In previous articles, Hitta has discussed the causes of elevator noise and solutions, and factors in installing smooth and comfortable elevator operation to help clients understand the root of elevator noise as well as corresponding solutions. However, the essence of noise lies in frequency, so it’s crucial to understand the frequency range and intensity of noise and vibration sources to effectively address elevator noise issues, as Hitta will present in this article.

Noise Testing Experiment

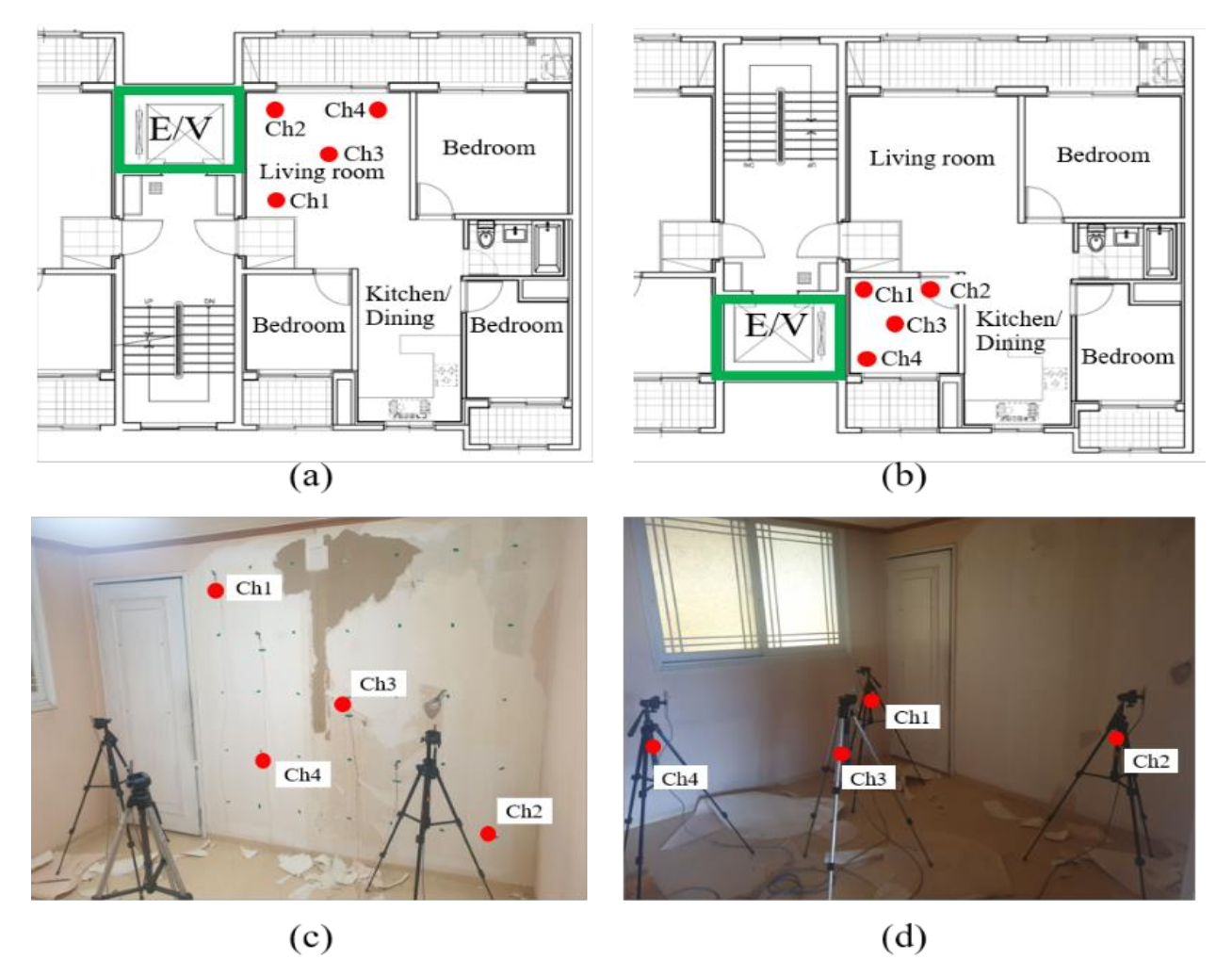

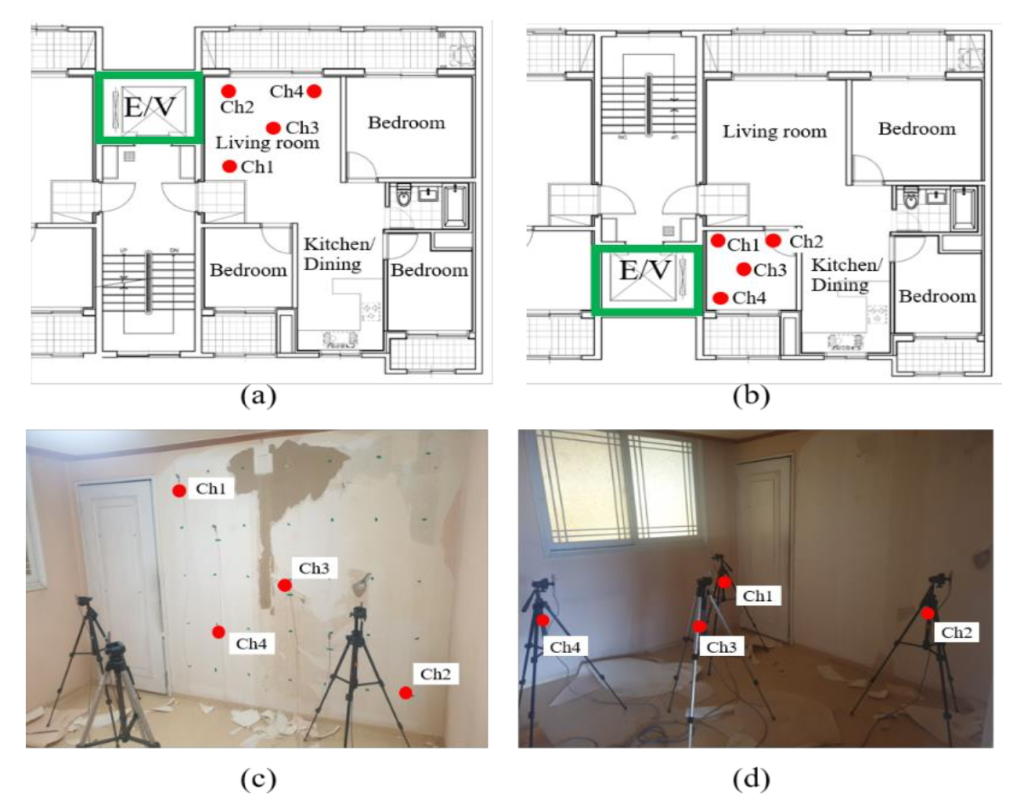

a) Living room in building “A”.

b) Bedroom in building “B”.

c) Vibration measurement sensors on the walls of the living room or bedroom.

d) Noise measurement sensors in the living room or bedroom space.

Below are the specifications of the measuring device:

| Description | Model | Manufacturer | Details |

|---|---|---|---|

| Noise Analyzer | Apollo | SINUS | Bandwidth: DC~80 kHz / Dynamic Range: 120 dB |

| Microphone | CLASS 0 (LEMO) | G.R.A.S | Bandwidth: 3.15~20 kHz / Dynamic Range: 135 dB |

| Vibration Analyzer | SA-01 | RION | Bandwidth: 0.5~20 kHz / Dynamic Range: 140 dB |

| Accelerometer | Single-axis accelerometer | B.S.W.A | Bandwidth: 0.5~14 kHz / Maximum Acceleration: 0.0002 g rms |

The sound measurement result of the elevator in an average residential building is a sound pressure level of 35 dBA. Although this noise level is quieter than the standard sound level of a library, many residents still find it uncomfortable because the low-frequency noise significantly affects them.

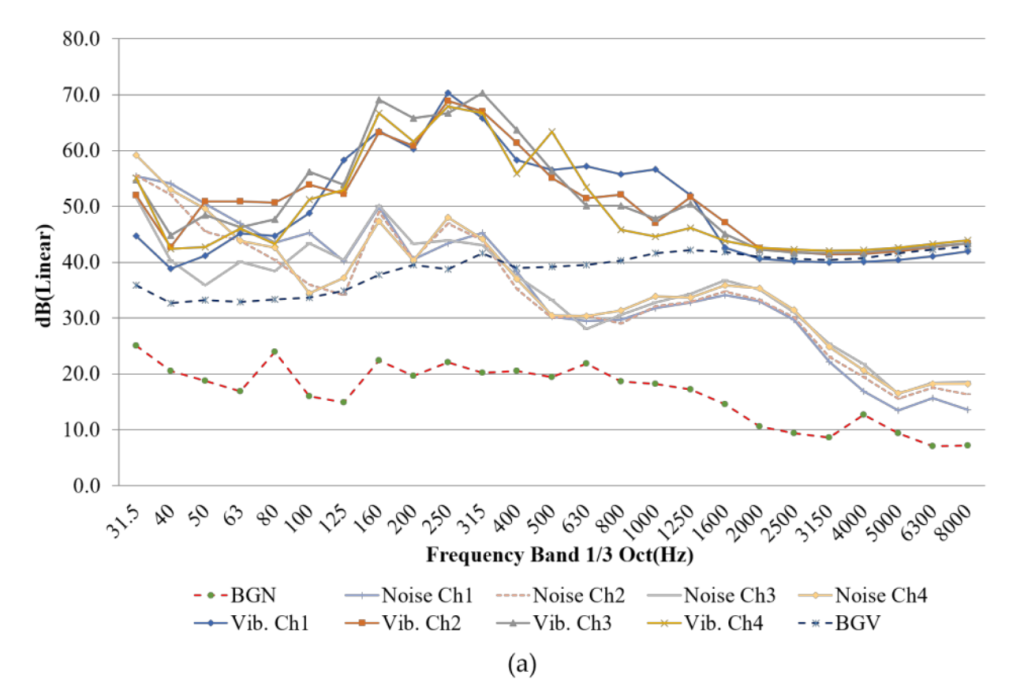

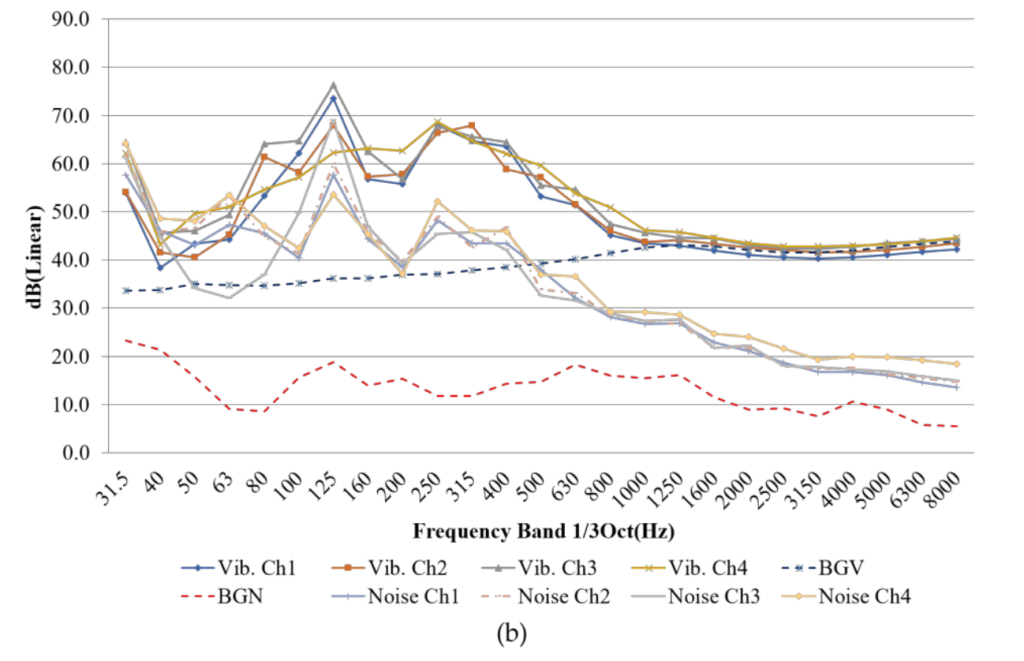

The energy distribution of ambient noise sporadically ranges from 125 Hz to 4 kHz; however, as shown in the results table below, the elevator noise is distributed up to 63 Hz or even up to 32 Hz.

In other words, the noise accompanied by vibrations is perceived as significantly discomforting even at low levels. The general trend identified in both graphs is the increased values of the background noise (abbreviated as BGN) and background vibration (abbreviated as BGV), particularly in the low-frequency range below 500 Hz.

For measurements in the living room, the impact of noise and vibration has affected residents’ comfort. In the living room, this impact is most pronounced in the frequency range of 250 Hz. Additionally, for measurements in the bedroom, the impact is most pronounced in the frequency range of 125 Hz. Similarly, for both noise and vibration, the same trend is confirmed in both the living room and bedroom at the frequency range of 125 Hz. Based on these results, solutions should be proposed in the low-frequency ranges where noise and vibration generated during operation significantly impact residents’ lives, aiming to minimize elevator noise.

Conclusion

- Using specialized frequency measurement devices will detect the low frequencies of noise and vibration that impact the residential area.

- It’s necessary to effectively address both high-frequency noise and vibration, in addition to eliminating noise and vibration at low frequencies.

- Building construction solutions that do not adequately address elevator noise may require additional soundproofing material solutions.

Low-Frequency Noise Reduction Solution for Elevators

- Read more: Giải pháp chống rung chống ồn cho thang máy

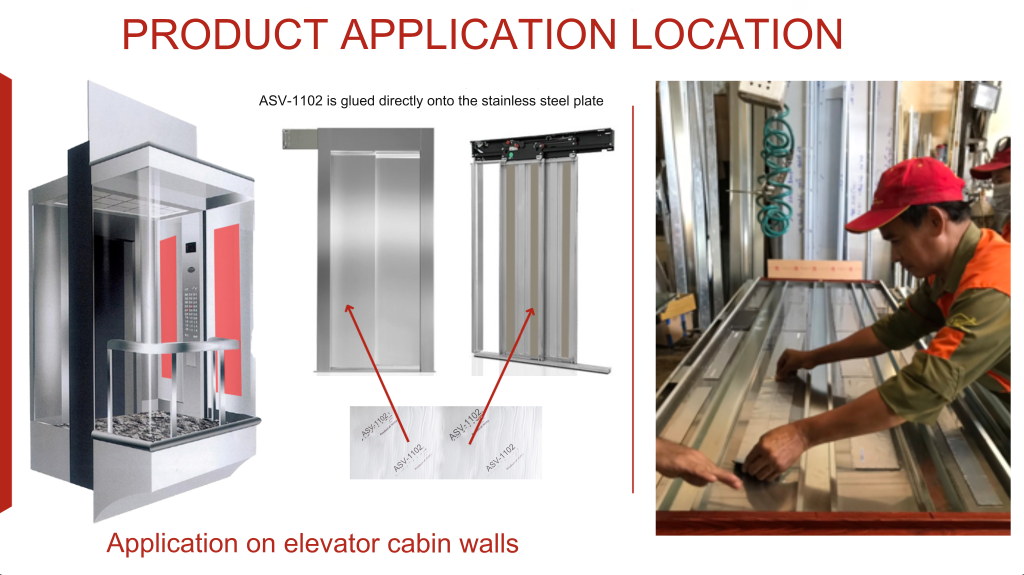

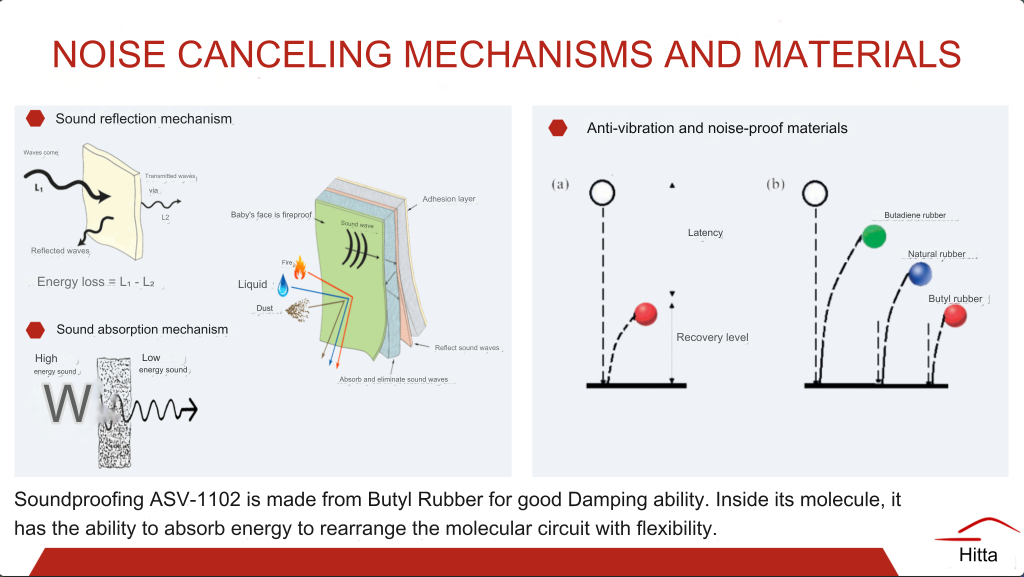

The product for noise and vibration reduction, ASV-1102 Damping-tape, is a specially formulated self-adhesive Butyl rubber material. It adheres well to various surfaces and has the capability to absorb and dampen vibrations and noise across all three frequency ranges – high, medium, and low – making it highly suitable for soundproofing and noise reduction in elevators, particularly in high-rise residential buildings.

The mechanism of ASV-1102 Damping-tape involves damping sound and vibrations through its special adhesive and polymer matrix, absorbing the energy of sound and vibrations due to its porous structure.

- Absorbs impacts/collisions and dampens vibrations.

- Significantly reduces shocks.

- Suppresses vibrations transmitted from other components into the elevator cabin.

- Excellent resistance to wear and aging.

- Fills gaps, preventing different surfaces from contacting each other and causing vibrations.

- Adheres to uneven surfaces and gaps.

- Soft, flexible, and extremely easy to install.

Contact Information

Hitta JSC is the leading provider of noise and vibration control products and solutions in Vietnam, renowned for our Hitta brand products. We have successfully implemented solutions for elevators and various high-end vehicles such as buses, tourist cars, and limousines, among others. Hitta’s noise and vibration control products are trusted by hundreds of clients nationwide, and this number continues to grow. Contact us today for consultation:

- ☎️ Hotline: 090.8611.011

- ✉️ Email: hittajsc@hitta.vn