Design engineers face immense pressure as they navigate numerous challenges and decisions at every stage of a project. One particularly tough decision is selecting the most effective bonding solution.

Thanks to advancements in science and technology, tape is no longer just for sealing cartons, simple components, or household items. It is now emerging as the future solution, replacing traditional methods that have been used for decades. Gradually, tape is transforming various industries due to its advantages and ability to expand the boundaries of bonding different materials and surfaces.

A Brief History of Adhesion

For many years, engineers have relied on screws, bolts, mechanical fasteners, rivets, welding, and liquid adhesives to create lasting bonds between materials. While these methods can work well for specific projects, they often lead to unintended consequences:

- Bolts and Screws: Mechanical fasteners can significantly increase the weight of the product and, in some cases, affect its performance. They also do not handle vibrations well and can loosen over time.

- Rivets: A lighter solution that perforates the material, but it creates uneven bonds with stress points that can fail under sufficient force.

- Welding: Produces permanent, strong joints but is time-consuming and disruptive to the assembly process, affecting efficiency.

- Liquid Adhesives: Create lightweight, high-performance bonds but require long drying times and can be time-consuming to apply.

Advantages of BowTape Reinforced Tape

Strong Adhesion

Thanks to recent innovations in technology, reinforced tape has become one of the most durable and powerful adhesive materials available. For instance, BowTape exhibits exceptionally high bonding strength, adhering extremely securely and outperforming traditional bonding solutions by being ten times stronger than rivets. Besides its robust bonding capabilities, consider its versatility. Most assembly options work with attachments from metal to metal or plastic to plastic, but reinforced tape can create a secure bond between surfaces of different materials.

Uniform Force Distribution

Speaking of durability and flexibility, reinforced tape can be utilized in numerous bonding applications to replace rivets, welding, and other fasteners with concentrated stress points. The strips of tape running along the surface distribute stress across the entire area of the tape, rather than just at a specific point. The high-performance and permanent bonds of reinforced tape manage stress better than any other solution.

Enhanced Aesthetics

When using BowTape reinforced tape, design engineers can expand their options for a more aesthetically pleasing appearance. This is because they don’t have to deal with protruding rivets or welding burns. BowTape reinforced tape creates a tight connection without adding extra bulk or unsightly joints.

Furthermore, the lightweight nature of reinforced tape can help reduce material thickness, something not achievable with welding or mechanical screws. After bonding, there’s only a smooth, seamless bond, operating beautifully and efficiently. This is crucial in any design environment where aesthetics and exterior are highly visible, such as automobiles or elevators.

High Productivity

In terms of production and installation, time is always money. BowTape reinforced tape is easy to use and install, speeding up assembly, reducing labor hours, and lowering overall production costs.

Moreover, with the simplicity of using BowTape reinforced tape, manufacturers can implement automation processes that allow reinforced tape to be distributed and applied faster than ever before, facilitating efficient, precise, and consistent assembly processes. Automated systems and rationalized robots streamline the assembly of customized products in ways never before possible with the application of reinforced tape.

BowTape Reinforced Tape Products

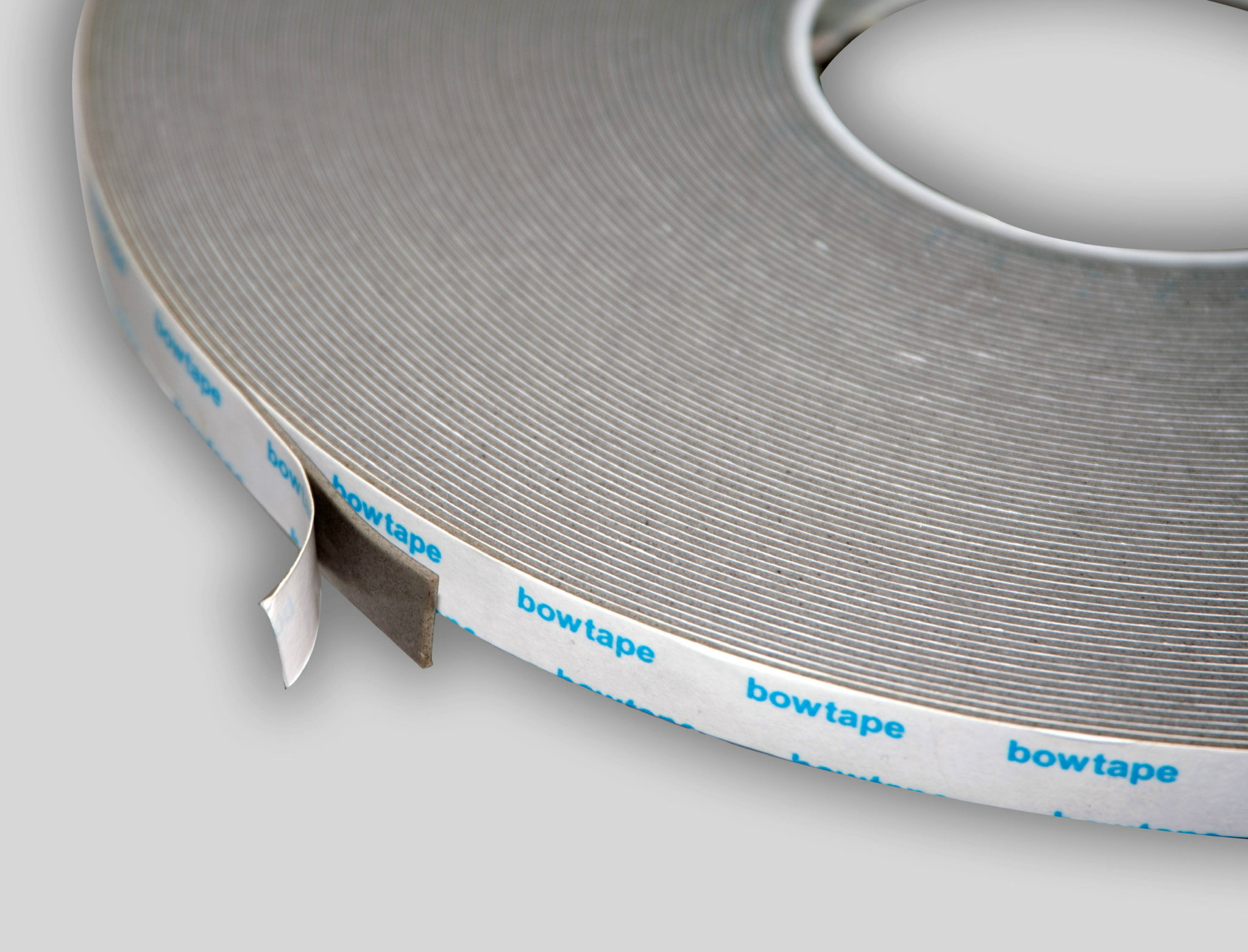

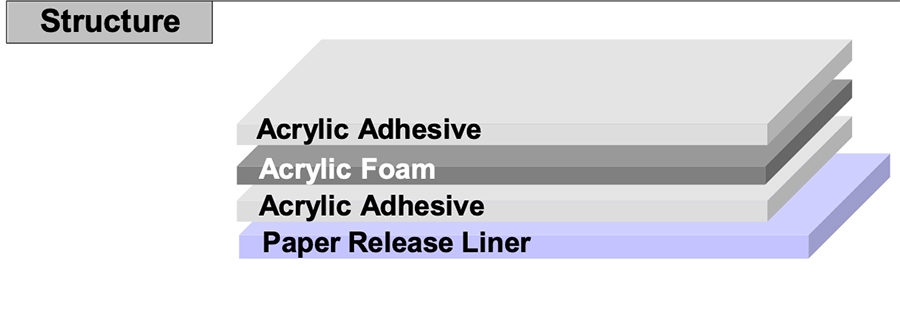

Hitta introduces reinforced tape solutions from the leading BowTape brand in the market. BowTape reinforced tape is designed for high adhesion and can replace rivets, screws, and welds. BowTape consists of three layers, including two adhesive layers and a foam layer in between, protected by a liner.

-

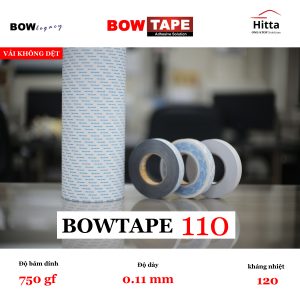

Bow Tape 110 (0.11 mm)

Bow Tape 110 (0.11 mm) -

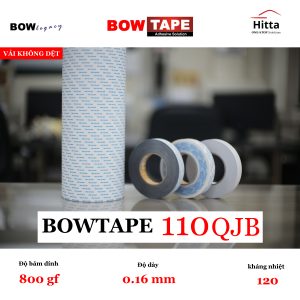

Bow Tape 110QJB (0.16 mm)

Bow Tape 110QJB (0.16 mm) -

Acrylic Foam Tape Bow Tape 723G (2.3 mm)

Acrylic Foam Tape Bow Tape 723G (2.3 mm) -

Acrylic Foam Tape Bow Tape 730W (3.0 mm)

Acrylic Foam Tape Bow Tape 730W (3.0 mm) -

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm)

Acrylic Foam tape with LSE coating – Bow Tape 708GLM (0.8 mm) -

Bow Tape PE foam Tape 398A (0.8 mm)

Bow Tape PE foam Tape 398A (0.8 mm) -

Bow Tape PE foam tape 398EW (1.0 mm)

Bow Tape PE foam tape 398EW (1.0 mm) -

Bow Tape 391W (1.6 mm)

Bow Tape 391W (1.6 mm) -

Bow Tape 300NHK

Bow Tape 300NHK -

Acrylic Foam Tape – Bow Tape 711BH

Acrylic Foam Tape – Bow Tape 711BH -

Acrylic Foam Tape – Bow Tape 715B (1.5 mm)

Acrylic Foam Tape – Bow Tape 715B (1.5 mm) -

Bow Tape 3510PP (0.1 mm)

Bow Tape 3510PP (0.1 mm) -

Bow Tape 550 (0.17 mm)

Bow Tape 550 (0.17 mm) -

Acrylic Foam Tape – Bow Tape 7025THH

Acrylic Foam Tape – Bow Tape 7025THH -

Bow Tape 1750L (0.05 mm)

Bow Tape 1750L (0.05 mm) -

Bow Tape 590 (0.09 mm)

Bow Tape 590 (0.09 mm) -

Bow Tape 710SF (1.0 mm)

Bow Tape 710SF (1.0 mm) -

Bow Tape 3510B

Bow Tape 3510B -

Bow Tape 3505B

Bow Tape 3505B -

Bow Tape 716GS

Bow Tape 716GS -

Bow Tape 706BH (0. 6mm)

Bow Tape 706BH (0. 6mm) -

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive

Transparent Reinforcement Tape Bow Tape 710T (thickness 1.0 mm) Self-Adhesive -

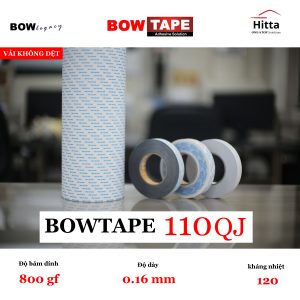

Bow Tape 110QJ (0.16 mm)

Bow Tape 110QJ (0.16 mm) -

Bow Tape 704WE (0.4 mm)

Bow Tape 704WE (0.4 mm) -

Bow Tape 706BH (0.6 mm)

Bow Tape 706BH (0.6 mm) -

Bow Tape 708GSX (0.8 mm)

Bow Tape 708GSX (0.8 mm) -

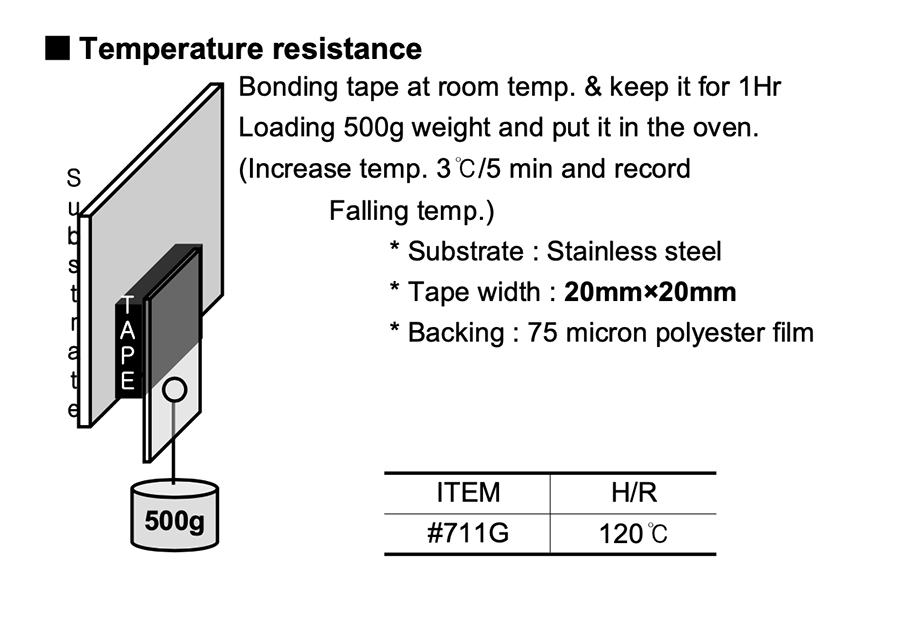

Acrylic Foam Tape Bow Tape 711G (1.1mm)

Acrylic Foam Tape Bow Tape 711G (1.1mm)

Applications of BowTape Reinforced Tape Solution

Due to its superior characteristics, reinforced tape is widely used in various industries such as automotive manufacturing & assembly, elevators, electronics & home appliances, signage & decorations, and more. Please refer to the links below for more details on applications:

- Giải pháp băng keo cường lực

- Giải pháp băng keo cường lực cho thang máy

- Keo PSA giải pháp kết dính của tương lai

For detailed consultation on BowTape reinforced tape solutions, please contact Hitta for the best support.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn