High-performance adhesive solution for corner sealing of doors and windows. Thanks to its ideal viscosity balance, this technology ensures a clean and easy corner sealing process, with optimal joint filling and sealing properties.

Types of adhesive for aluminum doors and windows

Currently, there are various types of adhesive for aluminum doors and windows on the market, with the most common being polyurethane (PU), silicone, and epoxy adhesives.

PU adhesive:

Advantages: PU adhesive has excellent adhesion, weather resistance, and resistance to external environmental impacts. It is UV-resistant, waterproof, and provides good vibration and noise reduction.

Disadvantages: PU adhesive has a longer drying and hardening time compared to other types of adhesives, requiring a longer waiting time before using the door or window.

Features: PU adhesive is often used in construction projects due to its weather resistance, waterproofing, and sealing properties.

Silicone adhesive:

Advantages: Silicone adhesive has good heat resistance, water resistance, waterproofing, UV resistance, excellent adhesion, flexibility, and ease of application.

Disadvantages: Silicone adhesive is not resistant to chemical and mechanical impacts like PU adhesive, requiring multiple layers when increased thickness is needed.

Features: Silicone adhesive is commonly used in the installation of aluminum doors, windows, tempered glass, and PVC panels.

Epoxy adhesive:

Advantages: Epoxy adhesive has high adhesion and load-bearing capacity, high-temperature resistance, chemical resistance, waterproofing, and sealing properties.

Disadvantages: Epoxy adhesive is difficult to work with, requiring high technical skills, and has a longer drying time compared to other types of adhesives.

Features: Epoxy adhesive is often used in the installation of equipment in the industrial sector, machinery assembly, mold making, and repairing ceramic and porcelain items.

Methods of bonding aluminum doors and windows

Traditional method: Before joining, adhesive is directly applied to the gaps in aluminum door corners.

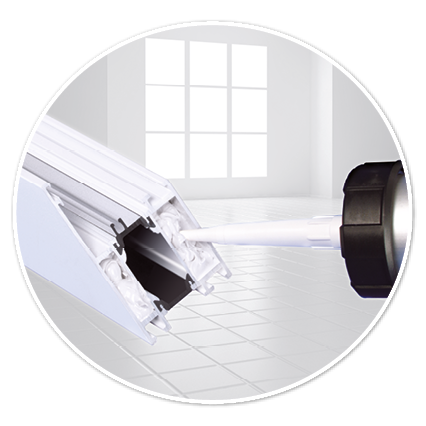

Injection method: This method applies to aluminum windows, doors, and folding blinds that are joined at corners. The process involves drilling a hole at a pre-determined location, then injecting adhesive into it.

Corner bonding for aluminum profiles: Aluminum profiles are placed on existing windows. Single aluminum profiles are assembled into a frame at cut corners with aluminum cast corner connections and securely locked with adhesive.

Sealing the diagonal edges of aluminum: The purpose is to protect the aluminum cut edges from corrosion; aluminum edges need to be effectively shielded from air and moisture.

Applications & Benefits of Aluminum Door and Window Adhesive

- Installing aluminum windows: Adhesive is used to install aluminum windows due to its weather resistance, waterproofing, and strong load-bearing capacity. It helps reduce vibration and noise when opening and closing windows and ensures a tight seal for the interior space.

- Installing aluminum doors: Adhesive is used to install aluminum doors due to its high load-bearing capacity and strong adhesion, ensuring tight and safe doors.

- Installing PVC panels: Adhesive is used to install PVC panels, especially in construction and interior decoration projects. It reduces vibration and noise, withstands environmental impacts, and ensures a tight seal for the interior space.

- Installing tempered glass: Adhesive is used to install tempered glass due to its high impact resistance and load-bearing capacity, making the glass safer and ensuring a tight seal for the interior space.

- Repairing aluminum doors and windows: Aluminum door and window adhesive is also used to repair damaged or malfunctioning parts during use. It helps restore the original function of doors and windows and ensures a tight seal.

The benefits of aluminum door and window adhesive include: enhancing aesthetics, reducing vibration and noise, retaining heat and waterproofing, ensuring safety and a tight seal for the interior space. Additionally, adhesive helps prolong the lifespan of doors and windows and reduces repair costs during use.

Requirements for aluminum door and window adhesive

- High adhesion: Aluminum door and window adhesive needs to have high adhesion to ensure that panels and door frames are securely connected, avoiding expansion, fading, cracking, or peeling when subjected to loads and environmental pressures, temperature, and humidity.

- Good water resistance: Aluminum door and window adhesive needs to withstand water and prevent water penetration in humid environments or when exposed to rain.

- Resistance to aging: Aluminum door and window adhesive needs to resist aging and be unaffected by sunlight, air, temperature, and time.

- High durability: Aluminum door and window adhesive needs to have high durability and resist external influences, ensuring long-term durability and minimizing repair or replacement costs.

- Health safety: Aluminum door and window adhesive needs to be safe for human health, environmentally friendly, and user-friendly.

- Ease of use and application: Aluminum door and window adhesive needs to be easy to use and apply, without causing difficulties for installers, and ensure accuracy during installation.

Purchase adhesive for aluminum doors and windows

Hitta is pleased to introduce specialized adhesive for aluminum door corner bonding from France – Bostik adhesive with specific product lines tailored for the construction industry.

The manufacturer’s name itself speaks to the specialized application of the Bostik Aluseal product: “Alu” in “Aluminium” – Aluminum and “Seal” in “sealant” & “seal” – sealing compound & closure sufficiently indicates that the product is designed for bonding aluminum door corners/aluminum window frames!!

Advantages:

- Specialized in bonding aluminum door corners, aluminum window frames, aluminum shutter doors.

- Sealing small chamfer joints in aluminum door/window production.

- Fast curing.

- Provides a flexible cushioning layer for facing joints and chamfer joints of different connections in metal window frames, aluminum blinds.

- Effective in preventing corrosion of joints due to oxidation at the edges.

- Suitable for both interior and exterior use.

- Good flexibility.

- Good wetting and sealing properties.

Technical specifications:

| Product Name | Bostik Aluseal Adhesive/Silicone/Sealant |

|---|---|

| Application | Corner bonding of aluminum doors, aluminum frame, aluminum flash |

| Waterproof Capability | Excellent |

| Surface Drying Time | 25 – 35 minutes |

| Curing Time | Minimum 21 days for a 2mm thick film |

| Application Temperature | 5 – 30°C |

| Operating Temperature | 0 – 70°C |

| Shore A Hardness | 40 – 50 |

| Adhesive Strength | Good |

Additionally, there are 2 products that can be used as adhesives for aluminum doors and windows:

Hitta specializes in supplying various types of specialized adhesives and tapes for both industrial and commercial sectors, serving as an authorized distributor of Bostik in Vietnam. Contact us for advice on the most effective solutions at the lowest cost.

![]() Hotline: 090.8611.011 (Mr. Dương).

Hotline: 090.8611.011 (Mr. Dương).

![]() Email: hittajsc@hitta.vn

Email: hittajsc@hitta.vn

Related solutions: