The signage and advertising industry benefits from the convenience and simplicity of tape compared to traditional liquid adhesives. Super adhesive or industrial strength tape is easy to apply and can provide permanent or removable bonding (temporarily with strong adhesion) depending on the product requirements. Super adhesive tape is also ideal for cases where nails, ties, and other traditional mechanical connection methods may cause signage to warp or bend.

Signage & Advertising Display Industry

Over many decades, the signage and advertising display industry has seen significant developments in patterns and designs, putting pressure on finding solutions to connect various components, surfaces, shapes, and materials securely without compromising the product design.

Outdoor advertising displays pose a significant challenge due to the weather’s impact on the durability of product joints, making traditional mechanical solutions less effective over time.

The benefits of super adhesive tape for the signage industry are extremely pronounced. Tape provides quick adhesion, easy application, clean bonding, adheres to various surfaces, and eliminates many common issues caused by mechanical screws. Some typical applications of super adhesive tape in the signage and advertising display industry include:

- Road traffic signs.

- Attaching A-frame advertising signs.

- Securing LED light strips.

- Affixing individual signs, letters on signage.

- Attaching polycarbonate sheets for illuminated signs.

- Large signage.

- Mounting shells and lights on emergency signs.

- Attaching box signs to frames.

- Framing for digital signage.

- Mounting LED matrix signs.

- Attaching nameplates.

- And so on.

In some cases, advertising signage may have extremely high durability requirements and need to withstand environmental factors such as strong winds on high-rise buildings. Super adhesive tape, with its high bonding strength and long-term durability, is ideal for such demanding applications mentioned above.

Concerns about metal fatigue due to vibrations (from wind, impacts, etc.) leading to weakened joints, welds in traditional solutions will be completely eliminated when transitioning to using super adhesive tape solutions.

Acrylic foam tape can withstand surface expansion and contraction better without showing signs of warping or distortion while maintaining high adhesive properties.

Lighted advertising signs pose a challenge for adhesives because LED lights are affected by UV rays, which can damage most adhesives. Transparent acrylic foam tape is UV resistant without degradation or discoloration, making it ideal for attaching and securing illuminated signs.

The benefits of super adhesive tape for the industry include

- Quick installation, easy implementation in automated production lines.

- No need for labor training, saving labor costs.

- Material cost savings as tape installation does not require any special equipment or specialized tools.

- Tape can be cut into small segments with customizable lengths and widths, easily adhering to the complex designs of any product or advertising sign.

- The bonding of industrial strength tape is non-conductive, does not suffer from metal fatigue, and remains durable over time.

- The appearance of tape bonding is clean, without excess points, protrusions, or indentations.

- Tape bonding can be used for sealing, ensuring no water or dust penetrates inside.

- Resilient to heat, vibration, and impact better than other solutions.

- Can adhere to various types of material surfaces required by the advertising industry: aluminum, steel, plastic, polycarbonate, etc.

The durability of Bowtape industrial strength tape

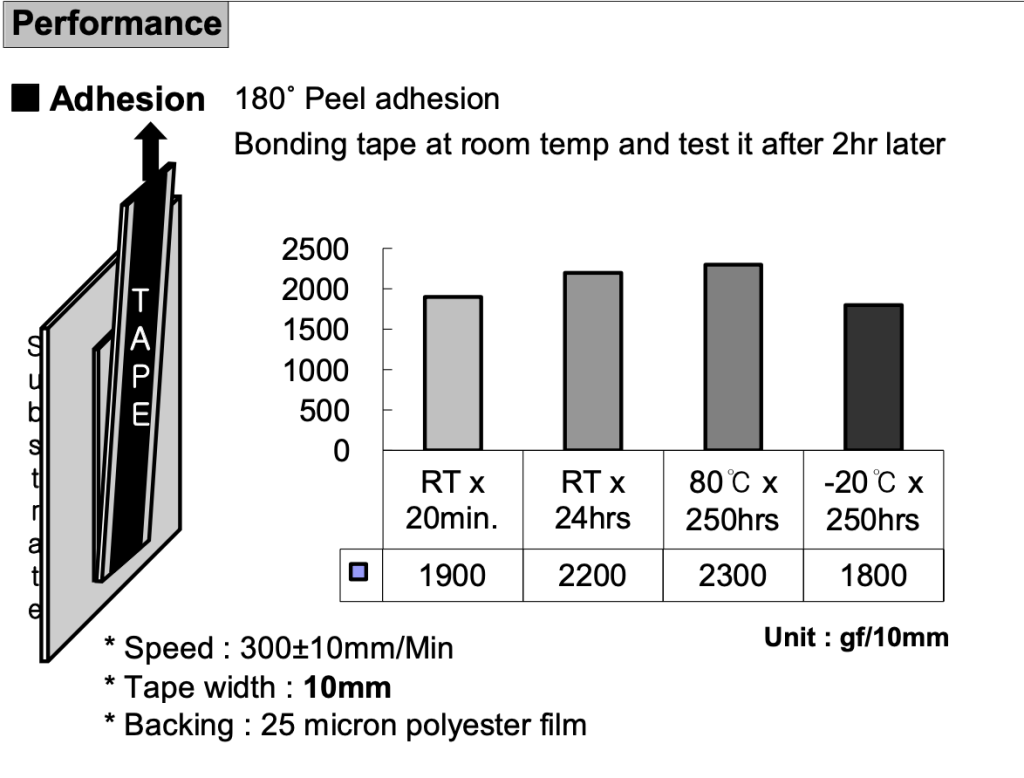

Adhesion strength testing

The test is as described in the figure:

- The peel angle is 180 degrees.

- The industrial strength tape is pulled for over 2 hours at room temperature.

- Result: good adhesion, minimal displacement, passing the test.

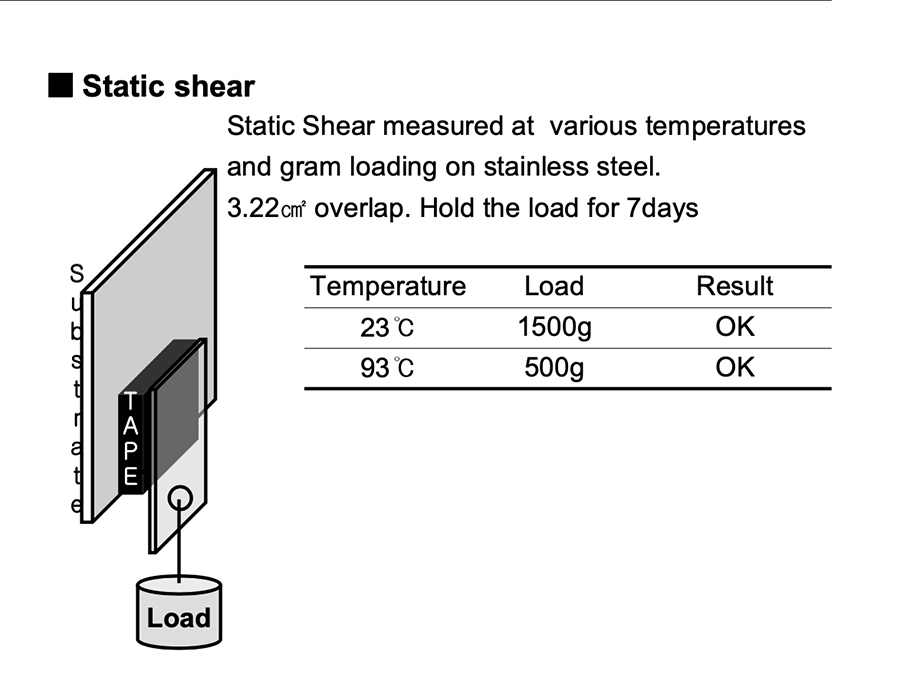

Gravity load testing

The test is as described in the figure:

- Enduring load for 7 days at different temperatures.

- Load 1: 1500g at 23°C.

- Load 2: 500g at 93°C.

- Result: good adhesion, passing the test.

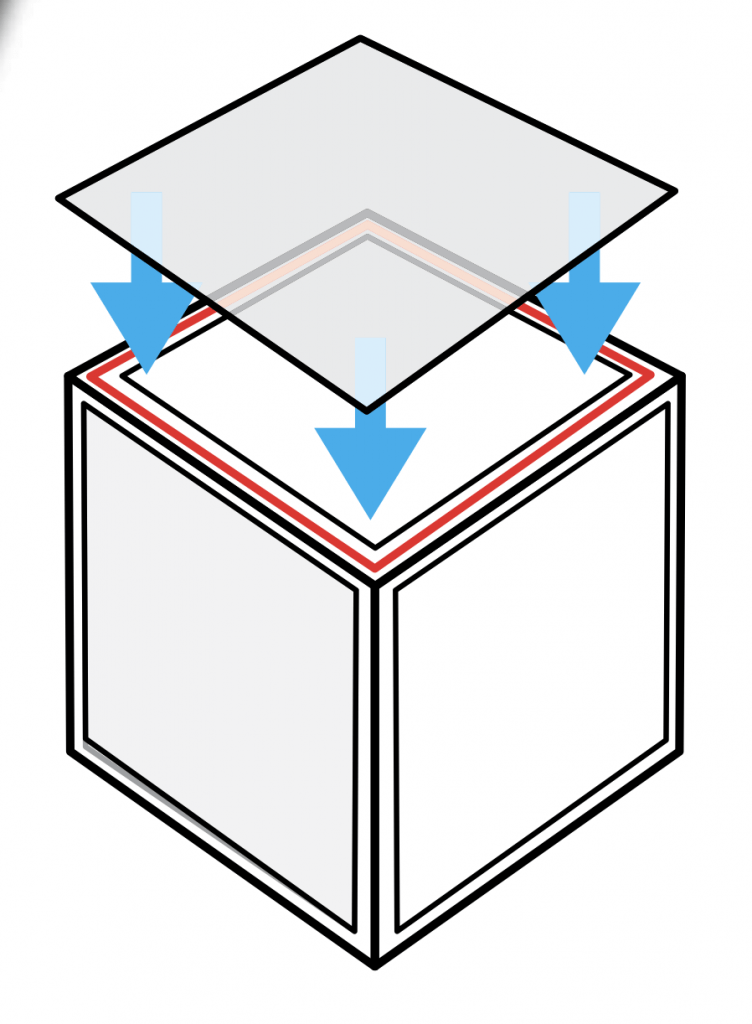

Tensile strength test in both directions

The test is as described in the figure:

- Enduring tension from both sides (top and bottom) at room temperature for over 2 hours.

- Result: good adhesion, minimal displacement, passing the test

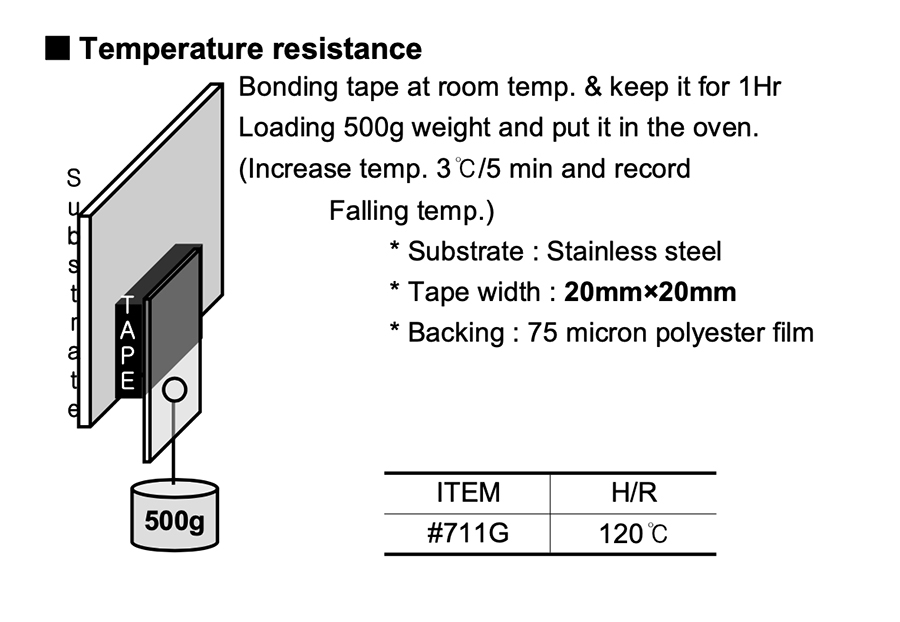

Temperature increasing durability test

The test is as described in the figure:

- Enduring a load of 500g at room temperature for one hour & gradually increasing the temperature.

- Every 5 minutes, the temperature increases by 3°C.

- Result: good adhesion, minimal displacement, passing the test.

Contact us

Hitta specializes in supplying double-sided acrylic adhesive tapes as well as various specialized tapes for both industrial and commercial sectors. Contact us for advice on the most effective solutions at the lowest cost.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn

Products:

-

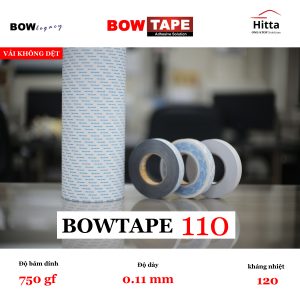

Bow Tape 110 (0.11 mm)

Bow Tape 110 (0.11 mm) -

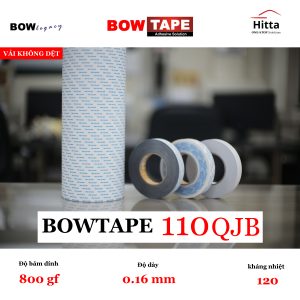

Bow Tape 110QJB (0.16 mm)

Bow Tape 110QJB (0.16 mm) -

Acrylic Foam Tape Bow Tape 723G (2.3 mm)

Acrylic Foam Tape Bow Tape 723G (2.3 mm) -

Acrylic Foam Tape Bow Tape 730W (3.0 mm)

Acrylic Foam Tape Bow Tape 730W (3.0 mm) -

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm)

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm) -

Bow Tape PE foam Tape 398A (0.8 mm)

Bow Tape PE foam Tape 398A (0.8 mm) -

Bow Tape PE foam tape 398EW (1.0 mm)

Bow Tape PE foam tape 398EW (1.0 mm) -

Bow Tape 391W (1.6 mm)

Bow Tape 391W (1.6 mm) -

Bow Tape 300NHK

Bow Tape 300NHK -

Acrylic Foam Tape – Bow Tape 711BH

Acrylic Foam Tape – Bow Tape 711BH -

Acrylic Foam Tape – Bow Tape 715B (1.5 mm)

Acrylic Foam Tape – Bow Tape 715B (1.5 mm) -

Bow Tape 3510PP (0.1 mm)

Bow Tape 3510PP (0.1 mm) -

Bow Tape 550 (0.17 mm)

Bow Tape 550 (0.17 mm) -

Acrylic Foam Tape – Bow Tape 7025THH

Acrylic Foam Tape – Bow Tape 7025THH -

Bow Tape 1750L (0.05 mm)

Bow Tape 1750L (0.05 mm) -

Bow Tape 590 (0.09 mm)

Bow Tape 590 (0.09 mm) -

Bow Tape 710SF (1.0 mm)

Bow Tape 710SF (1.0 mm) -

Bow Tape 3510B

Bow Tape 3510B -

Bow Tape 3505B

Bow Tape 3505B -

Bow Tape 716GS

Bow Tape 716GS -

Bow Tape 706BH (0. 6mm)

Bow Tape 706BH (0. 6mm) -

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive -

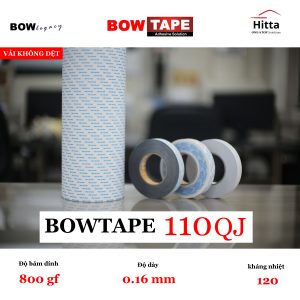

Bow Tape 110QJ (0.16 mm)

Bow Tape 110QJ (0.16 mm) -

Bow Tape 704WE (0.4 mm)

Bow Tape 704WE (0.4 mm) -

Bow Tape 706BH (0.6 mm)

Bow Tape 706BH (0.6 mm) -

Bow Tape 708GSX (0.8 mm)

Bow Tape 708GSX (0.8 mm) -

Acrylic Foam Tape Bow Tape 711G (1.1mm)

Acrylic Foam Tape Bow Tape 711G (1.1mm)