Plastics with low specific gravity help save fuel for vehicles. It is estimated that reducing the vehicle’s weight by 10% will lower fuel consumption by 5-7%. This is achieved by using 3M Hollow Glass Microspheres in the automotive industry.

Given the current economic conditions and environmental issues, creating fuel-efficient vehicles is one of the top priorities in the automotive industry. Advanced materials such as aluminum or carbon fiber are very useful; however, the use of plastics, particularly those with low specific gravity, has led to significant improvements for several reasons:

- Corrosion resistance, extending the vehicle’s lifespan.

- Ease of design and molding, allowing for creative and attractive designs.

- Safety, convenience, and cost-effectiveness.

- Recyclability.

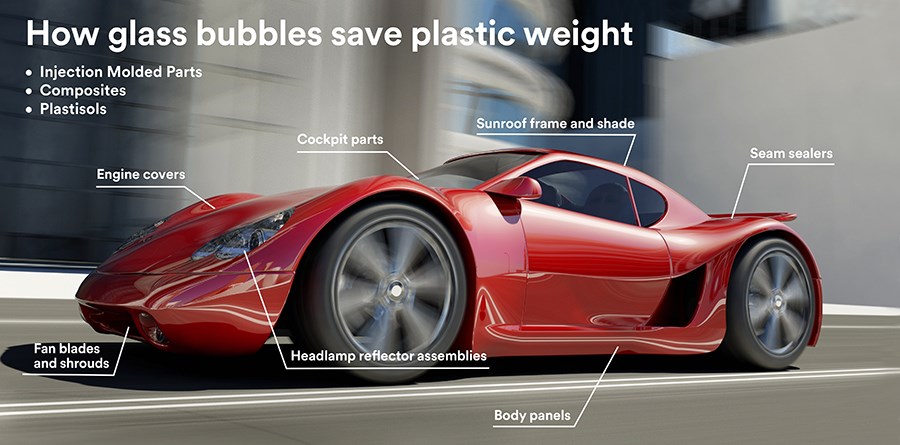

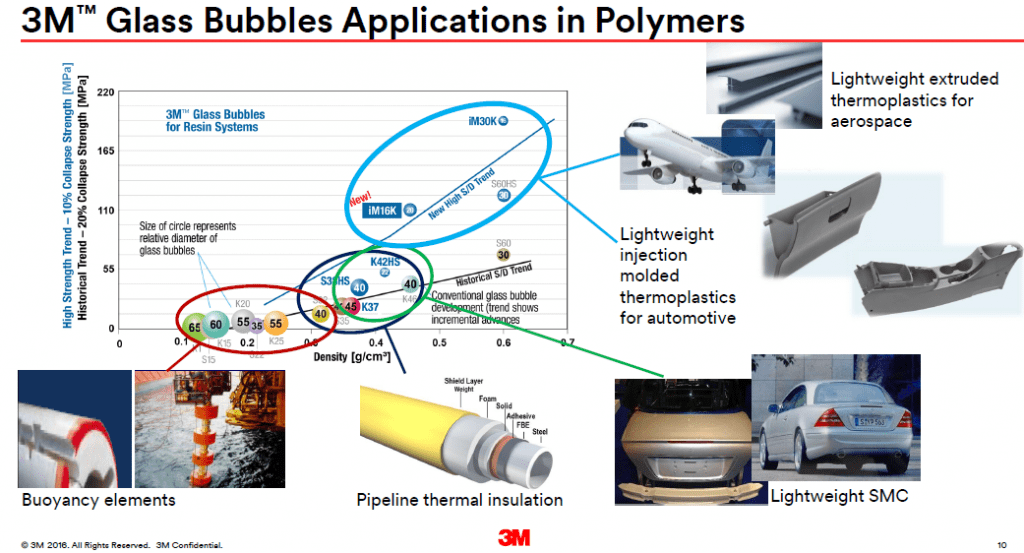

Today, further reducing the specific gravity of plastics has become crucial. With 3M Glass Bubbles, which have an ultra-light specific gravity (0.1-0.6 kg/cm³) and high durability, there has been a significant improvement in the weight reduction of plastic components in vehicles while still maintaining the physical and chemical properties of the plastics.

3M Glass Bubble with their special properties, are well-suited for extrusion, blow molding, and injection molding processes. They help improve the specific gravity of plastics by up to 25%. Currently, major car manufacturers such as Toyota, Hyundai, and Mercedes have widely adopted 3M Hollow Glass Microspheres in plastic components of their vehicles.

As a specialized distributor of 3M’s Advanced Materials in Vietnam, HITTA, with a technical team boasting over 10 years of experience, is ready to provide products and consultation services to address the performance-cost equation for our partners.

Contact us:

- ☎️ Hotline: 0565 33 68 79

- ✉️ Email: hittajsc@hitta.vn