As an elevator manufacturer, we understand that you are seeking ways to optimize your elevator assembly process with the most efficient product solutions while reducing manufacturing costs.

Our priority solution is to provide you with comprehensive elevator assembly solutions to enhance design, productivity, quality, and profitability.

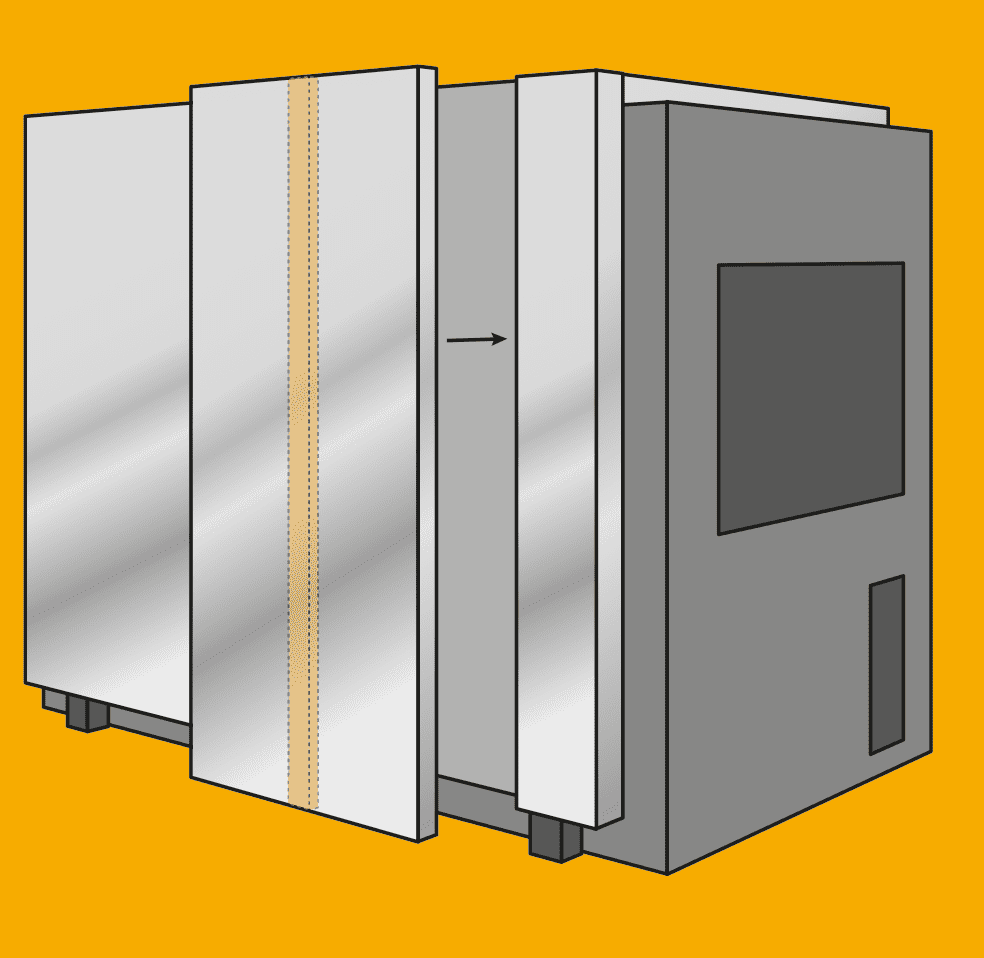

Installing false ceiling in elevators

Hitta’s reinforced Tape solution allows for gap control – the cause of elevator noise when moving up and down.

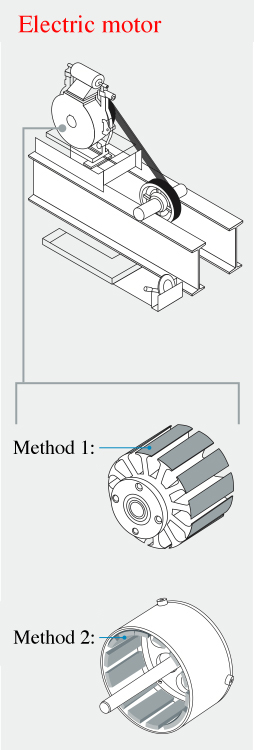

Transmission System

Manufacturing & Assembly

Both geared and gearless drive systems rely on various bonding techniques to ensure safe operation and extended lifespan. Adhesive bonding also plays a crucial role in engine fabrication, reducing assembly time, and improving efficiency.

Hitta provides the best solutions for bonding in engines, meeting the highest safety requirements possible, increasing production output, and reducing costs in elevator assembly, creating fast production lines, and meeting even the most stringent customer demands.

Magnet fixation

General bonding applications are typically characterized by the use of adhesive as the sole means of joining two parts with relatively small gaps between components, typically ranging from 0.05 mm to 2.5 mm. Adhesives and tapes provide the best solution for assembling engines, meeting the highest requirements while allowing process automation and reducing overall costs.

Comparison with traditional methods

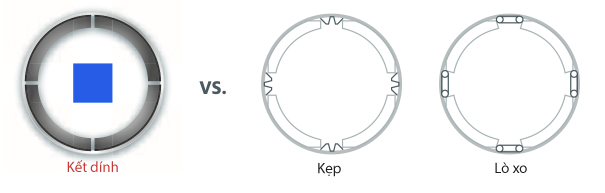

Bonding vs clamps and springs

Benefits for customers

- Increase productivity by using fast-curing products.

- Feasibility of ultra-fast automated production lines.

- Prevent magnet damage (no cracking, no corrosion).

- Meet the most stringent customer requirements (e.g., durability, shock resistance, heat resistance).

- Prevent noise, vibration for improved engine performance.

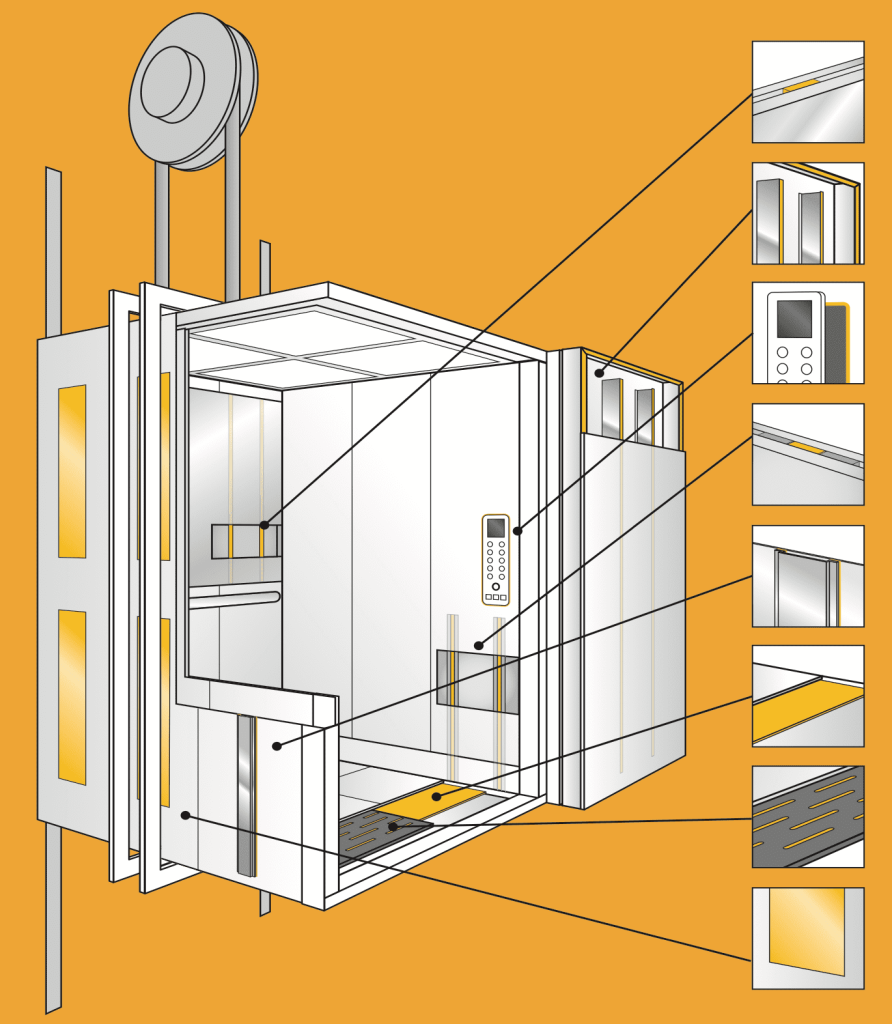

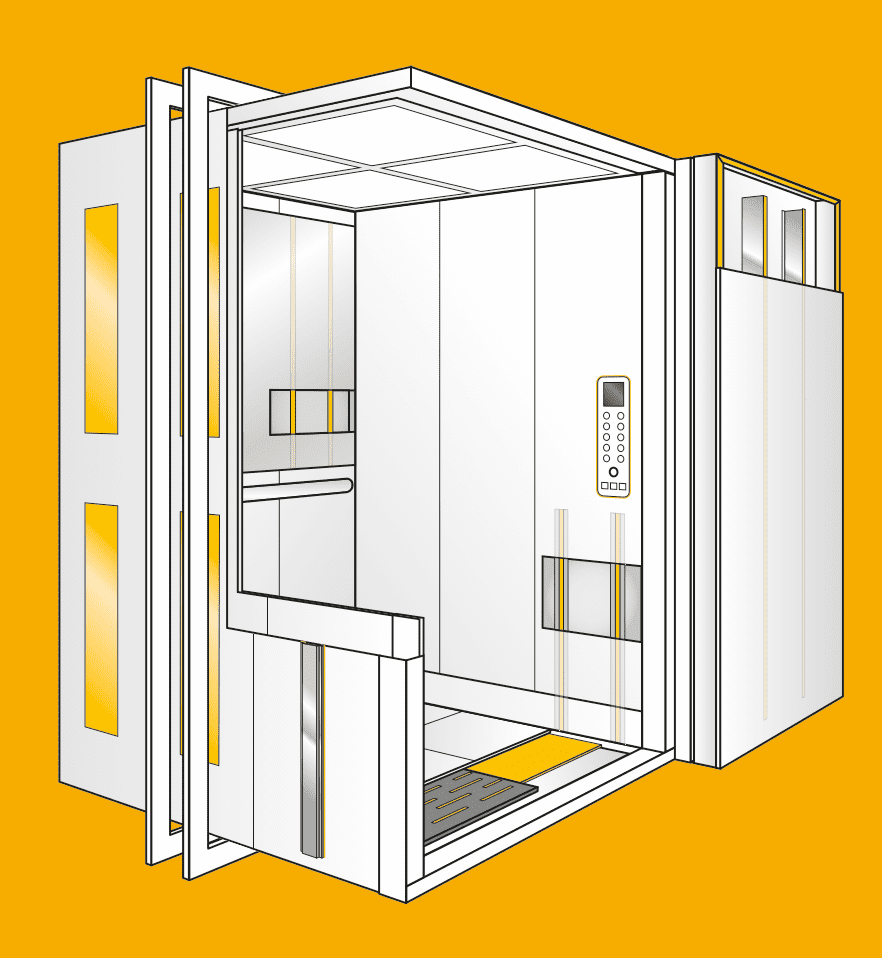

Cabin & door

Assembly & Finishing

The metal panels used in the production of elevator cabins & entrance doors have different structures. Hitta’s adhesive solution helps elevator manufacturers reduce the weight of wall panels, improve elevator performance (increased durability, reduced noise), and achieve significant cost savings in manufacturing and installing components.

- “Elevator cabins & floor doors.

- Wall panels.

- Interior cladding.

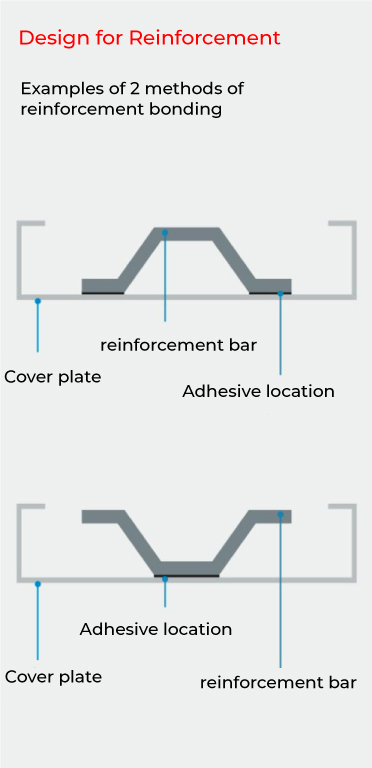

When manufacturing door panels & cabins, the strong bonding of stiffeners/bracing bars brings significant advantages over traditional assembly methods. Additionally, adhesive solutions for door cladding and cabin interior applications allow customers to minimize manufacturing time while increasing construction accuracy.

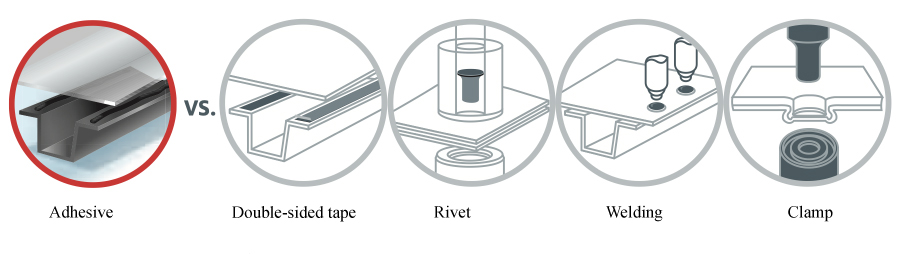

Comparison with traditional methods:

Customer Benefits

- Construction at room temperature, one-step process.

- Quick fixation while allowing for adjustments during assembly.

- Flexible and compatible with most finishing layers.

- Aesthetic solution, reducing errors while maintaining the flatness of wall panels & cladding.

- Improved corrosion resistance.

- Bonding and sealing of joints simultaneously.

- Soundproofing & fire resistance.

Contact us

- ☎️ Hotline: 0565 33 68 79

- ✉️ Email: hittajsc@hitta.vn

Related solutions: