Silicone and sealant are two types of adhesives with minimal information available, and very few people truly understand their intricacies. Consequently, the precise applications for optimal usage in construction remain ambiguous. In this article, Hitta will provide detailed insights and guidance on everything you need to know about silicone & sealant in construction.

Silicone & Sealant in the Construction Industry

In interior construction, from flooring to lighting, plumbing pipes, wooden furniture, and most other major components, detailed information regarding quality and type is readily available. However, silicone and sealant are seldom mentioned.

People often overlook the need for specialized types of silicone and sealant, assuming that ‘any type will do,’ even among construction contractors and interior designers.

We only think about adhesives when they begin to show signs of mold, peeling, discoloration, and aesthetic degradation. Worse still, this deterioration can even affect the quality of the structure.

Contractors and the Selection of Silicone & Sealant

Why You Shouldn’t Choose Cheap Silicone & Sealant

Cheap silicone and sealant products may seem like a cost-effective solution at first glance, but they often lack quality and durability over time. These products are typically manufactured with low-quality or non-standard materials, making them prone to cracking, fading, and peeling, thus compromising the aesthetic appeal and visual appeal of a room.

Furthermore, using inexpensive silicone and adhesives can lead to health issues, especially when they become moldy or contaminated with bacteria. These products may contain harmful chemicals that can be released into the air, posing health risks to humans.

Therefore, to ensure product quality and durability, contractors should opt for silicone and sealant from reputable and certified brands. While they may be more expensive upfront, investing in high-quality products will save on maintenance and repair costs in the long run, providing customer satisfaction and peace of mind.

Why Choose High-Quality Silicone & Sealant?

- Opting for high-quality silicone and sealant ensures superior, long-lasting performance for construction projects, alleviating concerns about deterioration within a few years.

- Good-quality sealing materials aren’t significantly more expensive.

- Even with much higher-priced options, silicone and sealant constitute a very, very small portion of the total cost.

Furthermore, premium silicone and sealant products guarantee durability and longevity, safeguarding structures and surfaces from water, moisture, mold, and bacteria. Top-tier silicone and sealant products are typically manufactured from high-quality materials and meet stringent quality standards, ensuring aesthetic appeal and human health safety.

High-quality silicone & sealant completely address various issues:

- Sealant showing black spots and turning black in areas – mold growth is occurring.

- Adhesive beginning to turn yellow.

- Silicone & sealant starting to harden and become brittle, cracking. Silicone & sealant beginning to peel from joints, allowing water infiltration.

Notably, premium silicone and sealant products often possess heat resistance, water resistance, UV resistance, and antimicrobial properties, enabling their use in harsh environments such as bathrooms, kitchens, and outdoor areas.

Choosing high-quality silicone and adhesive also saves on future maintenance and repair costs because of their high durability and infrequent need for replacement.

In summary, selecting high-quality silicone and adhesive provides customer satisfaction and peace of mind, ensuring aesthetic appeal and human health safety, while also saving on future maintenance and repair costs.

Understanding the Basics of Sealant

Sealant, also known as caulking compound or putty, is essentially a type of chemical used to seal gaps, joints, and spaces between assembled parts or two separate materials.

The function of sealant is to create a protective barrier to prevent water, air, sweat, or other elements from infiltrating into the material and substrate to which it is adhered.

There are several principles in the operation of sealant:

- Sealant must have adhesion to the surface, or else water may seep in.

- Sealant should not degrade or change when exposed to the substances it is sealing.

- Sealant must have elasticity to adapt to material movements without separating, cracking, or tearing.

- Sealant must resist other chemicals and ultraviolet rays to ensure its longevity.

Sealants play a crucial role in various industries, including construction, automotive, and manufacturing, providing protection against environmental factors and ensuring the integrity of structures and assemblies. Proper selection and application of sealants are essential to achieving effective sealing and prolonging the lifespan of materials and structures.

Silicone or Sealant?

Indeed, there’s a widespread misconception worldwide, including in Vietnam, that “silicone” is synonymous with “sealant.” Hitta encounters this issue daily, even with contractors.

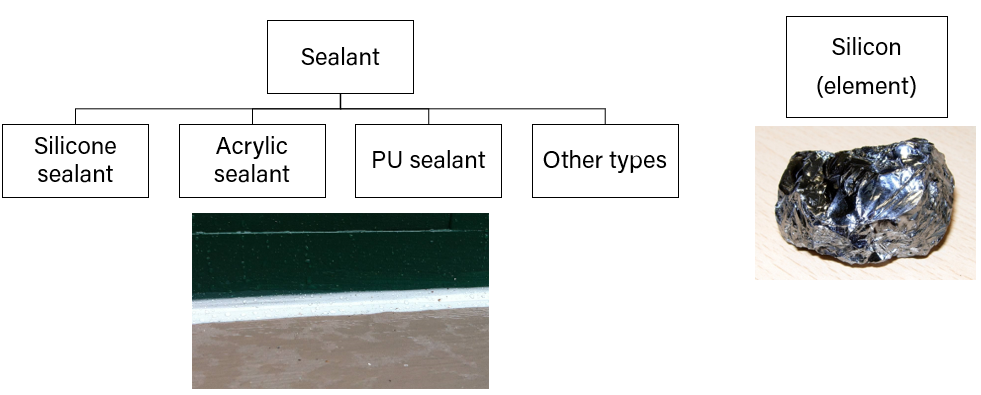

“Sealant” is the correct and general term for the chemical used for sealing purposes.

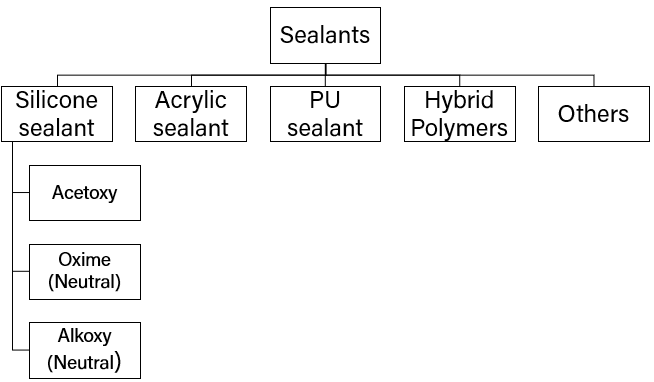

“Silicone” is just one type of sealant. Additionally, there are acrylic sealants, polyurethane sealants, etc. Silicone sealant happens to be the most common type.

(It’s worth noting that silicon can also be used in other things, such as silicone gel patches and in cosmetic surgeries. Silicone is also a component used in computers and processors – these are not called sealants.)

Correcting this misconception is crucial for ensuring clarity in communication within the construction and manufacturing industries. It’s essential to educate individuals about the different types of sealants available and their respective applications to make informed decisions regarding sealing materials.

Types of Sealant

There are numerous types of sealants available for sealing purposes. The most common is silicone sealant, which explains why people often refer to all sealants as “silicone”.

In construction, there are primarily two types of adhesives commonly used: silicone adhesive and acrylic adhesive. PU (Polyurethane) sealant is often utilized in exterior construction projects, whereas hybrid polymers are typically too costly for contractors to use indoors.

Silicone sealant

Silicone sealant is commonly applied in bathrooms and kitchens, glassworks, and window installations.

Silicone sealant is commonly found as a rubbery material along the edges of sinks. It’s a highly flexible sealing compound suitable for various applications and excels when used on glass and metal. It’s relatively affordable, offers excellent elasticity, and provides good resistance. Silicone sealant is easy to apply and has an aesthetically pleasing appearance.

However, silicone sealant cannot be painted, and its adhesion is limited both in terms of durability and the substrate to which it can adhere.

Advantages:

- Good overall performance.

- Permanent elasticity.

- Easy to use.

- Excellent adhesion on non-porous materials like glass and metal.

- Very good UV resistance.

- Waterproof.

Disadvantages:

- Cannot be painted.

- Poor adhesion on porous materials like wood and tile.

- Lacks a smooth finish – tends to have a slightly cloudy appearance.

Types of Silicone Sealant

Silicone can be divided into various types. There are acetoxy silicone, oxime silicone (neutral silicone), and alkoxy silicone or alkaline silicone (rarely used due to high cost).

Acetoxy silicone is distinguished by its odor during application: it has a vinegar-like smell, indicating strong acidity. Oxime silicone or neutral silicone typically has no odor.

Generally, oxime silicone performs better in most aspects, including adhesive strength, compatibility with various materials, and resistance, but it’s also more expensive.

Pure Silicone and Diluted Silicone

Silicone can be diluted to make it more cost-effective. Producing 100% pure silicone adhesive (such as Bathroom & Kitchen Sealant) is very expensive, which is why most adhesive brands offer various quality levels from the cheapest to the most expensive. The quality of silicone adhesive is largely determined by its purity.

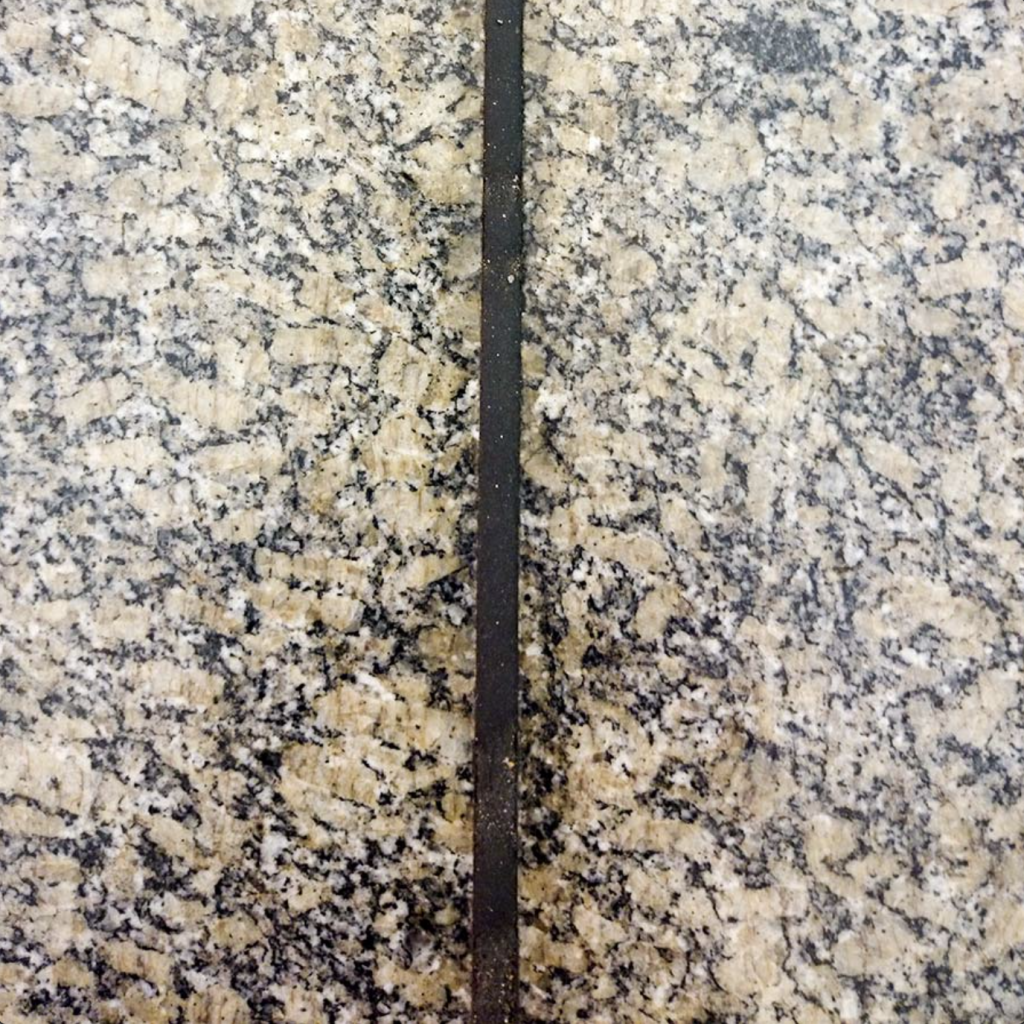

When used on slightly porous materials like natural stone, limestone, or granite, diluted silicone and other diluents in silicone adhesive can migrate out of the adhesive body and into the stone, causing discoloration. This is called leaching, and it’s a common issue with cheap silicone adhesives.

Silicone sealant for use in bathrooms and kitchens

Silicone sealant is a preferred option for use in bathrooms and kitchens, as many sealing compounds require anti-fungal and anti-mold properties. This can be achieved by incorporating chemicals to inhibit the growth of mold.

Hitta has heard industry professionals say that the acid in acetoxy silicone will kill fungal spores. This is not true. Silicone sealant has no inherent ability to resist the growth of mold.

Do not use regular silicone sealant in bathrooms and kitchens as you may notice mold within two weeks. Always opt for specialized silicone sealant for bathrooms & kitchens such as Bostik S546.

The quality and effectiveness of anti-fungal properties depend on the formula and concentration of anti-fungal chemicals in the sealant. Not all anti-fungal sealants are the same.

Bostik S546 is specially formulated for use in hot and humid environments and is favored by many 5-star hotels in Vietnam for its superior properties.

However, these anti-mold properties cannot replace regular bathroom and joint maintenance. There is always a lifespan for anti-mold properties. Generally, the dirtier the bathroom, the shorter the lifespan. No sealant will remain 100% mold-free forever in a dirty environment.

Here are some tips to prevent silicone from molding:

- Keep the bathroom well-ventilated.

- After hot showers, allow hot air and steam to escape the bathroom.

- Try not to let water and soap residue accumulate on the sealant as much as possible.

- Clean the joints regularly.

- Perpetually moist areas tend to develop mold. Try to keep those areas dry.

It’s important to note that the better the anti-fungal properties of silicone, the longer it will resist mold. The lifespan can be up to 20 years with good anti-mold sealant, under proper cleaning conditions.

Additionally, if you’re using surfaces like granite or quartz, Hitta strongly recommends using clear silicone, usually the 100% pure type, such as our Bostik S546.

Acrylic Sealants

Acrylic Sealants are commonly used around walls, between walls and baseboards, door frames, air conditioning ducts, and pipes (especially penetrating walls).

Acrylic Sealants are sometimes referred to by long-standing Chinese contractors as 泥土 (earth) due to their appearance resembling a kind of clay. In fact, acrylic sealants were first sold in powder form. This is one of the old-fashioned caulking technologies still used in construction due to its flexibility and low cost.

Acrylic sealant lacks the flexibility and rubber-like appearance of silicone; instead, acrylics resemble the wall and can be painted over. For this reason, acrylic sealant is often found on joints near the wall, such as baseboards, door frames, and penetrating walls.

Acrylic caulking is not fully elastic (they are plastic elastic) and is not recommended for use in applications exposed to long-term or continuous contact with water.

Advantages:

- Affordable.

- Very easy to use and tool.

- Paintable.

- Good adhesion to many substrates.

Disadvantages:

- Not fully elastic.

- Cannot be used in areas of frequent water exposure.

Two things to note about acrylic caulk are shrinking and cracking. As a water-based caulking material, acrylic sealant will lose moisture during the curing process and shrink. If it shrinks too much, it can crack over time.

PU Sealant

PU sealant or polyurethane (PU) sealant is mainly used in expansion joints in construction, meaning the sealant should not be used in household applications. In most applications, hybrid polymers will easily outperform PU sealant in any specification.

PU sealant is applied to door frames and walls:

Advantages:

- Affordable.

- Fully elastic.

- High adhesion strength on porous substrates like concrete.

- Good bonding strength on other materials.

- Paintable.

Disadvantages:

- Not UV resistant – will crack over time.

- Contains isocyanate – harmful to health during curing.

Hybrid Polymer sealant

Suitable applications: Bathrooms, kitchens, any joints, bonding agents, etc.

Anywhere silicone sealant can be used, hybrid polymer sealant can also be used. Anywhere acrylic sealant can be used, hybrid polymer sealant can be used as well (it can also be painted).

However, that doesn’t mean it can be used as a direct replacement everywhere. There are specific areas where using traditional silicone/acrylic may be more appropriate. For example:

Hybrid Polymer sealant also has mold resistance capabilities but may still develop mold over time. Removing Hybrid Polymer Sealant when resealing joints is much more difficult due to its adhesive strength compared to using silicone sealant.

Hybrid Polymer sealant does not have the matte appearance like acrylic, meaning it may not blend well with indoor walls.

In most cases, Hitta still recommends traditional options for their specialty and cost-effectiveness.

Advantages:

- Extremely high bonding strength.

- Adheres to most materials.

- Permanent elasticity.

- Crystal-clear appearance.

- Resistant to mold and mildew.

- Paintable.

- Low odor, very low VOC.

Disadvantages:

- Less glossy than silicone – slightly cloudy appearance.

- High adhesion, difficult to repair joints.

- Slightly harder to achieve perfect finish (higher viscosity).

- Highest price.

The superior feature of hybrid silicone polymer lies in challenging and complex applications, such as on constantly wet surfaces or even underwater. They also perform well in adverse conditions, such as on surfaces with stubborn residual adhesive that cannot be removed.

The high bonding strength makes this type of adhesive a worthy candidate for permanently sealing leaks, such as on rooftops.

Silicone Sealant Solution for Construction

Hitta specializes in providing specialized adhesives and tapes for both industrial and commercial sectors. Contact us for the most effective solution with the lowest cost, especially in the construction industry.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn