HMPUR (hot-melt polyurethane reactive) adhesive is a high-performance adhesive type specifically applied in the field of electronic devices, where precision, durability, and application speed are crucial.

Table of Content

Outstanding features of HMPUR adhesive

At room temperature, HMPUR adhesive exists in a solid state, similar to other hot melt adhesives such as thermoplastic polymers like ethylene vinylacetate (EVA), polyalphaolefin (PAO), polyester, and polyamide.

The application temperature range varies from 85°C to 140°C, lower than the temperatures required for conventional thermoplastic hot melt products. The viscosity at application temperature can be tailored within the range of 2,000 to 60,000 cPs depending on specific requirements.

HMPUR adhesives are manufactured with open times ranging from a few seconds to several minutes to meet application and production needs.

The unique characteristic of HMPUR adhesive that sets it apart from conventional hot melt adhesives is its ability to cure into a thermosetting solid material that is resistant to melting. This curing process involves reacting with moisture in the air or in typical substrates to create durable, heat-resistant bonding materials.

Advantages of HMPUR adhesive

The advantages of HMPUR adhesive stem from the described characteristics above. Some of these advantages include:

- Excellent heat and environmental resistance after curing. Many types of HMPUR adhesives can withstand temperatures ranging from -40°C to +93°C while maintaining strong bonds.

- Minimized fixation due to controlled curing time. HMPUR can be applied through spraying, bead, swirl, and misting methods. The final curing process and ultimate strength are achieved within a few hours to several days depending on the adhesive, substrate, and environmental conditions.

- HMPUR adhesive can be designed and developed with various properties for specific applications.

- HMPUR adhesive is 100% solid and therefore does not contain volatile organic compounds (VOCs) and does not require drying. This helps alleviate many environmental concerns associated with solvent-based adhesive and the energy demand for drying water-based and solvent-based products.

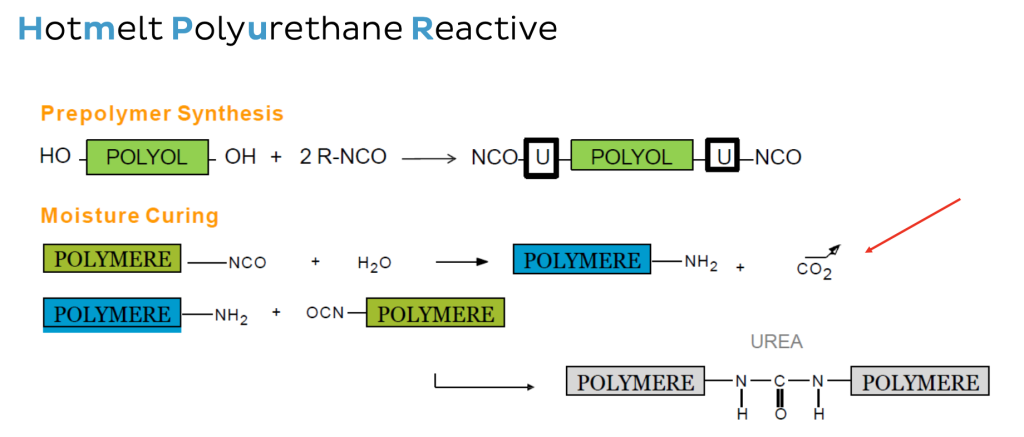

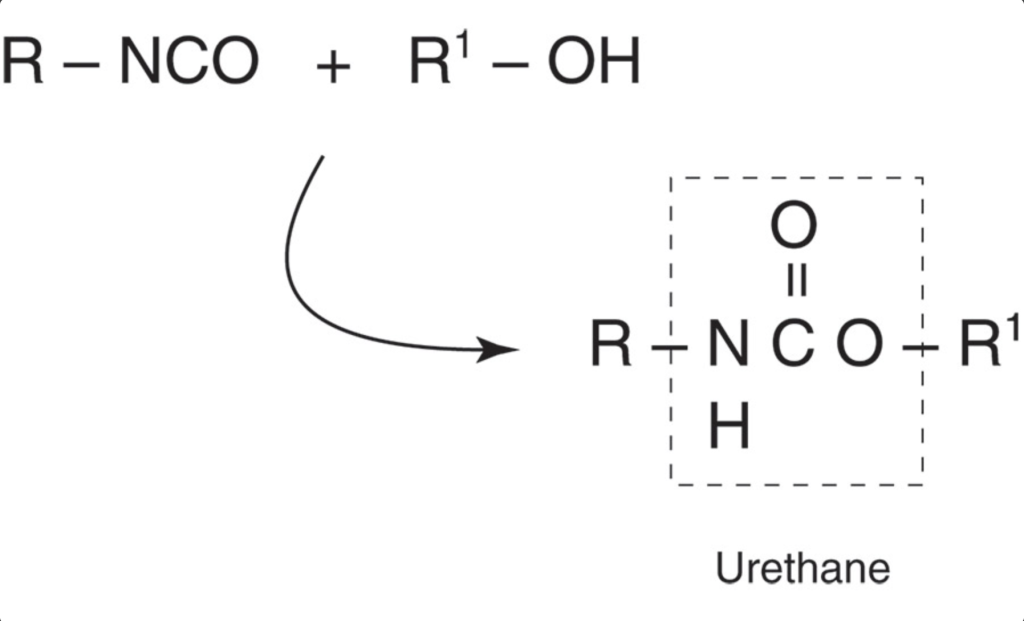

The HMPUR adhesive is manufactured by reacting a mixture of polyol with excess diisocyanate. The reaction of the isocyanate (-NCO) group with the alcohol (-OH) group forms the urethane group, as depicted in the diagram below.

How is HMPUR adhesive made?

Having an excess amount of diisocyanate means that the molecular weight of the resulting product is not excessively high, and the viscosity of the HMPUR product can be controlled.

These adhesives are then transferred from the reaction vessel to storage drums in a molten state. The storage drums are sealed tightly to prevent exposure to moisture from the air while the adhesive solidifies upon cooling.

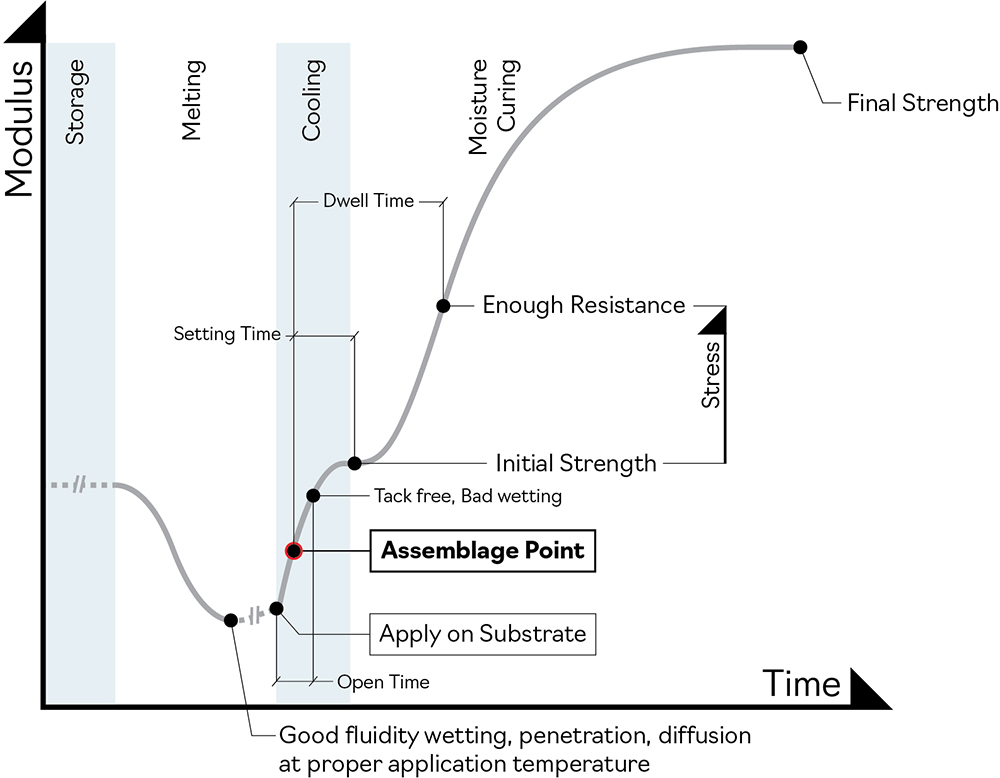

How HMPUR works?

The adhesive is melted using specially designed melting equipment and then applied to the products that need to be bonded.

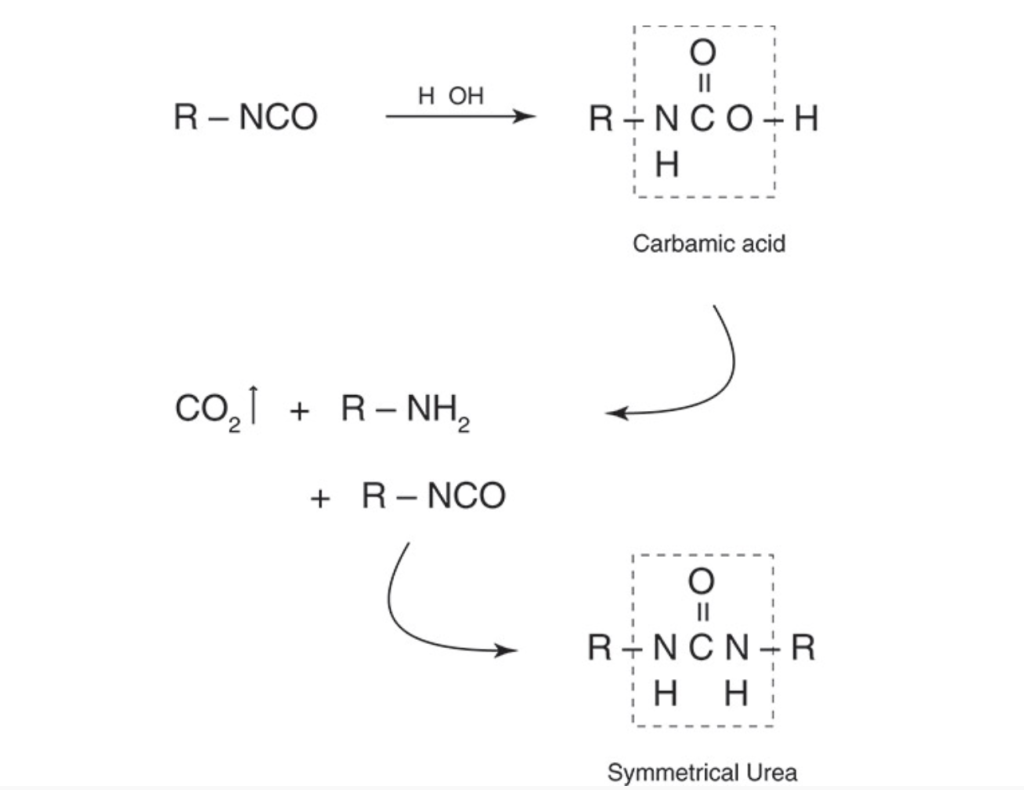

Within a few hours or days following application, the reaction described below takes place.

Curing reaction of HMPUR

This reaction of isocyanate with water forms a highly stable polyurea structure, providing HMPUR with thermal resistance and environmental performance. The cross-linked polyurea structure effectively bonds with the adhesive to prevent melting or dissolving, distinguishing it from standard hot melt adhesives.

Specific properties required for various applications are integrated into HMPUR adhesive by using multiple types of polyols, isocyanates, and additives. Polyols are used to modify open time, curing time, and wetting ability of different surfaces effectively to create efficient bonds.

Applications of HMPUR

Advancements in process and miniaturization manufacturing trends have made HMPUR adhesive solutions more crucial than ever. This is particularly true in the electronics industry, where precision, durability, and application speed are paramount.

Specific applications include:

HMPUR adhesive for touchscreen assembly.

Touchscreen assembly: meets the requirement for bonding narrow bezels. Applicable to various substrates (PC/PBT/PA). Fast application. Re-workability.

Application of HMPUR adhesive for bonding ultra-small speakers.

Application of HMPUR adhesive for speaker bonding

Speaker, audio device bonding: bio-based HMPUR. Non-harmful to substrates, does not affect substrate performance. Optimal performance solution for speakers, audio devices compared to ultrasonic welding method.

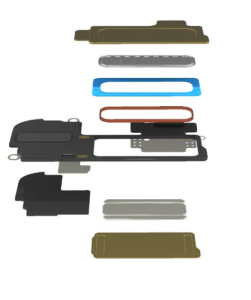

Application of HMPUR adhesive for bonding small detailed structures.

The application demands bonding of intricate and small structures that only HMPUR adhesive can fulfill.

Structural bonding: bonding small decorative edges, attaching battery covers, rear composite casings, ultra-small camera bonding, infrared light bonding, vent hole sealing, heat dissipation.

Bostik’s high-performance Born2Bond HMPUR adhesive

The leading HMPUR adhesive solution, currently, is the Born2Bond series by Bostik, specialized for bonding small and ultra-small electronic devices and components, with the following advantages:

❖ Single component: No mixing required.

❖ Available in various viscosities for selection.

❖ Available in multiple colors: white, off-white, yellow.

❖ Different application temperatures.

❖ Different open times.

❖ Solvent-free: Low or no VOCs.

❖ Moisture-curing: No additional curing equipment required.

❖ Storage and transportation at room temperature.

❖ Suitable for bonding various substrates.

❖ Excellent chemical resistance and aging resistance.

❖ High flexibility and durability, with balanced bonding strength and good impact resistance.

- Bostik’s high-performance Born2Bond HMPUR adhesive is specially designed for application through spraying, beading, swirling, and misting methods.

- It ensures high production efficiency with reduced overall costs.

- It exhibits excellent resistance to moisture, oils, temperature, and impact.

- HHD6002 and HHD6009 meet ISO10993 standards.

Guide to selecting HMPUR adhesive

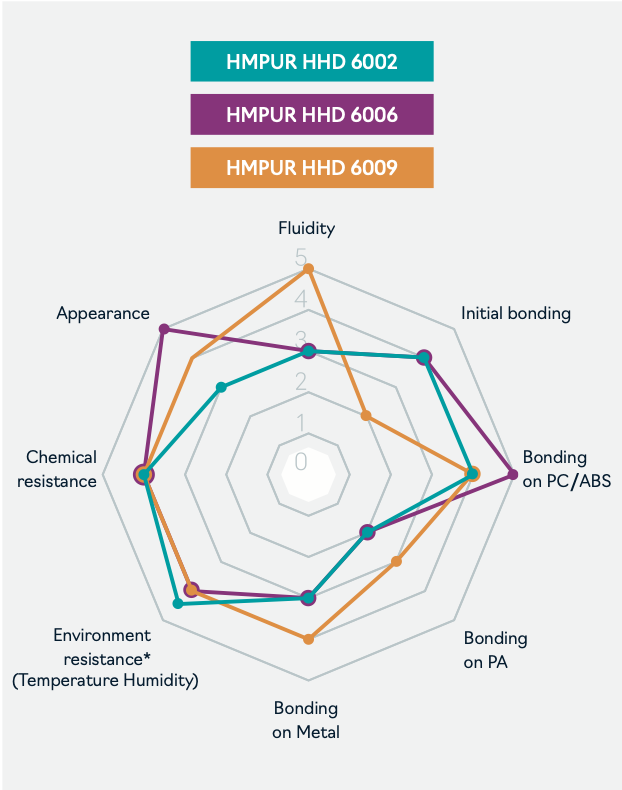

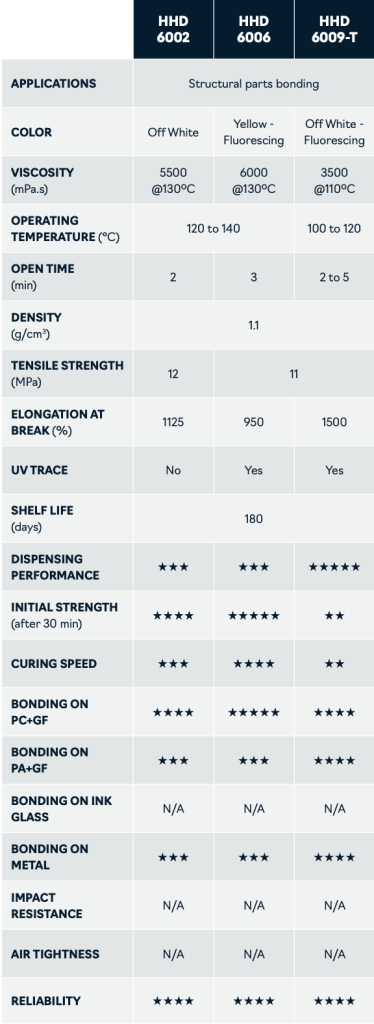

The top 3 HMPUR adhesives currently are HHD6002, HHD6006, HHD6009. To select the suitable HMPUR adhesive, consider the following factors:

- Bonding strength with required substrates.

- Resistance to physical and chemical properties.

- Viscosity.

- Ability to create initial bonding strength.

- Adhesive color.

Guide graph for selecting HHD6002, HHD6006, HHD6009 adhesives

Delivering excellent bonding performance (both hardness and elasticity), Bostik’s high-performance HMPUR adhesives withstand temperature and humidity fluctuations. They also resist impact, thermal shock, and various chemical and organic compounds, including sweat and oils—making this adhesive line ideal for use in handheld devices and wearable electronics.

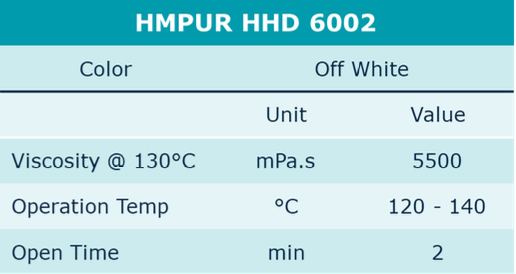

MPUR HHD 6002:

HMPUR HHD 6002 properties

- Strong initial bonding strength.

- Excellent resistance to environmental factors and chemicals.

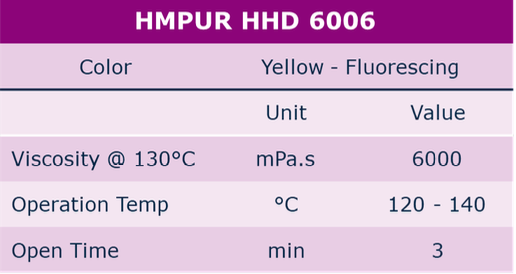

MPUR HHD 6006:

HMPUR HHD 6006 properties

- High bonding capability with plastics, especially PC.

- UV traceability, quality control over distribution.

- High heat resistance.

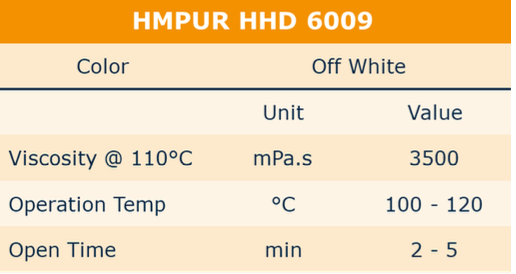

MPUR HHD 6009:

HMPUR HHD 6009 properties

- High bonding capability, especially with metal, glass, PA.

- Excellent fluidity.

- High flexibility.

Comparison table of HMPUR HHD Bostik 6002, 6006, 6009

Guide to selecting HMPUR adhesive application/distribution types

Purchase HMPUR

Hitta specializes in providing specialized glues & tapes for both industry and commerce, contact us for advice on the most effective solution at the lowest cost:

Hitta là Nhà phân phối keo Bostik

- ☎️ Hotline: 0565 33 68 79

- ✉️ Email: hittajsc@hitta.vn