Separating Elevators from Residential Areas

In residential buildings, two methods are employed during the design phase to mitigate the impact of noise and vibrations from high-rise building elevators on the surrounding environment.

Firstly, sensitive areas such as bedrooms and living rooms are separated from the elevator shaft or elevator tunnel. Secondly, an isolation space is arranged between rooms adjacent to the elevator tunnel to increase the thickness of the concrete layer and the tunnel walls, and additional structural components similar to detailed changes of the elevator tunnel are incorporated.

The most effective method to minimize the impact of noise and vibrations from elevators in high-speed high-rise buildings is to separate the elevators from residential areas.

By comparing the noise measurement results from scenarios where the elevator is adjacent to living rooms or bedrooms, as shown in the figure below, with the noise measurement results when the elevator is separated from residential areas, the effectiveness of this method can be confirmed.

The measurement results have confirmed that the noise is reduced by 10-20 dB in the frequency range above 125 Hz when the elevator is separated from residential areas.

However, in areas with limited construction space, optimizing the design of high-density apartments is necessary. Considering design constraints such as daylight, views, and spatial functionality, it might not always be possible to separate noise-sensitive areas like living rooms and bedrooms. In such cases, secondary design solutions must be sought.

Designing Buffer Spaces Between Elevator Areas and Residential Zones

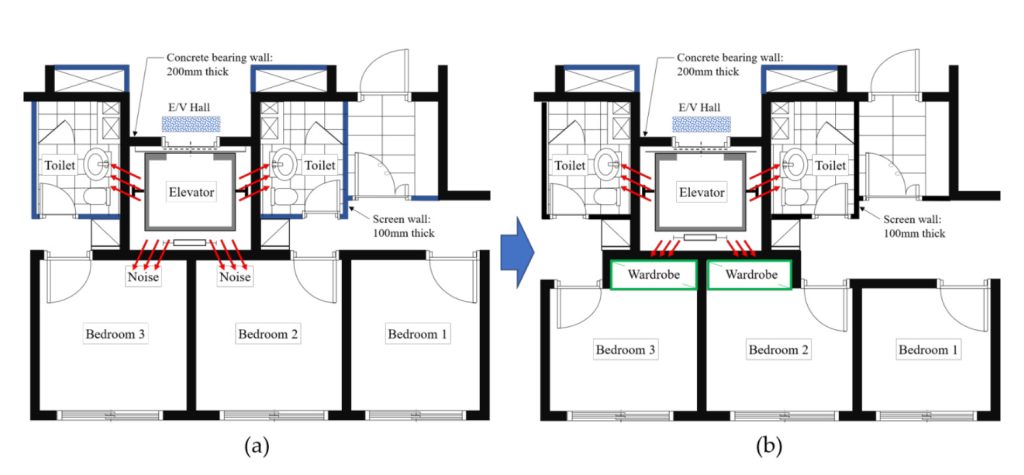

In high-rise apartment buildings, noise and vibrations from elevators significantly impact residents’ lives. The image below illustrates how an elevator operating close to a bedroom wall leads to direct transmission of noise and vibrations into the room. Bathrooms are less affected by this issue, whereas bedrooms can have their residents’ sleep and rest disturbed.

To mitigate the impact of noise and vibrations, the elevator’s load-bearing wall is designed with a thickness of 200 mm to obstruct airborne noise transmission. However, the effectiveness in blocking noise transmitted through the load-bearing material itself is limited. Therefore, to reduce noise transmission through the load-bearing material, a wardrobe can be placed as shown in Figure b. To assess the effectiveness of this approach, noise measurements in a bedroom with a wardrobe sharing a wall with the elevator were compared to those in a bedroom without a wardrobe under the same conditions.

Results indicate that installing a wardrobe can reduce noise levels by up to approximately 7.6 dB, despite the bedroom in Figure b having a different shape compared to the conventional rectangular bedroom in Figure a. This noise reduction is primarily achieved by using sound-absorbing materials such as blankets and clothing to dampen the noise or by implementing soundproofing measures to prevent noise transmission through the materials. Additionally, installing a wardrobe helps control the occurrence of sound waves in the low-frequency range.

Modifying Elevator Shaft Details

Elevators operating at a speed of 120 meters per minute are typically installed in high-rise buildings with 26 floors or more. In buildings with over 40 floors, elevators will operate at speeds of 180 meters per minute. High-speed elevators often cause air turbulence, leading to air friction and generating various types of noise. To reduce noise and vibrations from high-speed elevators in tall buildings, the following design solutions are necessary:

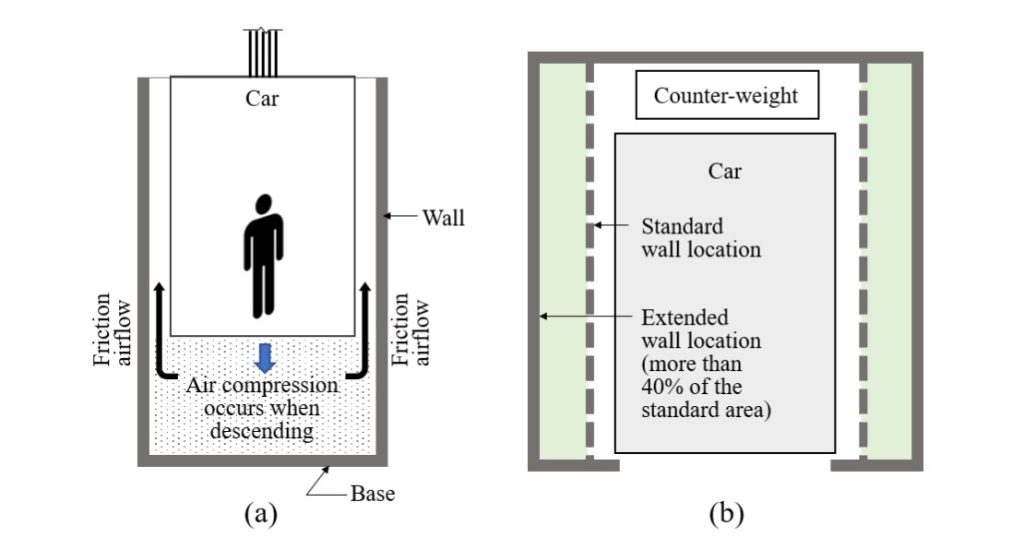

(1) Air Friction Noise

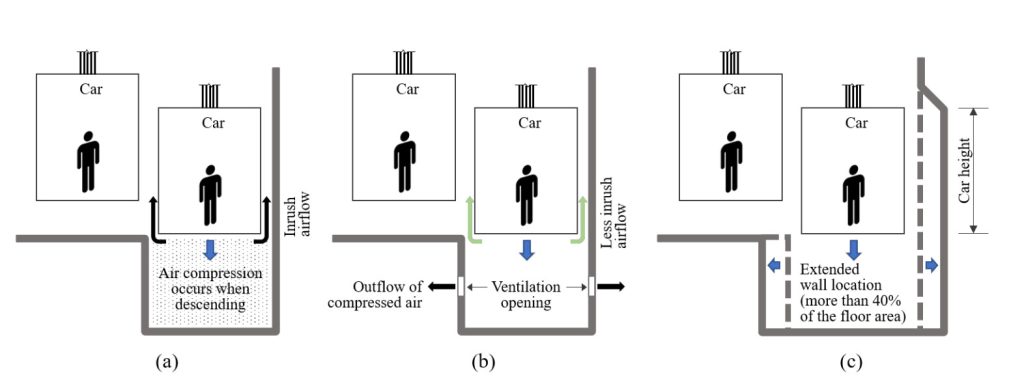

When an elevator moves at high speed in the elevator shaft (Figure 2a), air is compressed towards the machine room, creating an elevator piston effect that increases air pressure. The compressed air moves through the narrow gap between the machine room and the elevator shaft, producing noise known as air friction noise.

Air friction noise becomes louder when the narrow gap area is smaller compared to the machine room area, especially at higher elevator speeds. When two elevators operate simultaneously and in the same direction, the noise intensifies. However, with a speed of 120 meters per minute for one elevator and 180 meters per minute for two elevators, no significant issues occur. It is crucial that the elevator shaft area is designed to be approximately 40% larger than usual at high speeds, as shown in Figure 2b.

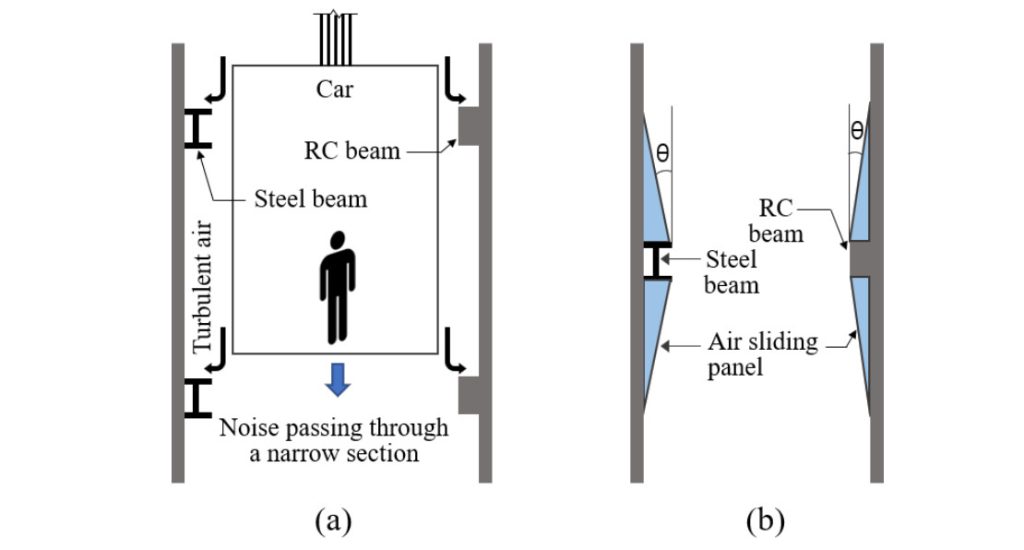

(2) Noise Passing Through Narrow Sections

Noise passing through narrow sections, also known as “puff noise,” is created when an elevator passes by protruding parts inside the elevator shaft (due to structural mechanisms or elevator guide components) as shown in Figure 3a. This causes an increase in air pressure and consequently more noise. In high-rise buildings, these protruding parts are designed floor by floor, resulting in repetitive noise generation across floors.

To mitigate this noise, the internal components of the elevator shaft should be designed without protrusions. If protrusions are unavoidable, an air deflector plate can be installed to reduce wind pressure and the resulting noise. The air deflector plate should have an inclination angle of 4-8°. This solution is particularly effective for high-speed elevators.

(3) Compressed Airflow Noise

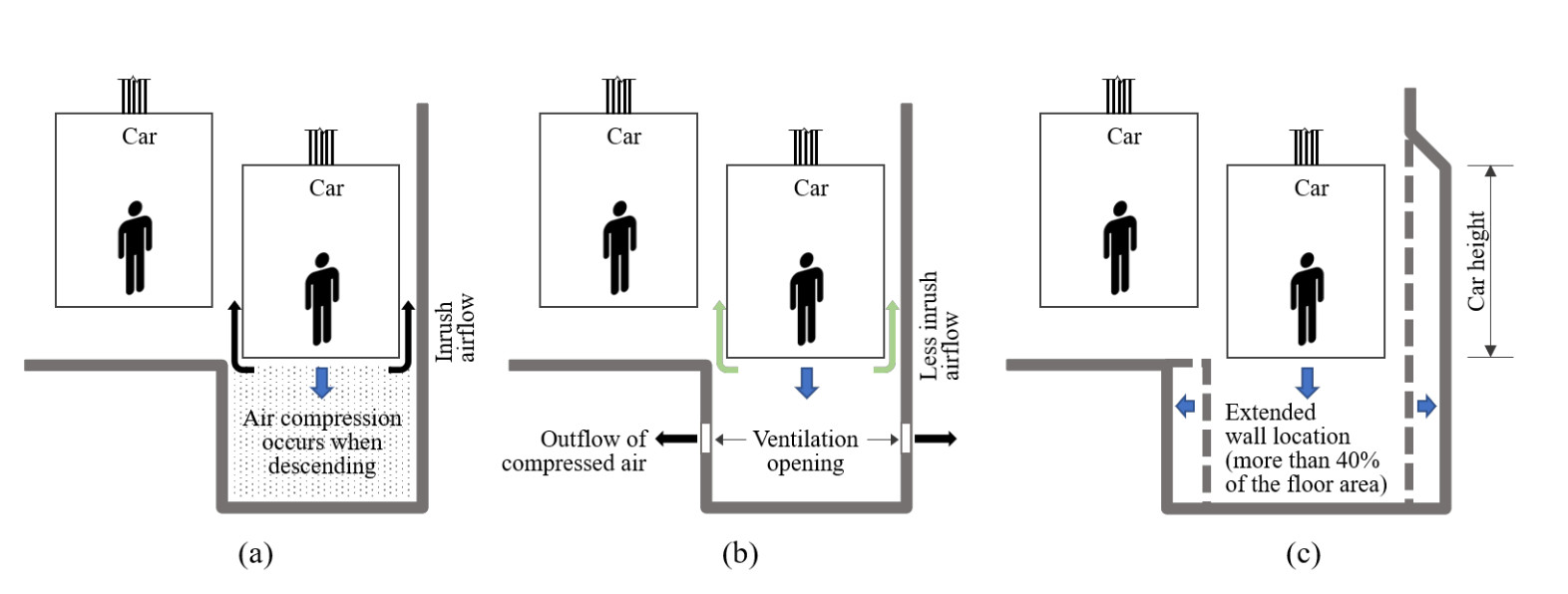

When more than two elevators are installed in high-rise buildings with over 20 floors and four apartments per floor, multiple elevators often share the same shaft (Figure 4a), leading to compressed airflow noise known as inrush noise. This noise frequently occurs when an elevator operates at high speed. Inrush noise is generated due to the rapid compression of air as the elevator enters the shaft.

The best solution to this problem is to avoid single elevator shafts; however, if structural limitations make this unavoidable, two solutions can be considered.

First, as illustrated in Figure 4b, ventilation openings can be placed on one or both sides of the elevator shaft wall. The size of the ventilation openings varies depending on the elevator’s size and speed; however, a design of around 1.5 square meters should not pose difficulties. If ventilation openings are challenging to implement, the elevator shaft walls can be extended so that the shaft’s floor area is increased by more than 40%.

(4) Pressure Differential Noise

High-rise elevators typically create a pressure difference between the waiting area and the elevator. Consequently, air flows in and out of the elevator through the gaps around the waiting area doors, generating noise known as pressure differential noise.

This noise worsens particularly when warm air from the heating system circulates within the elevator during winter and when the elevator ascends.

The solution to this problem is to design a double-layer entrance door or a revolving door to prevent cold outside air from entering the high-rise building. Additionally, incorporating air-blocking details around the elevator door frame at the waiting area, including the waiting area door, grooves, and elevator support walls, is recommended.

Noise Reduction Solutions Supporting Elevator Design

Read more: Giải pháp chống rung chống ồn cho thang máy

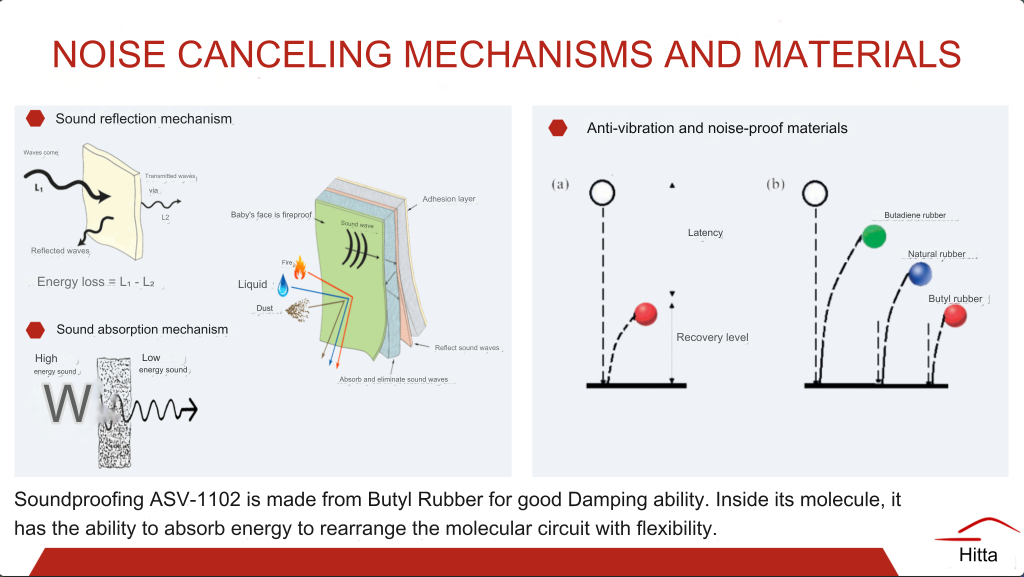

When noise reduction design solutions for elevators are not feasible, or when applied solutions still result in noise, using specialized soundproofing materials becomes essential.

As discussed in the article “Frequency Range of Noise & Vibration in Elevators,” the nature of noise involves frequency, necessitating the resolution of both low and high-frequency noise ranges. Noise reduction design solutions for elevators limit noise generation, but any remaining noise must be absorbed by specialized soundproofing materials.

This is where the ASV soundproofing material by Hitta maximizes its unique advantages, thanks to the material’s properties, which include:

- Impact absorption / Vibration absorption.

- Significant damping.

- Mitigation of vibrations from other components into the elevator cabin.

- Excellent resistance to wear and aging.

- Filling gaps to prevent surfaces from contacting each other, which causes vibrations.

- Adherence to uneven surfaces.

- Soft, flexible, and extremely easy to apply.

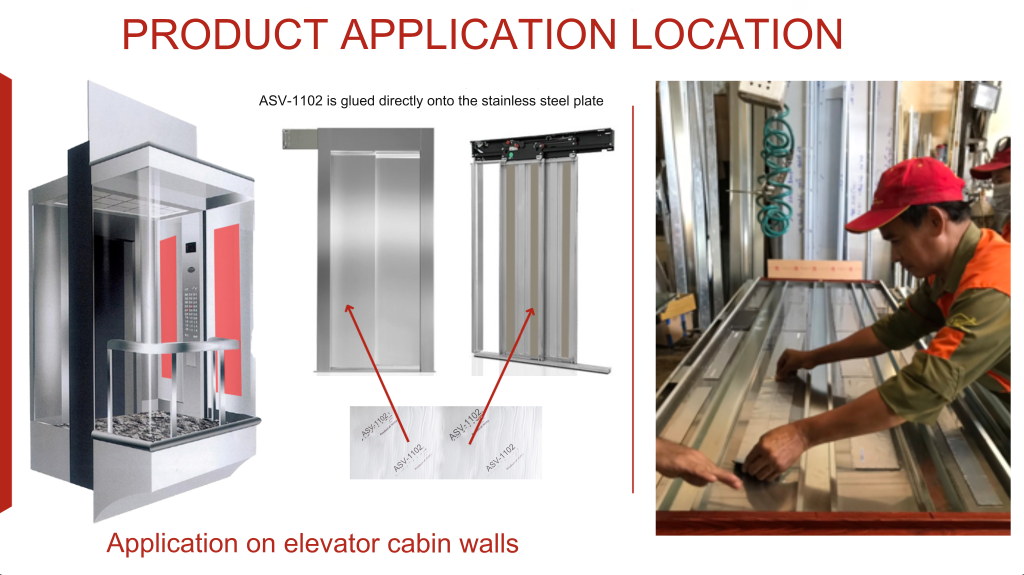

The ASV-1102 damping tape is a self-adhesive modified butyl rubber material. It adheres well to various surfaces and functions to absorb and dampen vibrations and noise across high, medium, and low frequency ranges. This makes it especially suitable for soundproofing and noise reduction in elevators, particularly in high-rise residential buildings.

The ASV-1102 damping tape suppresses sound and vibrations through its adhesive capability and special polymer matrix. It absorbs sound energy and vibrations due to its porous structure.

Related articles:

Contact Information

Hitta JSC is a leading provider of noise and vibration reduction products and solutions in Vietnam. Known for our Hitta brand products, we have successfully implemented solutions for elevators and high-end buses, coaches, and limousines, among others. Hundreds of units nationwide rely on Hitta’s noise and vibration reduction products, and this number continues to grow. Contact us today for consultation:

- ☎️ Hotline: 090.8611.011

- ✉️ Email: hittajsc@hitta.vn