To ensure smooth and comfortable elevator operation, installation factors need to be carefully considered. Firstly, when selecting elevator equipment, it’s important to choose high-quality machinery and good vibration damping devices to minimize noise.

Within the machine room, noise is mainly generated by the characteristic sound of elevator equipment. To reduce this noise, it’s necessary to choose elevator motors of good quality to reduce noise sources and ensure precision in machining core steel parts, brakes, gears, and connecting accessories.

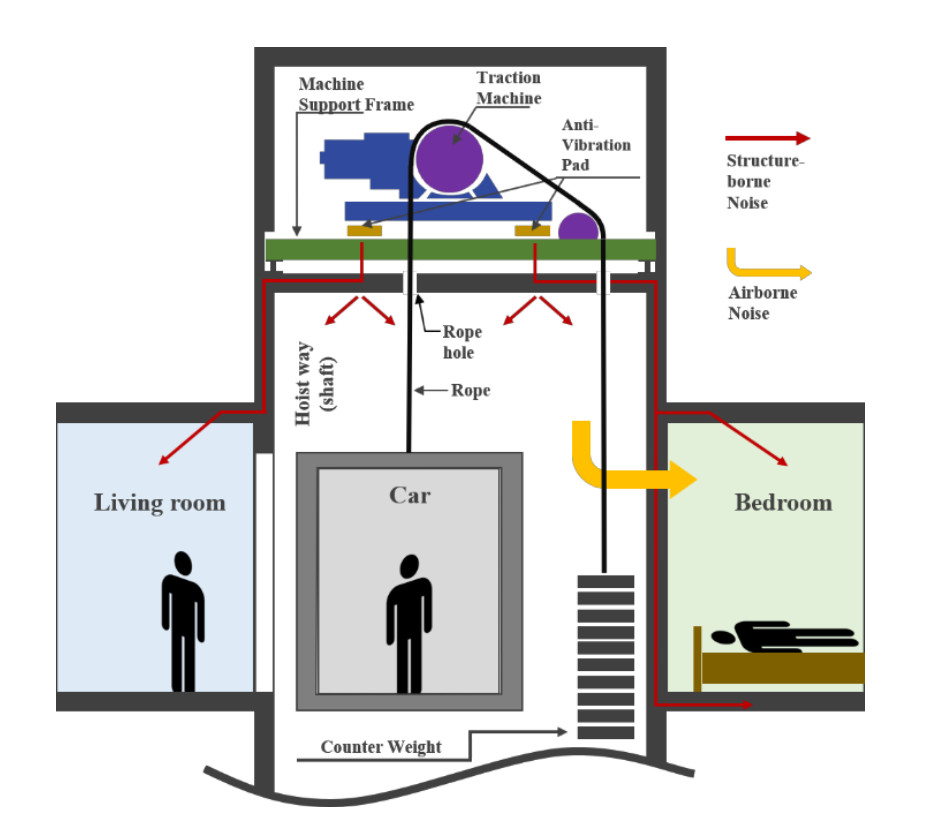

Issues of noise and vibration transmission through structures and air are classified in the elevator machine room and shaft areas, based on which, construction and installation solutions are divided into controlling vibration along with noise sources and transmission control.

Installation & construction of noise-restricted elevators

| Description | Noise Source | Solution |

|---|---|---|

| Structural Noise | Machine Room | Solutions for vibration sources: – Use high-quality motors. – Precisely balance brakes, gears, and elevator. |

| Vibration control measures: – Isolate the traction machine from the frame. – Isolate the equipment cabinet from the machine room panel. | ||

| Hoistway, Elevator Shaft | Vibration Source | Solutions for vibration sources: – Improve the accuracy of guide rail processing: Processing error within ±2 mm/5 m range. – Improve guide rail installation accuracy: Surface mismatch between guide rails within ±0.05 mm range. |

| Vibration control measures: – Clamp the guide rails at the edge of the base. – Isolate guide rails with the compartment of the hoistway, elevator cage. | ||

| Airborne Noise | Machine Room | Solutions for noise sources: – Use high-quality motors. – Precisely machine brakes, gears, and coupling components. – Use low-noise cooling fans or self-cooling systems. |

| Noise reduction measures: – Install soundproofing covers through cable ducts. – Soundproof airborne noise in the machine room. | ||

| Hoistway, Elevator Shaft | – Elevator doors are installed accurately for smooth operation. – Adjust the volume of the door annunciator. |

The table above displays construction solutions to minimize noise and vibration during elevator operation, compiled through years of research by Hitta after reviewing various research documents.

Noise transmitted through structures is often generated in the machine room, primarily through the vibration of the lifting machine. To minimize this noise, it’s necessary to use lifting machine motors with high-quality power filters and to install brakes, gears, and elevators to maintain the precise balance of the lifting machine.

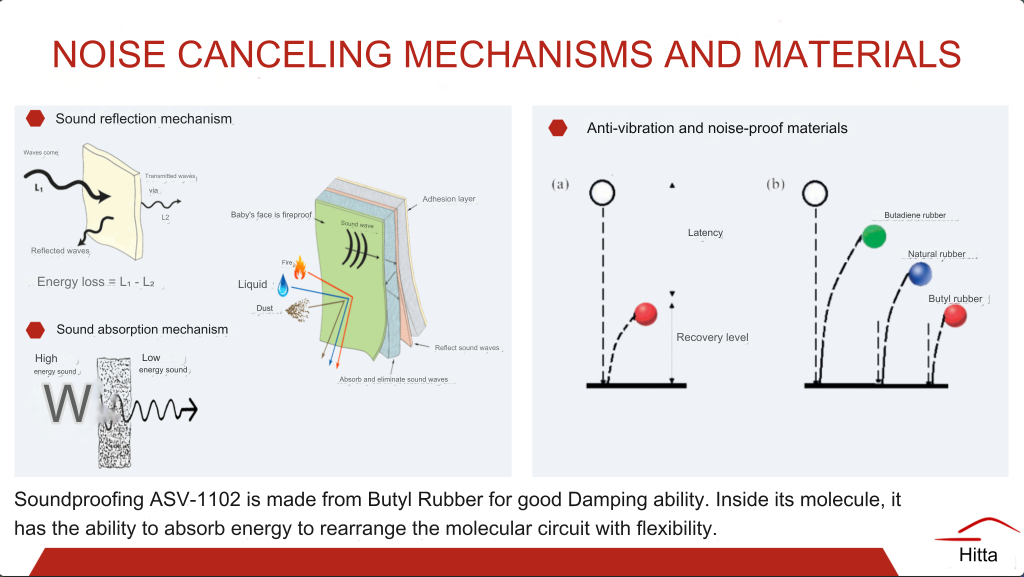

Furthermore, high-performance soundproofing pads such as neoprene or rubber should be placed at fixed points so that the vibrations generated are retained within the traction machine and control cabinet. When installing vibration damping pads on the traction machine, the first natural vibration frequency of the entire elevator system should be maintained in the inaudible frequency range.

To ensure the accurate operation of the traction machine with the height between the elevator and the landing floor, it’s necessary to install the lifting machine and vibration damping pads, maintain balance to minimize isolation deviation. To achieve this, close cooperation with the elevator manufacturer and installer is required during the installation phase.

To reduce noise transmitted through the structure generated in the corridor or elevator shaft, the machining error of the guide rails must be maintained within ± 2 mm / 5 m and the surface difference between the connecting rails must be installed within ± 0.05 mm, reducing vibration from roller motion.

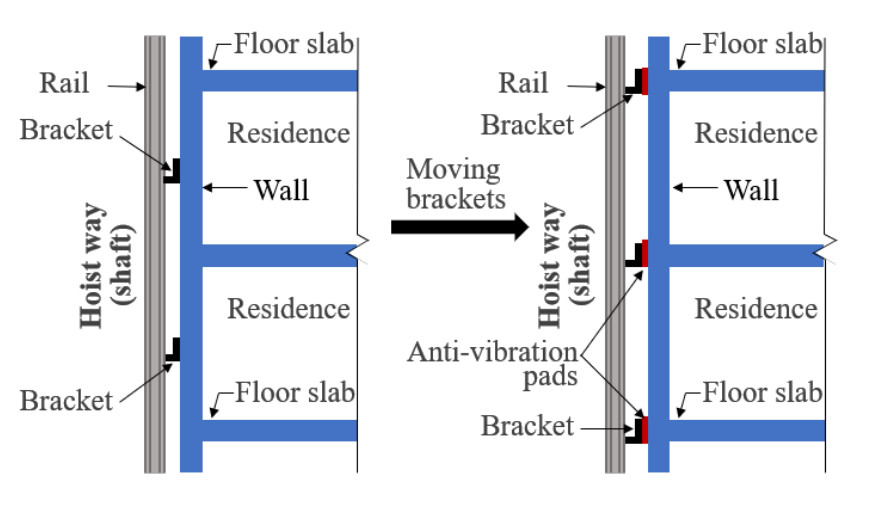

Noise transmitted through vibration generated in the corridor or elevator shaft occurs between the rollers and the guide rails of the cabin. To prevent this, support brackets need to be installed alongside the floor surface to keep the guide rails fixed.

The hinge edges of the floor plate are stiffer than the walls of the elevator shaft and will limit the transmission of interaction between the guide rails and rollers from creating noise transmitted through the structure in the adjacent space. Moreover, vibration damping pads should be installed between the support brackets and the edge of the floor plate. According to reference, depending on the position of the rail support, there is an average noise difference of about 4 dB due to sound measurement while the elevator is operating.

To minimize noise during elevator operation, consider measures related to the construction and installation phases, as airborne noise generated in the machine room is mainly frequency sound. Choosing a good quality motor to deal with noise sources and precise design, as well as manufacturing brakes, gearboxes, and connecting components, are crucial.

Adding additional soundproofing layers

Using low-noise cooling fans or a self-cooling system in the machine room is necessary. Installing soundproofing materials around the suspension holes also helps reduce noise transmitted through the air in the machine room. Then, use soundproofing materials to reduce noise on the walls and ceiling in the machine room.

After placing 50mm thick glass wool on the walls and ceiling in the machine room, the noise level was reduced by an average of about 6.2 dB confirmed. Particularly, the noise level in the frequency range of 1 kHz was reduced by a maximum of 9.4 dB. The noise in the corridor or elevator shaft is mainly related to the elevator doors. The main source of door noise is misalignment or incorrect installation and floor-level alarms. To address these issues, accurate installation of the doors and adjustment of the alarm volume to <60 dB(A) are required.

Specialized soundproofing material for elevators

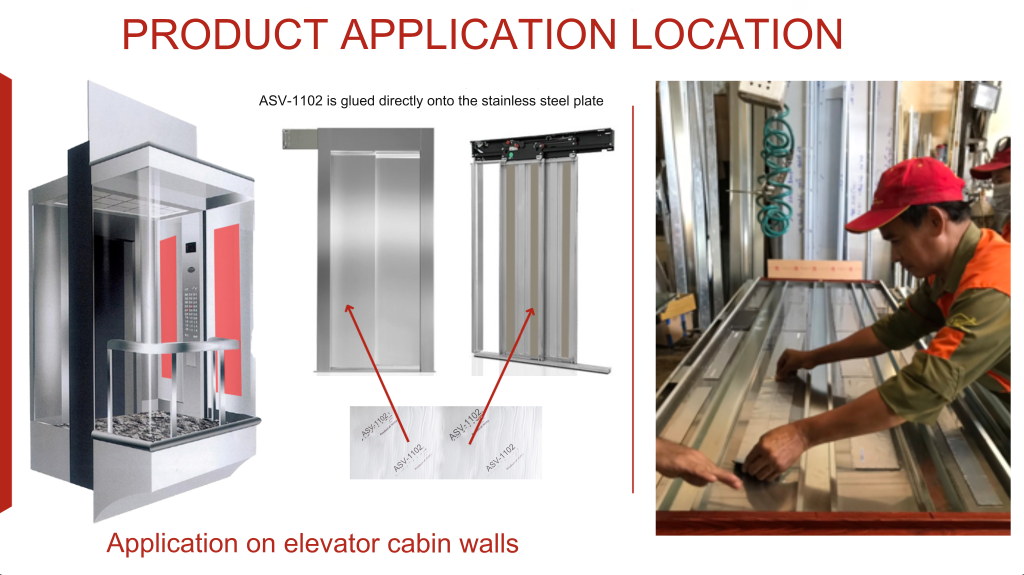

The ASV-1102 Damping-tape product is a self-adhesive modified Butyl rubber material. It adheres well to various surfaces and functions to absorb and dampen vibrations and noise, especially those with medium and high frequencies that cause discomfort for people inside the elevator cabin.

The mechanism of the ASV-1102 Damping-tape material involves damping sound and vibrations through its special adhesive and polymer matrix, absorbing energy from both sound and vibrations due to its porous structure.

- Absorption of impacts/vibrations.

- Substantial shock reduction.

- Dampening vibrations from other components into the elevator cabin.

- Excellent resistance to wear and aging.

- Fills in gaps between different surfaces coming into contact, reducing vibrations.

- Adheres to uneven surfaces seamlessly.

- Soft, flexible, extremely easy to install.

Advantages of ASV

High aesthetic appeal: The nearly invisible bonding creates a smooth surface without protrusions or indentations.

Excellent adhesion of Hitta ASV-1102 noise and vibration damping helps create conditions and aids in dampening sound and vibration. Poor adhesion can lead to peeling, air bubbles, and water bubbles, causing water to seep inside and gradually corrode elevator components. Hitta ASV-1102 has been proven not only through standard tests but also demonstrated quality through the trust of users as well as leading elevator manufacturing and installation companies in Vietnam.

High heat resistance: Poor heat resistance can cause the insulation layer to melt, affecting surrounding components and areas, and creating an unbearable odor that directly impacts the health of elevator passengers. Hitta ASV-1102 automotive soundproofing with a heat resistance of up to 150°C ensures the prevention of adhesive melting, unpleasant odors, and ensures effective noise and vibration reduction.

RoHS (Restriction of Hazardous Substances Directive) is the highest safety standard ensuring that Hitta ASV-1102 automotive soundproofing materials are completely safe and do not contain any harmful substances that could affect user health.

Easy installation: ASV-1102 elevator noise and vibration damping properties are soft and flexible, making them very convenient for elevator manufacturing and construction companies, as they are simple to remove and apply, without the need for cutting, drying, or other complex construction measures. This helps construction companies shorten implementation time and reduce technical costs for a noise and vibration damping package.

Cost savings: Price, alongside effectiveness, is a top priority when choosing any solution. ASV-1102 combines reinforced adhesive tape all in one solution for elevator noise and vibration damping without requiring any additional solutions or requirements. With ASV-1102 offering extremely competitive prices on the market, Hitta’s noise and vibration damping solution for elevators will save customers a significant amount of budget.

Contact Information

Hitta JSC is the leading supplier of noise and vibration damping products and solutions in Vietnam, renowned for its Hitta brand products. We have successfully provided solutions for elevators and various high-end vehicles such as buses, tourist cars, and limousines. Hitta’s noise and vibration damping products are trusted by hundreds of units nationwide, and this number continues to grow. Contact us today for consultation.

- ☎️ Hotline: 090.8611.011

- ✉️ Email: hittajsc@hitta.vn