Polystyrene (PS) is one of the most commonly used thermoplastics worldwide. It is a cost-effective plastic per unit weight, easily moldable into sheets, foam, and films, thus widely used in protective packaging applications.

Due to the material properties and multi-industry applications of Polystyrene, adhering this material poses many challenges in bonding it with other materials. Let’s explore the commercial types of Polystyrene with Hitta.

XPS/Styrofoam

Styrofoam is an extremely lightweight, thermoplastic material with the ability to absorb force and impact, appearing as a solid foam at room temperature. XPS possesses these qualities in part due to 90% of its composition being air. When in a molten state at its melting point, the material becomes highly malleable, allowing it to be formed into various shapes and patterns. It is also an excellent insulator, ideal for packaging materials and crafts.

The name Styrofoam™ is commonly but inaccurately used to refer to EPS, Expanded Polystyrene, a rigid foam, serving as a substitute for XPS. Similarly, EPS is used for thermal insulation purposes in walls, roofs, and foundations.

GPPS (General Purpose Polystyrene)

GPPS is a completely transparent, rigid, and odorless solid product. Typically, trays and refrigerator boxes are made from GPPS, as well as tape cases and CD discs. However, it can also be produced in the form of pellets sized 2-5mm. It has good heat resistance and can withstand various types of oils and corrosive chemicals.

HIPS (High Impact Polystyrene)

HIPS typically contains 5-10% rubber and therefore has high tear and impact resistance as well as durability. HIPS sheets and rolls are easily manufactured for use in printing and shaping applications. They are particularly suitable for lithographic printing or flexible screen printing, in addition to food and medical packaging, due to compliance with specific regulations.

Key Properties of Polystyrene

- Surface energy: 41 mJ/m².

- Maximum temperature: 65°C.

- Softening temperature: 107°C.

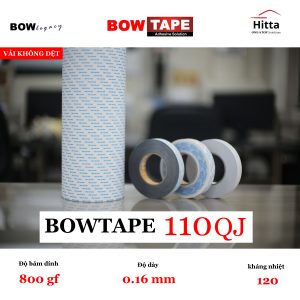

Polystyrene Adhesive Tape

- Dán nhựa Polypropylene PP & Polyethylene PE

- Băng keo dán Acetal (Polyoxymethylene)

- Băng keo dán nhựa TPO

- Băng keo dán nhựa bề mặt năng lượng thấp (LSE)

- Băng keo dán nhựa EVA (Ethylene Vinyl Acetate)

Hitta’s specialized industrial adhesive tape solutions for bonding low-energy surface plastics in general and polystyrene plastics in particular. Depending on the application and business process, Hitta offers various types of tapes tailored to meet any customer requirements, replacing other solutions with advantages such as:

- Bonding without the need for primers on difficult-to-bond substrates.

- Resistant to various oils and corrosive chemicals.

- Increased speed and productivity.

- Reduced chemical usage for improved safety.

- Providing long-lasting and reliable durability.

- Enhancing design flexibility.

- Ensuring no harmful chemicals (for medical and food applications).

- Reducing production costs.

Contact us

Hitta specializes in providing various specialized adhesive tapes for both industrial and commercial sectors. Contact us for advice on the most effective solutions at the lowest cost.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn

Products: