- Keo dán nhựa composite | Cách chọn keo phù hợp

- Adhesive for bonding Acrylonitrile Butadiene Styrene (ABS) | Selecting the right adhesive

Understanding Polypropylene (PP)

Polypropylene is a thermoplastic polymer belonging to the polyolefin group. This means that PP can be formed at higher temperatures. At room temperature or low temperatures, PP exhibits material properties that are highly beneficial for various applications:

- High chemical resistance.

- High surface hardness.

- High strength and stiffness.

- Lower environmental impact compared to other plastic types.

- Excellent recyclability.

Additionally, Polypropylene is odorless and skin-friendly, making it ideal for numerous applications. PP plastic is also widely used in industrial applications. Some notable applications include:

- In automotive, machinery, and aircraft manufacturing.

- In civil engineering.

- In electrical engineering.

- In consumer goods.

- In pharmaceuticals.

- In the food industry.

- As interior linings for various appliances.

- Cables and wire casings.

- Transformer casings.

- Sheet goods and injection-molded parts.

- Disposable plastic cups.

- High-heeled shoes.

- Bottle caps.

- Interior linings for passenger vehicles and impact-reducing elements.

Why is Polypropylene difficult to bond?

Adhering to polypropylene is a highly complex process. While the material offers many advantages to users due to its flexibility, a significant drawback is its extremely low density and thus very low surface tension, especially compared to metals. Additionally, its surface wetting ability is entirely different.

The surface tension of a material can be determined by the way water droplets coat its surface. If the liquid beads up instead of spreading out to wet the entire surface, then this is a low surface energy (LSE) surface.

Due to low surface energy (LSE) and poor wetting ability, bonding to polypropylene can be challenging. Therefore, selecting the appropriate type of PP adhesive and surface pre-treatment are two crucial factors in adhering to polypropylene. To understand more about surface energy, please read the following article:

Adhering Polypropylene with Two-Part Epoxy Adhesive

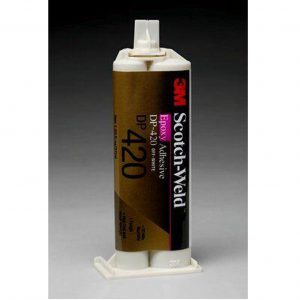

Two-part adhesives are typically epoxy, polyurethane, or methyl methacrylate resins. The distinctive feature of two-part adhesives is that they complement each other’s properties to enhance adhesion. In the case of two-part epoxy adhesive: one part is epoxy resin and the other part is the hardener.

Both components are mixed together in specific proportions and undergo a chemical reaction with each other. The optimal mixing ratio is crucial because if the ratio is incorrect, insufficient curing may occur, leading to potential bond failure.

As per regulations, two-part epoxy adhesives do not contain solvents. Epoxy adhesives are often chosen for bonding larger surfaces. Application of a primer may be applied beforehand (not mandatory).

Advantages of two-part epoxy adhesive:

- Short processing time.

- Quick curing phase (full cure occurs within minutes).

- Can bond with a variety of different materials.

- Optimal impact and shear resistance.

- Suitable for flexible joints.

Adhering Polypropylene with Two-Part Acrylic Adhesive

Acrylic adhesive can be applied for bonding both polypropylene and polyethylene, similar to epoxy resin. The two components of the adhesive complement each other’s properties to enhance adhesion. The advantage of two-part acrylic adhesive is that it can bond plastics without the need for surface pre-treatment using a primer.

In addition to PP and PE, two-part acrylic adhesive bonds many other types of plastics, such as PMMA or ABS. Materials like metals and alloys, wood, ceramics, and stone can also be bonded together using two-part acrylic adhesive with high durability.

Advantages of Two-Part Acrylic Adhesive:

- Bonds low surface energy materials without the need for surface pre-treatment.

- Acrylic adhesive provides high water resistance, as well as good impact and shear resistance.

- Excellent resistance to UV radiation.

- Good resistance to chemicals, high temperatures, and degradation.

- Short and simple application process.

- Short initial bond formation time.

- Highly durable bonds over time.

Adhering Polypropylene with Super Glue

Cyanoacrylate adhesive, also known as super glue, is a single-component adhesive known for its exceptionally high final bond strength and extremely fast curing time. The application process is remarkably simple. After cleaning the surface and applying primer meticulously, the adhesive needs to be applied thinly but with sufficient quantity, and the two substrates are then pressed together with high pressure, briefly.

Cyanoacrylate adhesive cures instantly, making it suitable for bonding nearly all materials including PP, PE, ABS, metals, stone, wood, ceramics, rubber, leather, and many others. Additionally, cyanoacrylate adhesive has the ability to fill voids effectively and is ideal for porous materials.

Advantages of super glue:

- Rapid curing.

- Excellent tensile and shear strength.

- No solvents.

- Perfect for small areas.

- Easy and clean application.

Considerations When Bonding Polypropylene

Surface pretreatment is crucial when bonding polypropylene plastic. When using adhesives such as two-part acrylic or epoxy, applying a primer is not mandatory, but care must be taken to ensure it does not adversely affect the bond.

The application process typically adheres to the following steps:

- Use the product as directed according to its specifications.

- Depending on the adhesive used, apply it to one or both surfaces (substrates).

- Secure the two substrates together if necessary. This step is important because smooth materials like PP may shift or change positions before the curing process is complete if not secured.

- Immediately wipe away any excess adhesive that spills or leaks using a lint-free cloth or paper towel.

By following these steps, you can effectively bond polypropylene and ensure a strong and reliable adhesion.

Contact information

Hitta specializes in providing various types of adhesive and tape products tailored for both industrial and commercial sectors. Contact us for the highest efficiency solutions with the lowest costs.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn