Double-sided tape can create a super-strong, aesthetically pleasing bond for most materials and is applied in virtually every industry.

Instead of bulky liquid adhesives or cumbersome tying, screws, bolts & surface-destructive welding, the thin bond that double-sided tape provides gives you design freedom, offering flexibility in production. Double-sided tape belongs to PSA (Pressure Sensitive Adhesive), which boasts high initial tack, strong adhesion, and can be used from indoor to harsh outdoor environments. Despite its thin bond, it brings flexibility with high performance for most conditions. So what makes double-sided tape so multifunctional?

What is Double-Sided Tape?

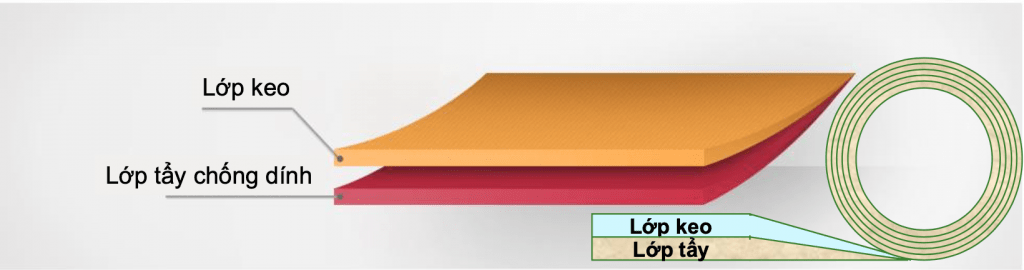

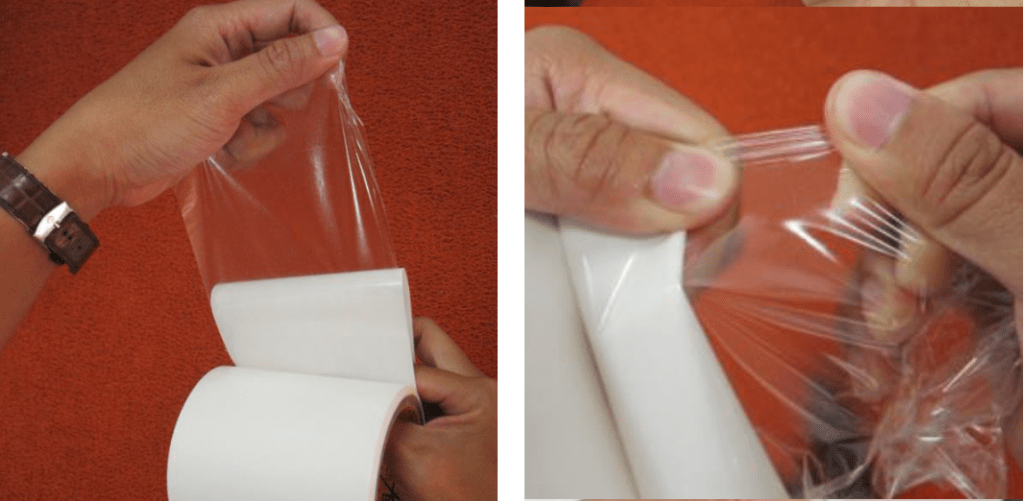

Created by applying a thin layer of adhesive on each side of the backing material, double-sided tape, also known as double-coated tape, is widely used across many industries for applications such as bonding, holding, mounting, joining, and packaging. Clearly, double-sided tape is used to bond two surfaces together in assembly processes and often leaves no visible adhesive seam in the finished product. This is because double-sided tape is placed in between & is very thin, making the joint virtually invisible. This outstanding advantage allows for a neater appearance and better manual handling skills.

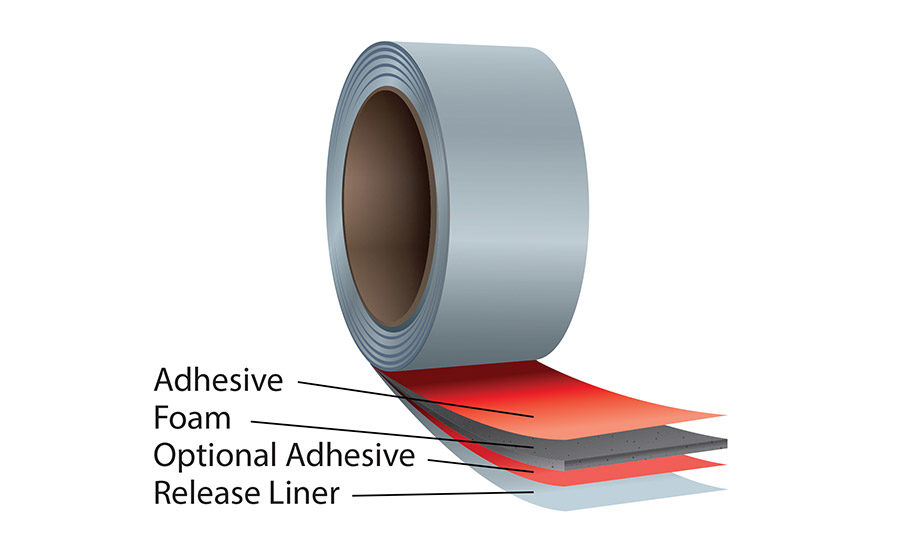

Double-sided tape can be thin (such as paper type) or thick (such as foam type), coated with rubber, acrylic, or their modified versions to have different properties. Double-sided tape has the ability to bond well with surfaces that are often uneven, non-uniform, or have various patterns and structures.

How does double-sided tape achieve these capabilities?

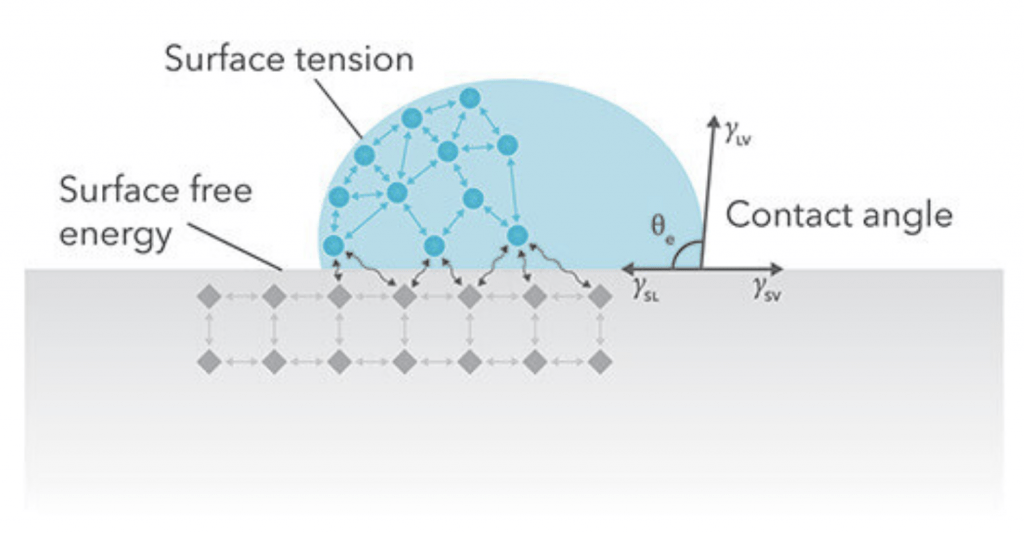

Surface Energy

To understand how double-sided tape can adhere, we need to explore two technical terms:

- Low Surface Energy (LSE)

- High Surface Energy (HSE)

Surface energy, including both low and high surface energy of materials, is crucial for the adhesion of any type of tape.

Adhesion is determined by the molecular attraction force between materials. The strength of this attraction depends on the surface energy of the material.

- High surface energy = strong molecular attraction force.

- Low surface energy = weak molecular attraction force.

Microscopic features create significant differences, and adhesive materials (like tape) need to be selected to match specific surfaces/materials.

- Materials with high surface energy: metals, glass, nylon, polyester, epoxy paint, rigid PVC.

- Materials with low surface energy: coatings, synthetic materials, acetal, polystyrene, PVA, polyethylene, polypropylene, and other plastics.

Benefits of Using Double-Sided Tape

Quick Installation Time

Double-sided tape can be easily applied by hand or through automation, eliminating the need to wait for adhesive to dry. Some components can be pre-applied with double-sided tape and then adhered to the remaining part afterward, speeding up the overall construction and assembly process.

Flexible Design

With its versatility, ability to fill gaps, and invisible bonding lines, double-sided tape provides you with flexible design options you need. It also offers flexibility in the manufacturing process by allowing parts to be pre-taped and then set aside for the next steps.

Bonding Different Materials with Low Surface Energy

Lightweight designs often require bonding different materials using different adhesives on each side of the tape. Double-sided tape can bond with Low Surface Energy (LSE) materials such as certain types of plastics and paints.

Immediate Effectiveness

Double-sided tape provides instant adhesion without the need for waiting time, allowing assembled parts to immediately move on to the next stage of production.

High Aesthetic Value

Double-sided tape provides virtually invisible bonding lines without any protruding residue. It also enhances product sleekness by eliminating mechanical fasteners like ties and screws, allowing for the use of thinner, lighter materials by evenly distributing stress on the bond.

Moisture Resistance

Even the thinnest type of double-sided tape provides adhesion to both materials across the entire bonding area, thus helping prevent moisture from seeping through the bond line.

Applications of Double-Sided Tape

Functional Applications:

- Bonding metals and high-temperature resistant materials.

- Surfaces with high surface energy.

- Foam and fabric.

- Surfaces with low surface energy.

- High-temperature and chemical-resistant bonding.

- Quick adhesion and bonding to low surface energy surfaces.

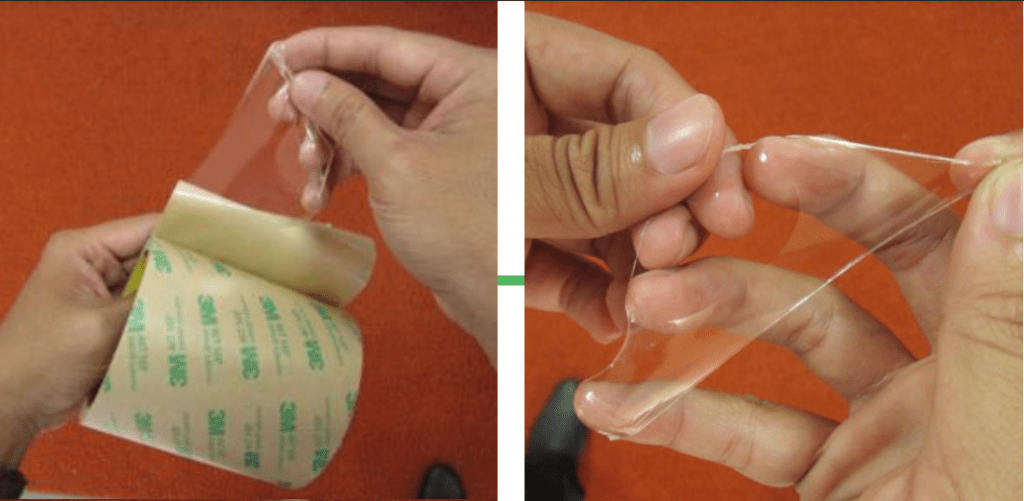

Video demonstration of adhesive strength replacing mechanical screws

Industry-Specific Applications

Did you know that in the automotive manufacturing industry, double-sided tape has replaced rivets and ties for many years and is used to attach everything from dashboards to specialized equipment on vehicles? Here are some other applications of double-sided tape:

- Attaching metal logos.

- Use for transparent materials.

- Bonding tempered glass edges.

- Attaching digital screens.

- Signboard design.

- Bonding metal sheets and stiffeners.

- Attaching metal sheets to frames

- .And many more applications.

- Băng keo cường lực cho thang máy

- Giải pháp băng keo cường lực

- Tại sao nên sử dụng băng keo cường lực?

Advantages of Double-Sided Tape

The advantages of double-sided tape include:

- Quick adhesion capability.

- Uniform thickness of the bond.

- Odorless, hence no need for ventilation systems.

- No drying or curing process required.

- No chemical reaction during bonding.

- Elasticity of the bond.

- Vibration reduction capability.

- Even distribution of impact force on the bond.

- Ability to prevent water, air, and dust.

- Bonding of different material surfaces.

- Insulation capability.

- Various tools available for automation of the bonding process

The benefits of double-sided tape include:

- Bonding of different material surfaces.

- Bonding of materials with low surface energy.

- Water, air, and dust prevention.

- Vibration and noise reduction.

- Brand recognition.

- Reduction in the weight of the bond.

- No surface damage during bonding.

Types of Double-Sided Tape

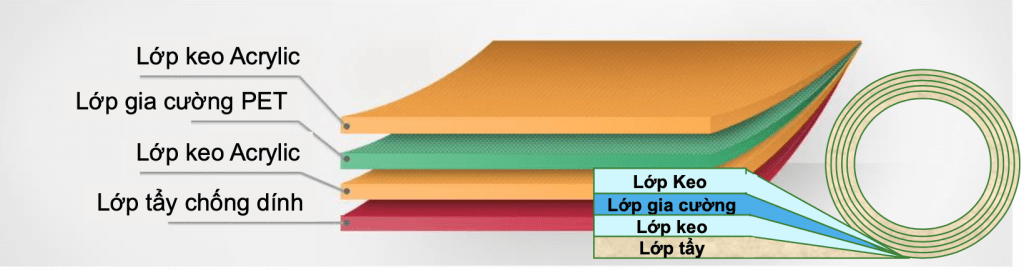

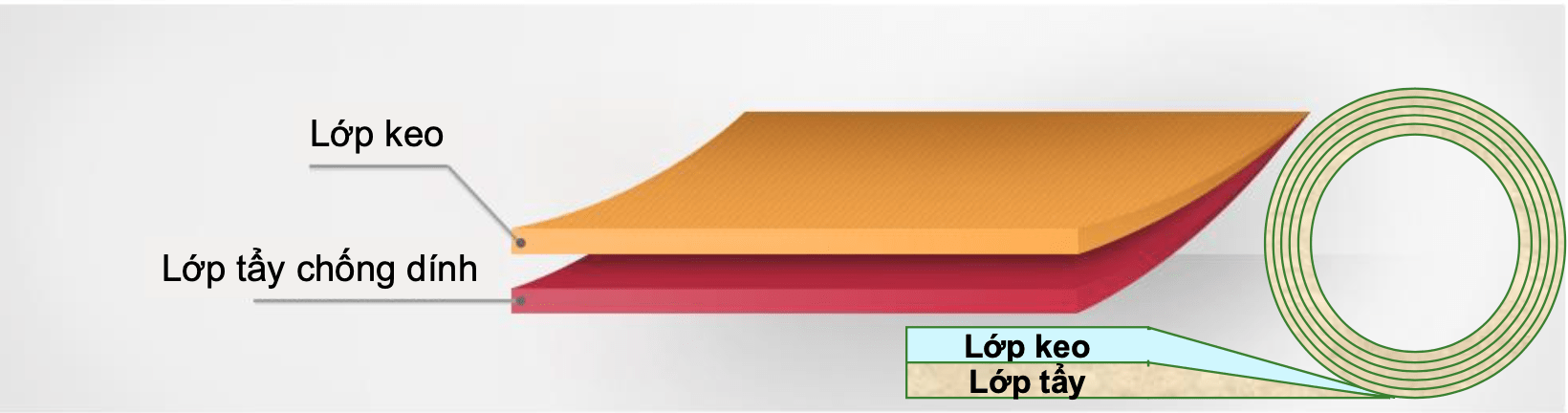

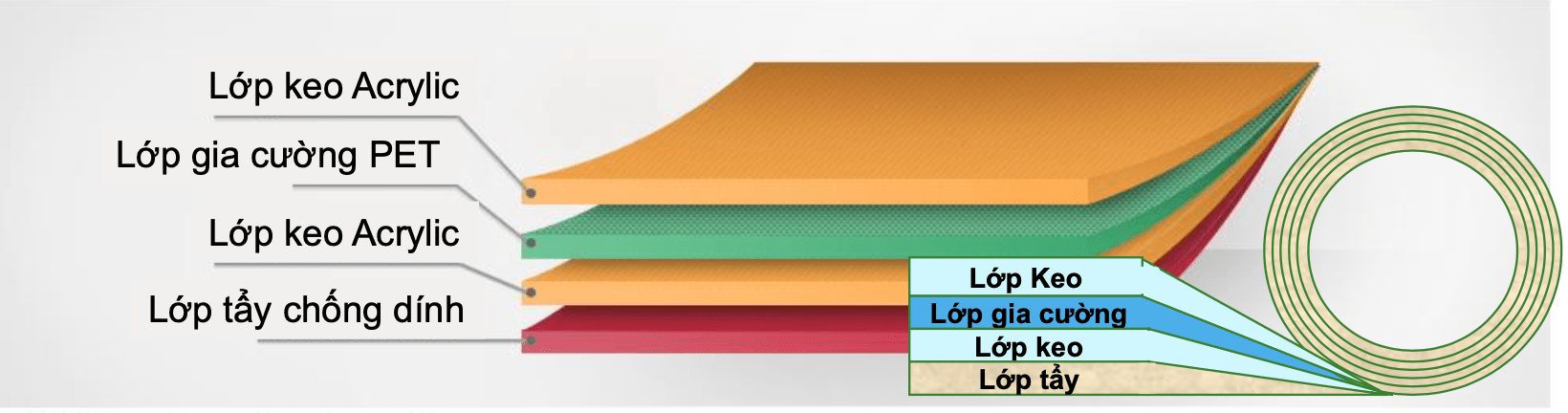

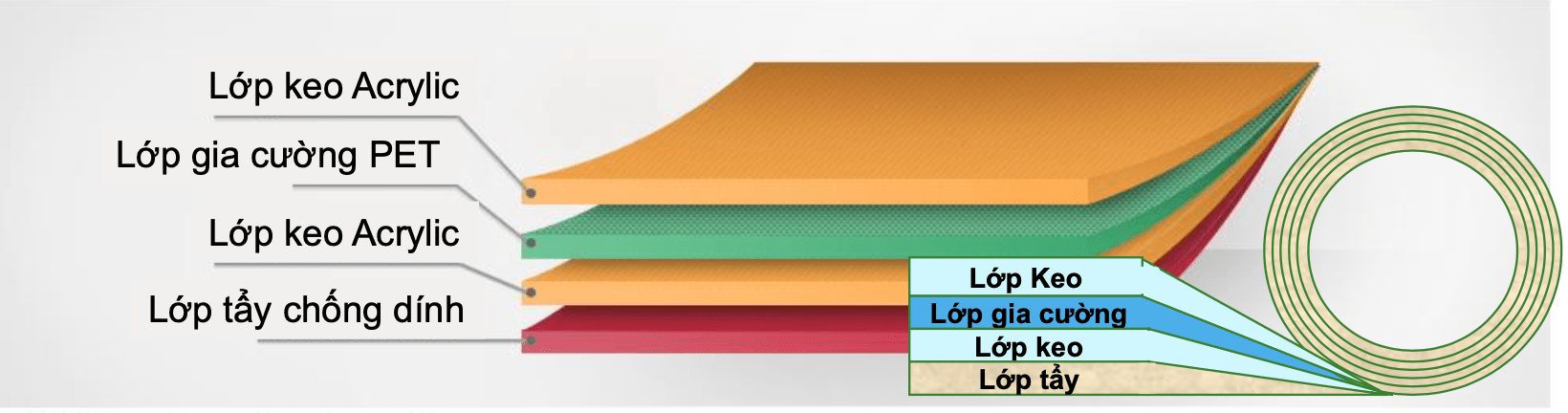

Based on their basic structure, double-sided tapes can be classified as follows:

Double-sided tape without reinforcement layer (transfer tape)

Double-sided tape with PET reinforcement layer

Double-sided tape with Tissue reinforcement layer

Comparison between double-sided tape without reinforcement layer and those with PET and Tissue reinforcement layers

Băng keo hai mặt không có lớp gia cường

- Dễ len lỏi sâu vào bề mặt.

- Giá rẻ hơn (do không có lớp gia cường).

- Mối dán mỏng hơn.

- Dùng cho các ứng dụng có mối dán 6. rất mỏng và vật liệu dán rất mềm.

- Dùng cho các ứng dụng yêu cầu tính trong suốt.

- Rất thích hợp để ghép dán với xốp.

- Thường được dùng ở dạng cuộn có bề rộng lớn.

Băng keo hai mặt có lớp màng gia cường PET

- Dễ thao tác, cắt, dập.

- Kích thước ổn định.

- Độ dày lên đến 0.3mm.

- Rất dễ cắt dập.

- Có thể gỡ ra, dán lại.

- Sản xuất được loại băng keo 2 mặt có 2 mặt keo khác nhau.

- Chịu được hơi ẩm, có thể dùng được ngoài trời.

Có thể cắt thành những cuộn có bề rộng nhỏ vài mm.

Băng keo hai mặt có lớp màng gia cường Tissue

- Dễ thao tác, cắt dập.

- Có thể dùng dán, ghép với xốp và vải.

- Dễ cắt dập.

- Cóthể gỡ bỏ.

- Dễ bị xé ngang.

- Chủ yếu dùng cho các ứng dụng trong nhà.

- Giá rẻ hơn Băng keo hai mặt không có lớp gia cường PET.

- Có thể cắt thàng những cuộn có bề rộng nhỏ vài mm.

The Best Brands of Double-Sided Tape

The best double-sided tape brands currently come from two companies: 3M and BowTape. Both brands offer applications and features such as:

- Bonding metals and high-temperature resistant materials.

- Surfaces with high surface energy.

- Foam and fabric.

- Surfaces with low surface energy.

- High-temperature and chemical-resistant bonding.

- Quick adhesion and bonding to low surface energy surfaces.

Depending on the specialized needs of customers, both 3M and BowTape offer lines of adhesive tape with unique characteristics and applications. Contact Hitta for technical advice tailored to your specific application scenarios.

☎️ Hotline: 090.8611.011 (Mr. Dương)

✉️ Email: hittajsc@hitta.vn

- Hitta JSC Là Nhà Phân Phối 3M chính thức tại Việt Nam

- Hiita là Nhà phân phối BowTape độc quyền tại Việt Nam

Popular Double-Sided Tape Lines

Acrylic Foam Double-Sided Tape:

- 3M: 5915, 4229P, 5952, B23F.

- BowTape: 704BE, 706BH, 708GXS, 711G, 723G.

Acrylic Double-Sided Tape:

- 3M: 4906, 4910.

- BowTape: 705T, 710T.

PE Foam Double-Sided Tape:

- BowTape: 398A, 398EW, 391W, 394B.

-

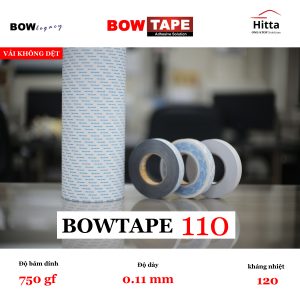

Bow Tape 110 (0.11 mm)

Bow Tape 110 (0.11 mm) -

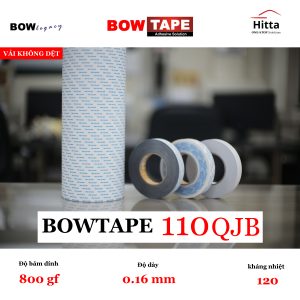

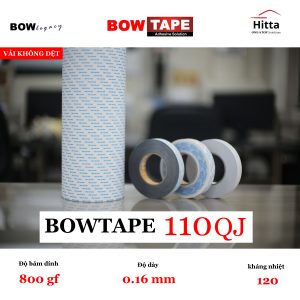

Bow Tape 110QJB (0.16 mm)

Bow Tape 110QJB (0.16 mm) -

Acrylic Foam Tape Bow Tape 723G (2.3 mm)

Acrylic Foam Tape Bow Tape 723G (2.3 mm) -

Acrylic Foam Tape Bow Tape 730W (3.0 mm)

Acrylic Foam Tape Bow Tape 730W (3.0 mm) -

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm)

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm) -

Bow Tape PE foam Tape 398A (0.8 mm)

Bow Tape PE foam Tape 398A (0.8 mm) -

Bow Tape PE foam tape 398EW (1.0 mm)

Bow Tape PE foam tape 398EW (1.0 mm) -

Bow Tape 391W (1.6 mm)

Bow Tape 391W (1.6 mm) -

Bow Tape 300NHK

Bow Tape 300NHK -

Acrylic Foam Tape – Bow Tape 711BH

Acrylic Foam Tape – Bow Tape 711BH -

Acrylic Foam Tape – Bow Tape 715B (1.5 mm)

Acrylic Foam Tape – Bow Tape 715B (1.5 mm) -

Bow Tape 3510PP (0.1 mm)

Bow Tape 3510PP (0.1 mm) -

Bow Tape 550 (0.17 mm)

Bow Tape 550 (0.17 mm) -

Acrylic Foam Tape – Bow Tape 7025THH

Acrylic Foam Tape – Bow Tape 7025THH -

Bow Tape 1750L (0.05 mm)

Bow Tape 1750L (0.05 mm) -

Bow Tape 590 (0.09 mm)

Bow Tape 590 (0.09 mm) -

Bow Tape 710SF (1.0 mm)

Bow Tape 710SF (1.0 mm) -

Bow Tape 3510B

Bow Tape 3510B -

Bow Tape 3505B

Bow Tape 3505B -

Bow Tape 716GS

Bow Tape 716GS -

Bow Tape 706BH (0. 6mm)

Bow Tape 706BH (0. 6mm) -

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive -

Bow Tape 110QJ (0.16 mm)

Bow Tape 110QJ (0.16 mm) -

Bow Tape 704WE (0.4 mm)

Bow Tape 704WE (0.4 mm) -

Bow Tape 706BH (0.6 mm)

Bow Tape 706BH (0.6 mm) -

Bow Tape 708GSX (0.8 mm)

Bow Tape 708GSX (0.8 mm) -

Acrylic Foam Tape Bow Tape 711G (1.1mm)

Acrylic Foam Tape Bow Tape 711G (1.1mm)