Reinforced tape is a strong bonding solution designed to connect various surfaces, components, and materials with high adhesion, serving as a replacement for rivets, screws, bolts, welding, and more.

Reinforced tape opens up a new world of possibilities for structural bonding, connecting different materials and surfaces to replace rivets, screws, bolts, and welding, while also enhancing structural design, aesthetics, construction productivity, durability, and overall reliability of product connections. Additionally, reinforced tape, as its name suggests, has the ability to reinforce, strengthen, dampen vibrations, and stabilize materials effectively.

Uses of reinforced tape

For decades, we’ve relied almost exclusively on methods like screws, rivets, bolts, welding, etc., with many drawbacks including:

Mechanical screws, bolts, and nuts add significant weight.

Rivets penetrate materials unevenly, creating stress points prone to damage.

Welding is time-consuming and interrupts assembly processes.

Liquid and spray adhesives are not always optimal, requiring time and complexity.

Reinforced tape serves as a replacement for all adhesive, connection, bonding, and welding methods, often more efficiently than traditional screws, bolts, rivets, or welding. With extremely high adhesion, excellent reinforcement capabilities, reinforced tape offers a versatile solution for various applications.

- Tại sao nên sử dụng băng keo cường lực?

- Tại sao nên sử dụng băng keo cường lực BowTape?

- Tìm hiểu về keo PSA

Reinforced tape advantages

Reinforced tape is revolutionizing the way we bond and connect everything. Here are some outstanding advantages:

- Ultra-lightweight: Reinforced tape with Acrylic foam adhesive is extremely lightweight, available in various thicknesses and widths to suit different materials during installation.

- High performance: Over 10 times stronger than rivets, reinforced tape surpasses traditional bonding solutions, ensuring uniform bonding across surfaces.

- No visible traces: Many bonding solutions create uneven surfaces, compromising aesthetics. Reinforced tape leaves no visible traces, making connections nearly invisible.

- Safe to use: Reinforced tape is extremely safe, requiring no additional harsh chemicals for support.

- Quick installation: Reinforced tape is applied and installed just like regular tape, simplifying the process. This significantly reduces installation time.

- Flexibility: The structure of reinforced tape allows for easy application on any surface, with customizable shapes and sizes. Installers can easily cut the tape to desired shapes.

Additionally, here are some other noteworthy advantages:

- Long-lasting: Reinforced tape is designed and engineered for long-term durability, ensuring no loosening or weakening over time in bonded areas.

- High durability: With resistance to heat, UV light, moisture, and solvents, reinforced tape withstands harsh environmental conditions, reducing metal and material corrosion.

- Non-corrosive: Unlike traditional methods like screws and mechanical welds, reinforced tape does not corrode over time, eliminating the need for maintenance.

- Time-saving: Installation of reinforced tape is simple, following proper procedures and thorough surface cleaning, with no need for additional materials or methods. Therefore, reinforced tape is widely used in assembly processes, saving both time and money.

- Cost-effective: Considering the aforementioned advantages, reinforced tape serves as an all-in-one solution for bonding, connecting, welding, and fastening, without the need for additional complex methods. This optimizes costs effectively.

Reinforced tape also provides users with a distinct bonding advantage through its seamless integration with various surfaces and materials.

Reinforced tape can be applied to various materials

- Tiles, concrete, wood.

- Composite materials.

- Foam and glass fibers.

- Glass and ceramics.

- Metal.

- Painted surfaces.

- Plastic and flexible vinyl.

- Rubber.

Environments where strong adhesive tape can be used

The durability and flexibility of strong adhesive tape are remarkable. You can use the tape indoors and outdoors, and in various environmental conditions:

- Chemicals: withstands common solvents (acetone, ammonia, isopropyl alcohol, oils, etc.).

- Moisture: operates in high humidity environments.

- Wet conditions: resists both fresh and saltwater, even when submerged.

- Temperature: functions in environments from -40°C to 100°C.

- UV light: protects against natural and artificial ultraviolet rays.

Applications of strong adhesive tape

Due to its excellent properties, strong adhesive tape is widely used in many industries.

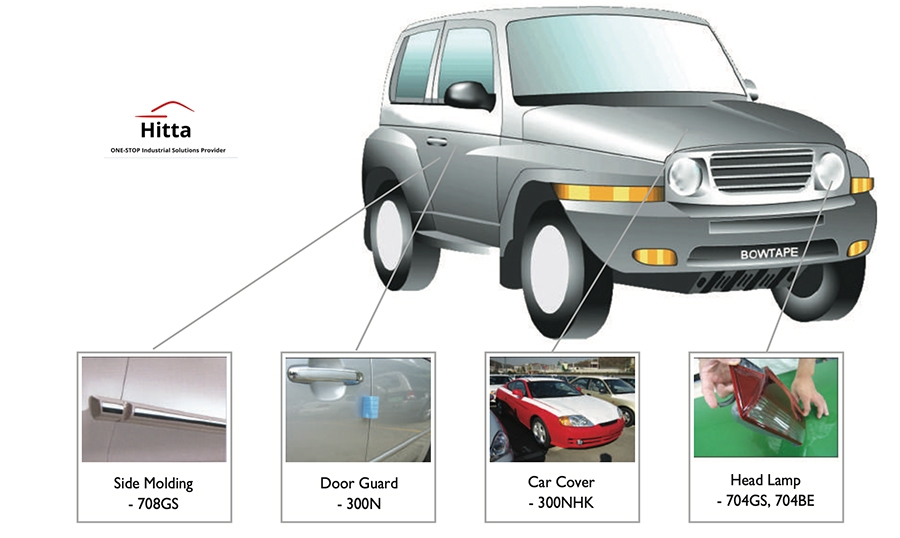

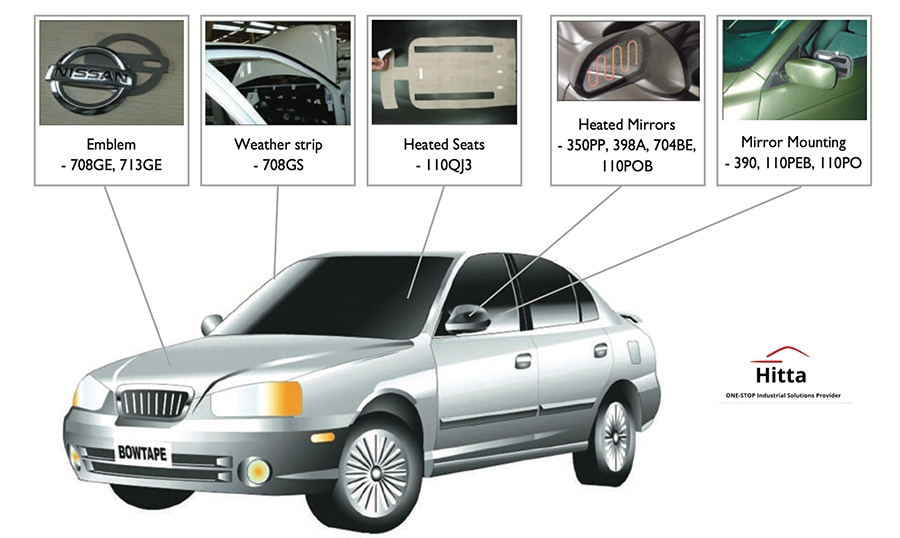

Automotive & Transportation Industry

Tough adhesive tape is widely used in the automotive industry because its adhesive system provides sensitive bonding with high pressure (PSA or pressure sensitive adhesive). The solid core of the tough adhesive tape provides extremely high bonding strength while maintaining enough flexibility to withstand various rates of expansion and contraction.

Different types of tough adhesive tape offer different bonding solutions and can bond plastic to metal, glass to metal, or metal to metal. Applications in vehicles include attaching and bonding interior and exterior decorations and attaching automotive components. In addition to providing an accurate and clean bonding system, tough adhesive tape absorbs vibrations and helps improve fuel efficiency and reduce weight, thus enhancing assembly and manufacturing processes.

Electronics

The rapid development in the electronics industry, including increasingly compact and lightweight systems, has been greatly supported by the advancement of tough adhesive tape technology.

The manufacturing process is simplified, and product designers have more creative freedom due to the many benefits of using tough adhesive tape compared to cumbersome traditional fixed methods.

Televisions, smartphones, tablets, etc., all benefit from using tough adhesive tape. With the ability to create tight bonds, ensuring prevention of water and dust infiltration into electronic devices, and using tough adhesive tape to attach metal and plastic components, eliminating the need for additional large parts to cover bulky fasteners, it helps maximize aesthetic appeal.

Signage

Mechanical screws are often used to hold signs together, but they are prone to rust and damage in harsh conditions. High-performance adhesive tapes provide cost-effective and quick installation solutions for the signage industry by eliminating the need for labor-intensive activities like drilling and hole punching. With fewer structural weak points and evenly distributed stress from the adhesive layer, tough adhesive tape offers a stronger and more reliable bond than any other solution.

Tough adhesive tape can be used both indoors and outdoors due to its UV resistance, ensuring longevity without the need for repair or replacement.

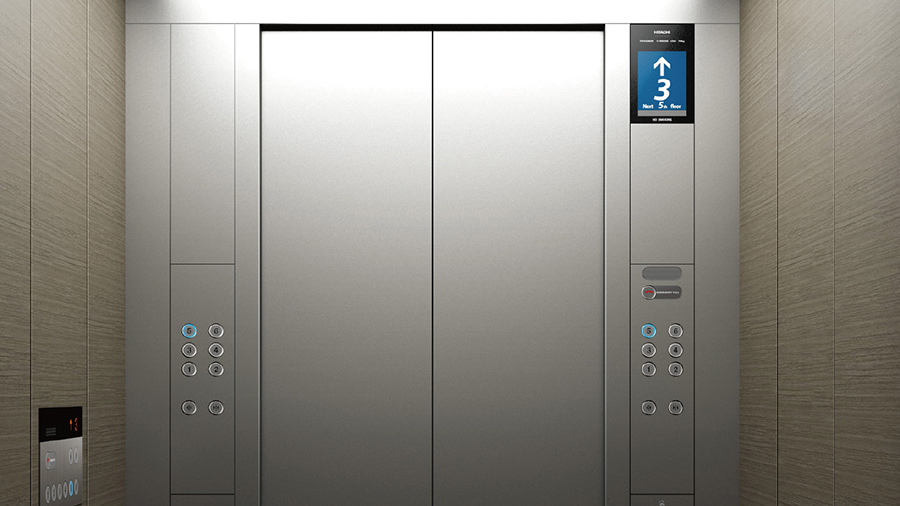

Elevators

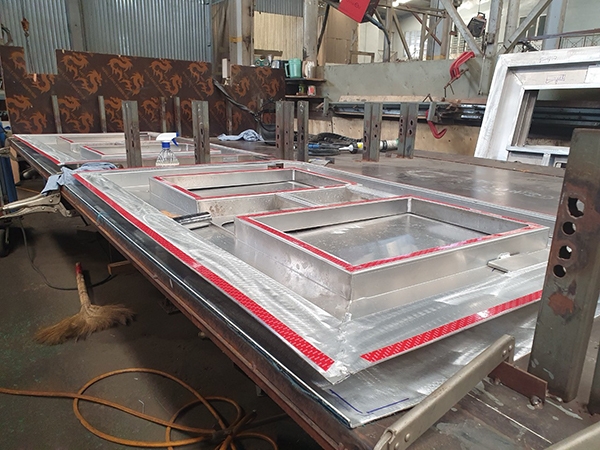

With its reinforcement, vibration resistance, toughness, high bonding strength, and durability over time, tough adhesive tape is applied to attach stiffening bars for elevator doors, control panels, and iron frames in elevator ceilings. Learn more about this solution:

Checking the durability of tough adhesive tape

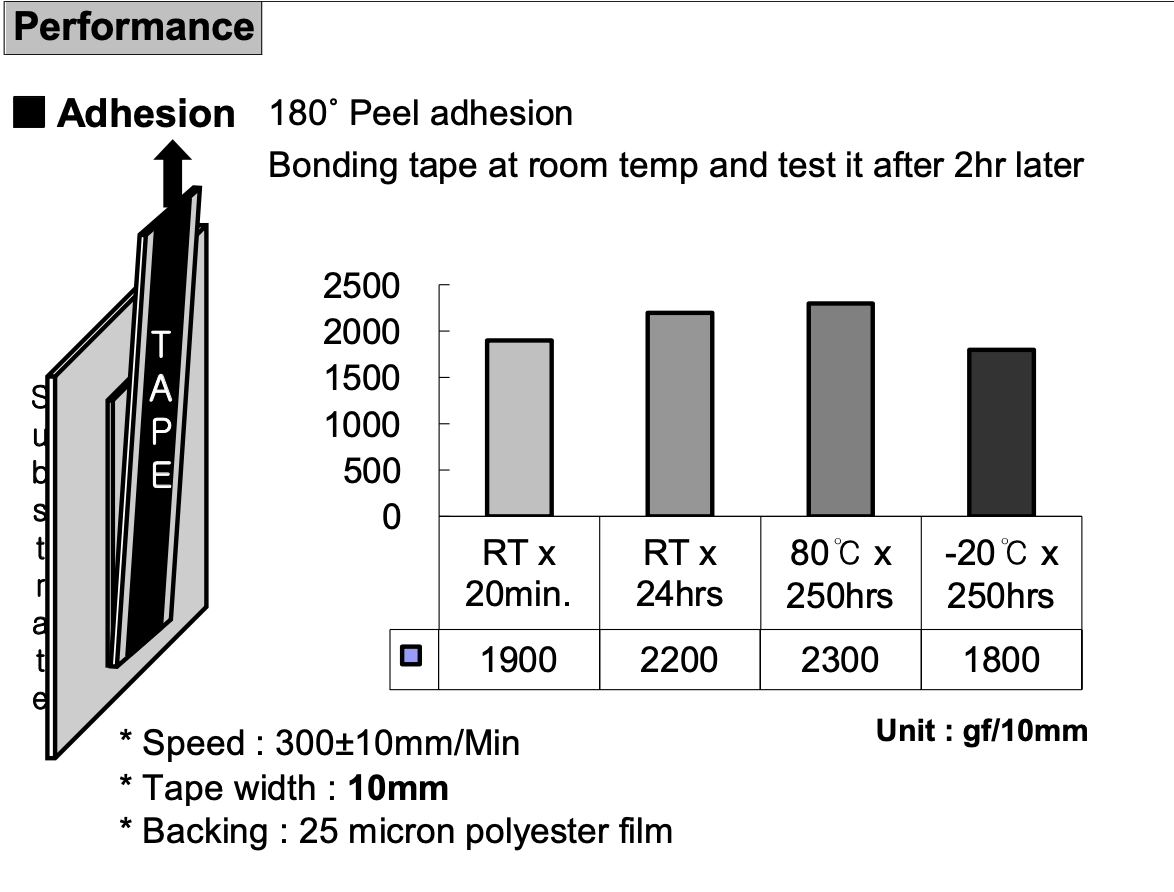

Adhesion Test

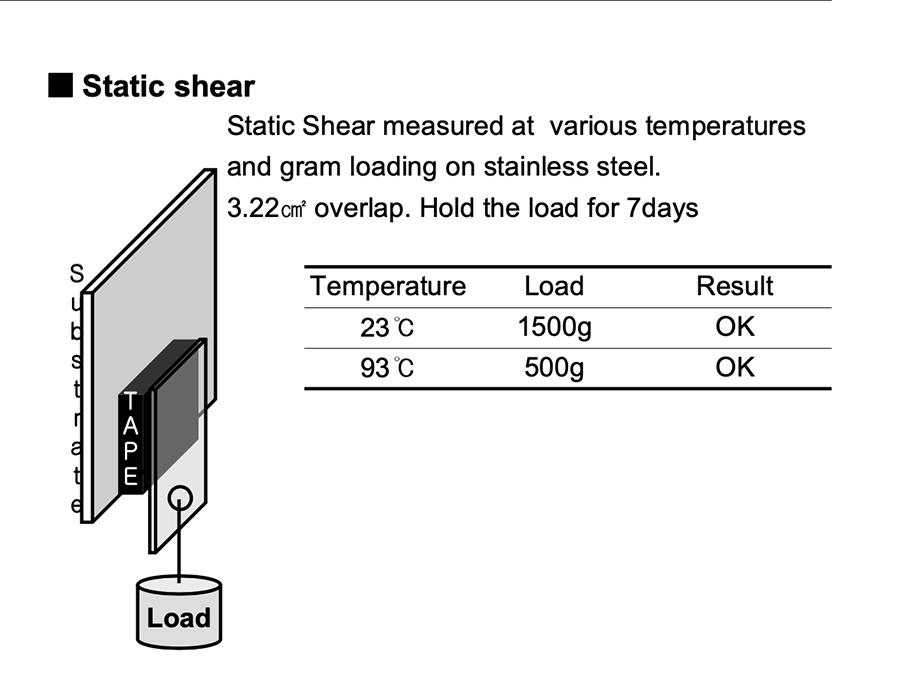

Load Test

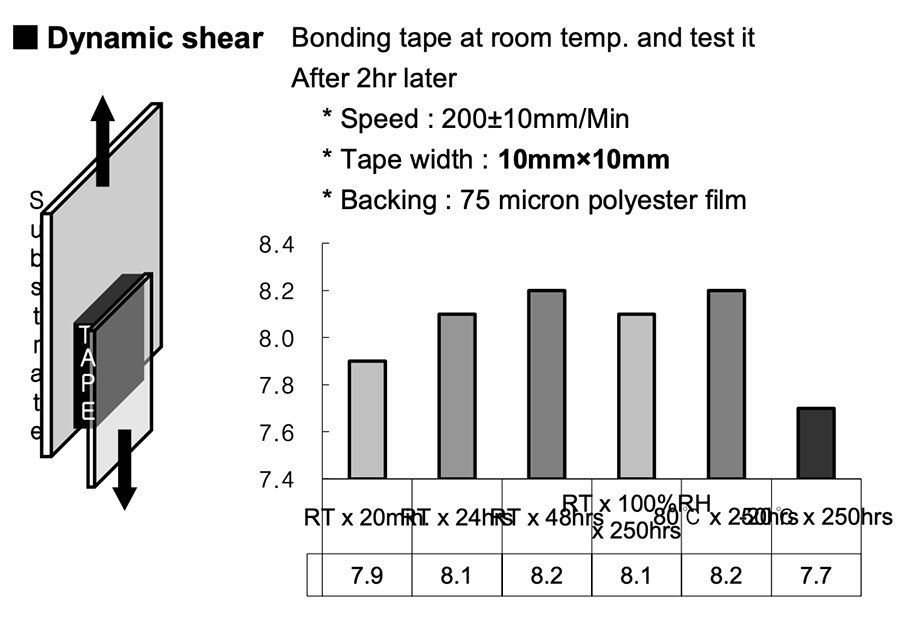

Tensile Strength Test

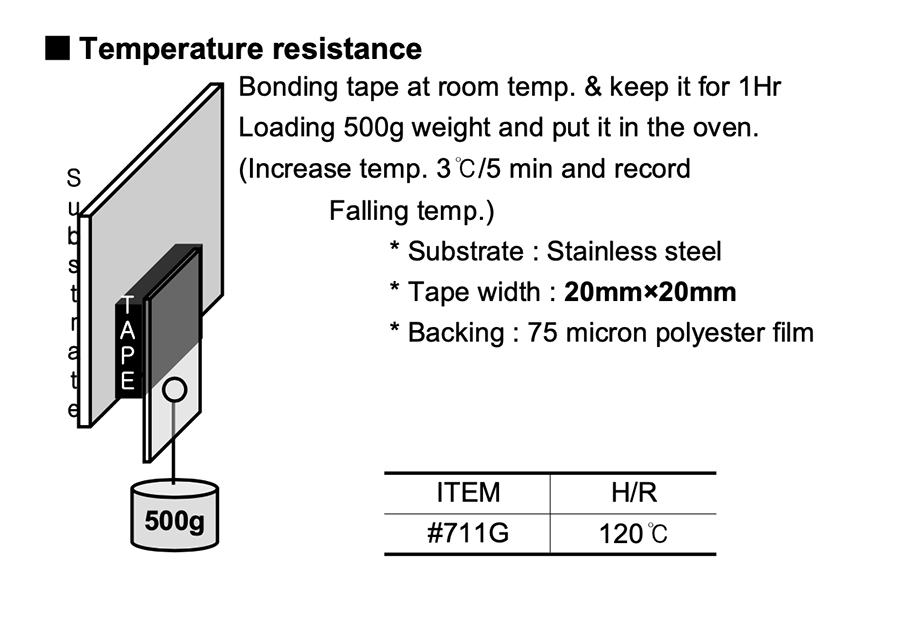

Heat Endurance Test

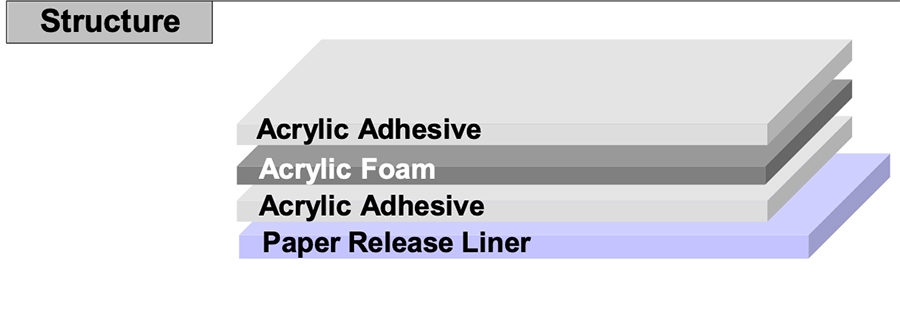

Cấu tạo của băng keo cường lực

Cấu tạo của băng keo cường lực có cấu trúc như hình gồm:

- Keo Acrylic.

- Acrylic Foam (bọt Acrylic).

- Keo Acrylic.

- Paper Release Liner (lớp giấy định hình).

Cấu tạo này cho phép tối đa hoá độ kết dính, dễ thi công và an toàn cho người sử dụng.

Reinforced tape products:

-

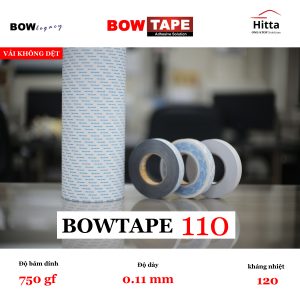

Bow Tape 110 (0.11 mm)

Bow Tape 110 (0.11 mm) -

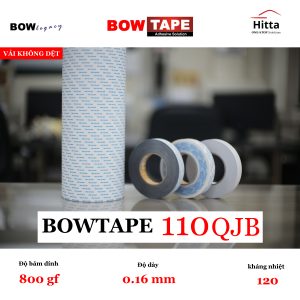

Bow Tape 110QJB (0.16 mm)

Bow Tape 110QJB (0.16 mm) -

Acrylic Foam Tape Bow Tape 723G (2.3 mm)

Acrylic Foam Tape Bow Tape 723G (2.3 mm) -

Acrylic Foam Tape Bow Tape 730W (3.0 mm)

Acrylic Foam Tape Bow Tape 730W (3.0 mm) -

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm)

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm) -

Bow Tape PE foam Tape 398A (0.8 mm)

Bow Tape PE foam Tape 398A (0.8 mm) -

Bow Tape PE foam tape 398EW (1.0 mm)

Bow Tape PE foam tape 398EW (1.0 mm) -

Bow Tape 391W (1.6 mm)

Bow Tape 391W (1.6 mm) -

Bow Tape 300NHK

Bow Tape 300NHK -

Acrylic Foam Tape – Bow Tape 711BH

Acrylic Foam Tape – Bow Tape 711BH -

Acrylic Foam Tape – Bow Tape 715B (1.5 mm)

Acrylic Foam Tape – Bow Tape 715B (1.5 mm) -

Bow Tape 3510PP (0.1 mm)

Bow Tape 3510PP (0.1 mm) -

Bow Tape 550 (0.17 mm)

Bow Tape 550 (0.17 mm) -

Acrylic Foam Tape – Bow Tape 7025THH

Acrylic Foam Tape – Bow Tape 7025THH -

Bow Tape 1750L (0.05 mm)

Bow Tape 1750L (0.05 mm) -

Bow Tape 590 (0.09 mm)

Bow Tape 590 (0.09 mm) -

Bow Tape 710SF (1.0 mm)

Bow Tape 710SF (1.0 mm) -

Bow Tape 3510B

Bow Tape 3510B -

Bow Tape 3505B

Bow Tape 3505B -

Bow Tape 716GS

Bow Tape 716GS -

Bow Tape 706BH (0. 6mm)

Bow Tape 706BH (0. 6mm) -

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive -

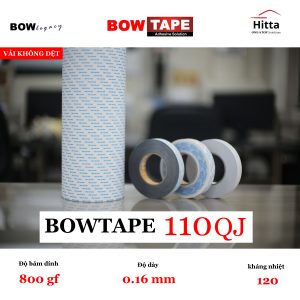

Bow Tape 110QJ (0.16 mm)

Bow Tape 110QJ (0.16 mm) -

Bow Tape 704WE (0.4 mm)

Bow Tape 704WE (0.4 mm) -

Bow Tape 706BH (0.6 mm)

Bow Tape 706BH (0.6 mm) -

Bow Tape 708GSX (0.8 mm)

Bow Tape 708GSX (0.8 mm) -

Acrylic Foam Tape Bow Tape 711G (1.1mm)

Acrylic Foam Tape Bow Tape 711G (1.1mm)

Hitta JSC is the brand representative and exclusive distributor of Bow Tape in Vietnam. Contact us for the best support!

About Hitta

As the official exclusive distributor of BowTape tough adhesive tape in the Vietnamese market, Hitta JSC has the capability, expertise, and knowledge about BowTape products and solutions being distributed, providing more value and maximizing profits for Hitta JSC’s partners and customers. Contact information:

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn

Here are some real-life installation photos from Hitta’s partners: