HMPUR HHD 6009 Born2Bond™

HHD 6009 is a one-component, solvent-free, moisture-curing hot melt polyurethane adhesive. Upon application, the adhesive reacts with the surrounding moisture or water content of the substrate to form a thermoset cross-linked adhesive.

- Curing by moisture.

- Viscosity: 3500 @110ºC.

- Low application temperature (100°C – 120°C).

- Open time: 2 – 5 minutes.

- Off-white color.

- Excellent adhesion to various substrates including glass and metal.

- Good flexibility.

- High thermal stability.

- Accurate metering.

- Balanced between strength and elasticity.

- Good chemical resistance.

- Resistant to sweat and sebum.

Applications

HHD 6009 is specially designed for assembling electronic devices and can bond to various substrates such as PC, ABS, aluminum, glass, etc.

Application Method

Born2bond HMPUR solutions cover a wide range of viscosities, providing flexibility in choosing processing methods. HHD 6009 can be applied by spray, bead, spiral, or mist. The typical application temperature range is 100-130°C.

Usage Instructions

1. Remove the aluminum vacuum bag just before use.

2. Preheat the dispensing nozzle at the recommended temperature if necessary.

3. Remove the end cap and outer layer on the adhesive surface.

4. Connect the nozzle adapter.

5. Remove any caps or blocks at the nozzle end.

6. Select the appropriate needle and attach it to the tip of standard air distribution units.

7. Insert the dispensing nozzle into the heated part, ensuring the adhesive is heated to the recommended application temperature.

8. Clean a small amount of adhesive.

9. Apply a sufficient amount of adhesive to a clean surface (free from oil, dust, mold release agents, etc.).

10. Bond substrates within the open time of the adhesive.

11. Press and hold the joints firmly to allow the adhesive to reach sufficient strength.

Storage

HHD 6009 can be stored for up to 6 months in its original packaging, unopened, in a dry place at temperatures ranging from +15°C to +25°C. It should be used immediately after opening the container. Seal the containers tightly to minimize contamination.

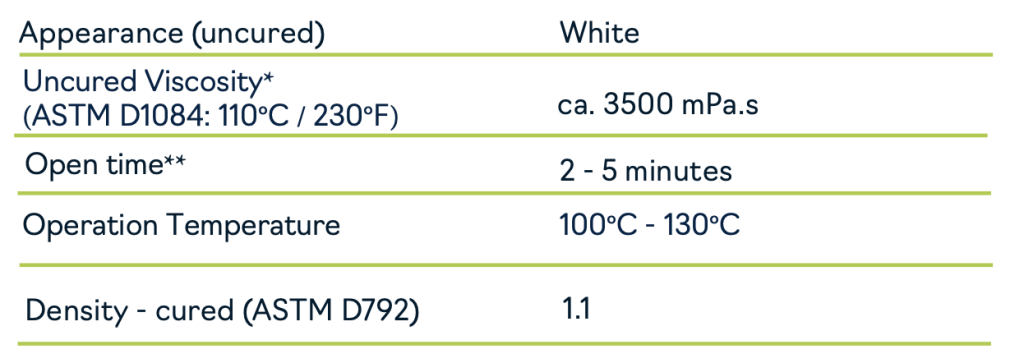

Product Characteristics

*based on Brookfield viscometer

**Open time is an application parameter that depends on the environment temperature, substrates and application process.

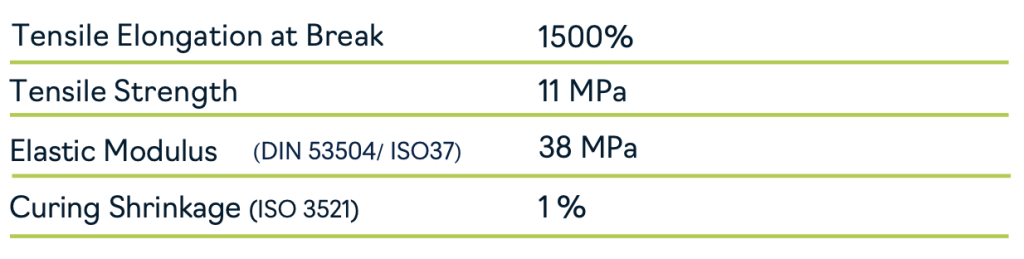

TYPICAL PERFORMANCE OF CURED MATERIAL

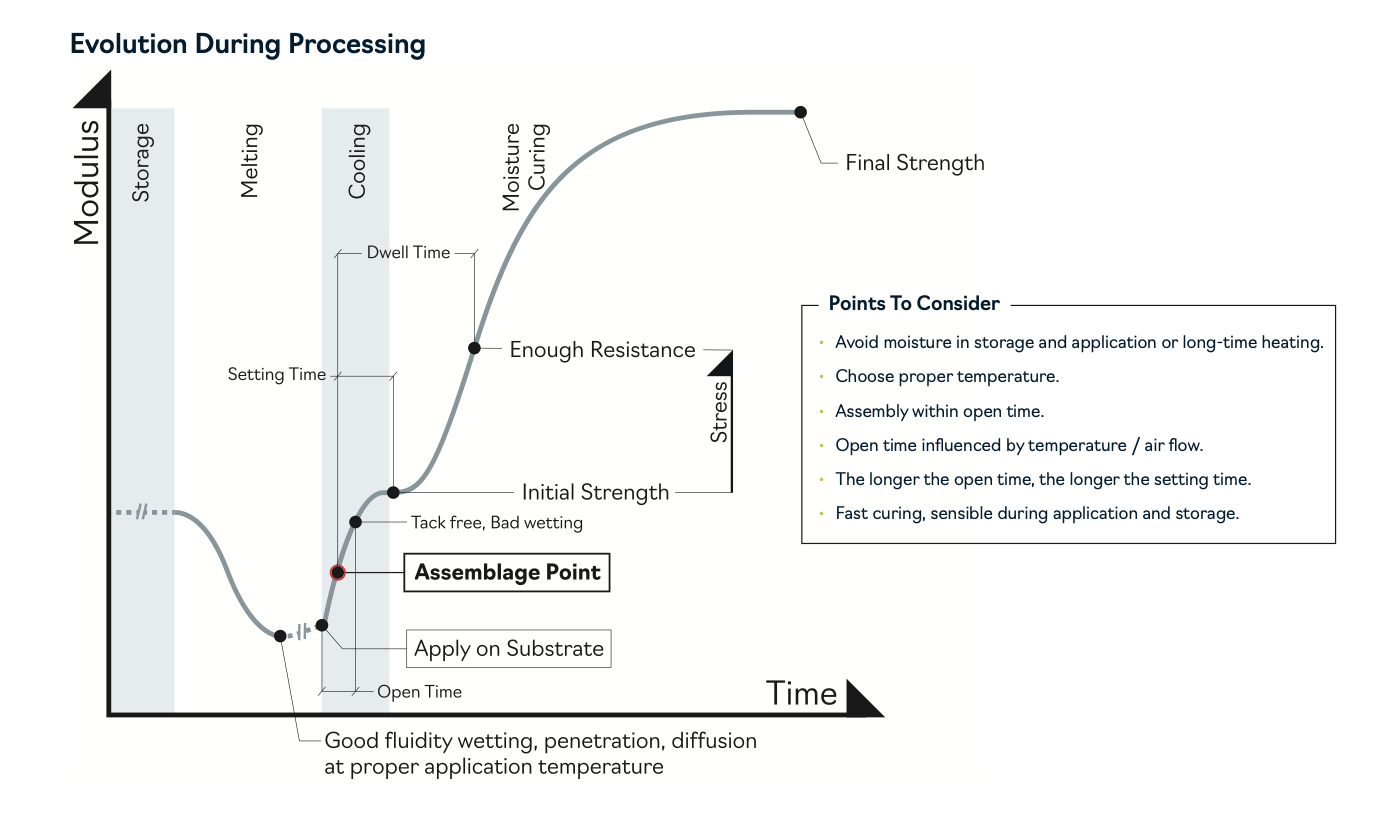

The processing speed depends on the type of substrate, moisture content, and ambient environmental conditions. HHD 6009 will develop adhesive properties within 24 hours. However, optimal properties are achieved after three to seven days at room temperature.

For all performance data provided in this Technical Data Sheet (TDS), samples are prepared as follows: A bead of adhesive with dimensions of 1.5 mm*2 mm is applied from one PC to another using a 0.12 mm thick spacer. A 1 kg weight is applied to the sample for 20 seconds, after which the sample is processed for 3 days at 23°C/50%RH before testing. Testing is conducted at a speed of 2 mm/min.

