restriction of Hazardous Substances) standard, which is widely adopted, serves as a benchmark for toxic substance safety.

Ease of Installation

Soundproofing materials that are flexible and can conform closely to corners and edges offer better adhesion. Additionally, materials that do not require heating during installation are more convenient choices for practitioners.

Hitta hopes this article helps address your concerns and provides valuable insights.

Overview of Soundproofing Materials

Currently, the market offers a wide variety of soundproofing materials. These can be categorized as follows:

By Form:

- Sheet materials

- Spray materials

By Material Composition:

- Synthetic rubber (such as Butyl rubber)

- Bitumen

Different soundproofing materials have distinct properties and varying degrees of effectiveness. Based on research into the application of Butyl rubber as a soundproofing material, advanced countries are now using Butyl rubber as a premium soundproofing material due to its outstanding properties.

Butyl Rubber:

- Composed of a unique polymer structure that provides excellent sound and vibration dampening.

- Exhibits exceptional adhesion to metal surfaces.

- Highly resistant to high temperatures.

Other Materials:

- Synthetic Rubber: While it provides soundproofing, its heat resistance is low and its adhesion is poor, resulting in less effective soundproofing.

- Bitumen: Known for its origins as a petroleum byproduct, bitumen can emit unpleasant odors over time, posing a significant issue.

This analysis should help clarify the distinctions and advantages of various soundproofing materials for automotive use.