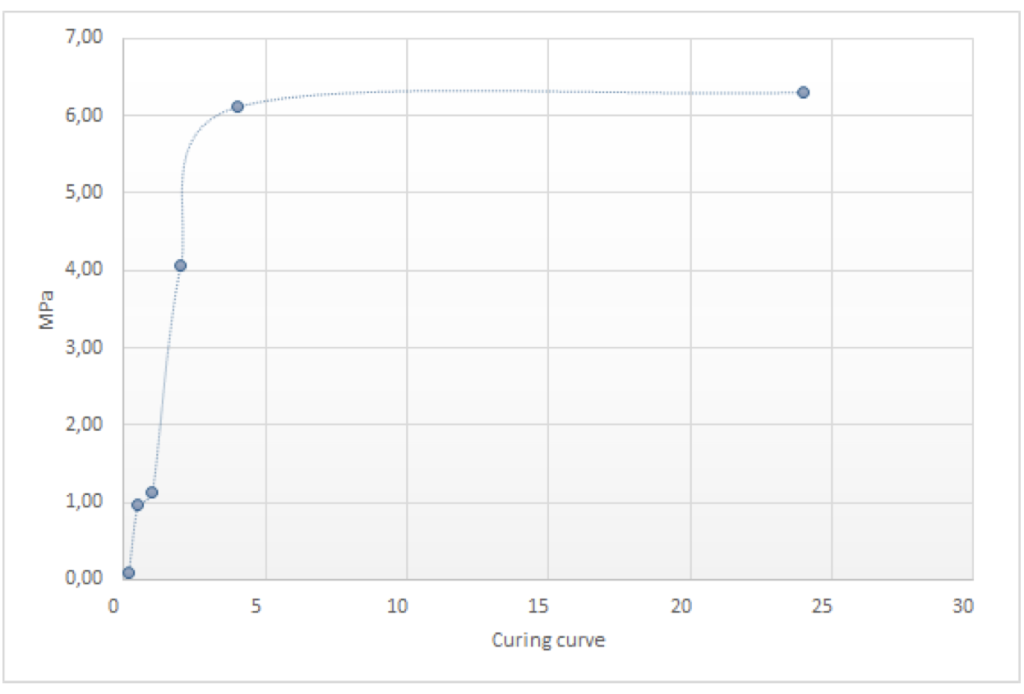

CURING SPEED

“Sample Preparation and Testing Conditions: A bead of adhesive with dimensions of 1.5 mm*2 mm is applied from one PC to another using a 0.12 mm thick spacer. A 1 kg weight is applied to the sample for 20 seconds, after which the sample is processed for 7 days at 23°C/50%RH. Testing is conducted at a speed of 2 mm/min.”

CURED PHYSICAL PROPERTIES

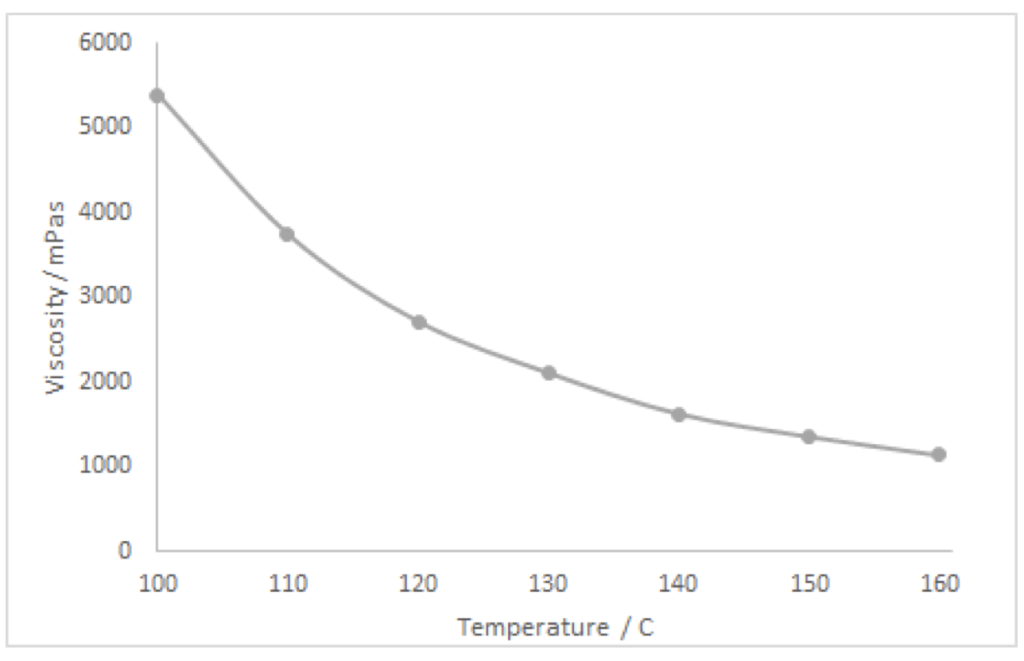

APPLICATION PROCESS – VISCOSITY

Testing method: Brookfield, spindle 27 @ 20rpm, 27°C @ 60% RH, 11.6g sample, unloaded run for 30 minutes at each temperature.

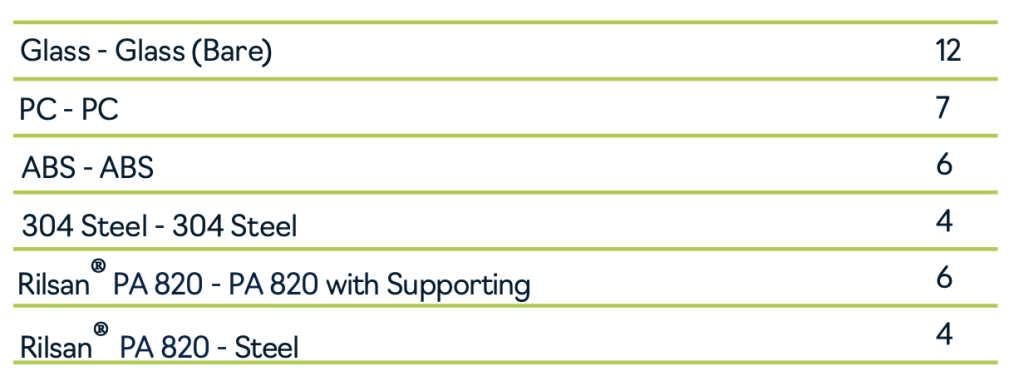

BONDING PERFORMANCE

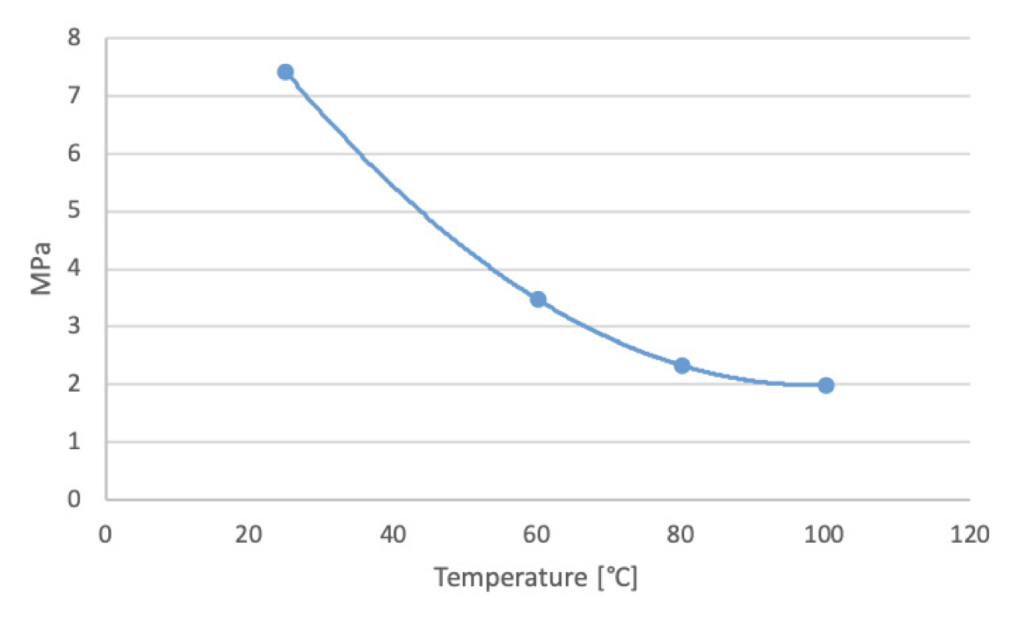

HOT STRENGTH

Sample preparation and testing conditions: A bead of adhesive with dimensions of 1.5mm*2mm is applied from one PC to another using a 0.12mm spacer. A weight of 1kg is applied to the sample for 20 seconds, then the sample is processed for 7 days at 23°C/50%RH. Testing is performed at a speed of 2mm/minute after exposure to heat for 5 minutes in the chamber.

SEBUM AND SWEAT RESISTANCE

Sample preparation and testing conditions: A bead of adhesive with dimensions of 1.5mm*2mm is applied from one PC to another using a 0.12mm spacer. A weight of 1kg is applied to the sample for 20 seconds, then the sample is processed for 3 days at 23°C/50%RH before being immersed in grease and sweat at 45°C for 7 days. Testing is performed at a speed of 2mm/minute.

- Before: 7.5.

- After sweat: 7.

- After sebum: 3.8.

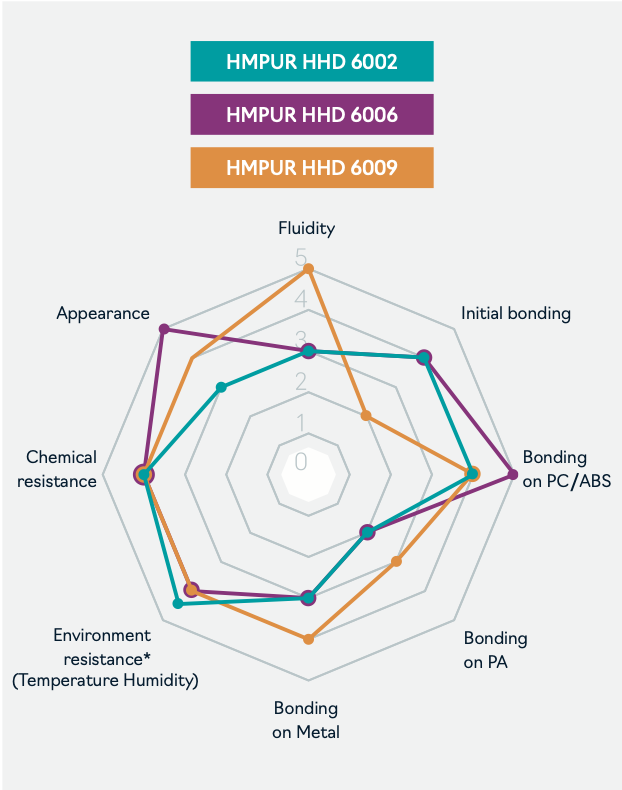

Born2Bond™ HMPUR HDD Series

Born2Bond™ HMPUR HHD (Hot Melt Polyurethane Reactive) adhesives, such as HHD 6002/6006/6009, from Bostik, are versatile one-component solutions capable of bonding various substrate types. With different viscosities and open times, they allow precise application across different assembly applications and processes.

Guide to selecting HMPUR HHD 6002/6006/6009 adhesives:

With excellent bonding performance (both hardness and elasticity), high-performance HMPUR adhesives withstand temperature and humidity fluctuations. They also resist impact, thermal shock, and various chemical and organic compounds, including sweat and oils—making them ideal for use in handheld devices and wearable electronics.

Advantages of the Born2Bond™ HMPUR HDD series:

- Moisture-curing.

- Adheres to various substrates.

- Suitable for multiple application methods.

- Balances strength and elasticity well.

- Adheres to multiple substrates.

- Low application temperature.

- Good resistance to temperature, humidity, and chemicals.

- Single-component solution.

Identifying corresponding application methods:

Born2Bond HMPUR solutions span various viscosity levels, offering flexibility in application method selection:

- Low-viscosity products can be dispensed in bead form.

- High-viscosity products allow for pellet application.

- Some products can be applied using all three methods.

Identifying process requirements:

While the suggested application temperature for Bostik’s HMPUR solutions is generally similar (typically between 110°C – 130°C), other process parameters can also guide product selection. These include:

- High-throughput production lines may require products with high initial strength.

- Other processes may require extended processing windows to position components before adhesive bonding.

- Bostik’s HMPUR solutions encompass various considerations during the processing stage.

Meeting performance requirements:

Substrate adhesion is a primary concern. Some Bostik HMPUR products excel more than others in adhering to low-energy substrates. For example:

- Polyurethane adhesives, once cured, typically exhibit good resistance to chemicals, solvents, and water. Bostik’s HMPUR product line offers varying degrees of resistance to these conditions.

- Polyurethane adhesives can create rigid bonds or bonds with more elastic properties.