Every year, millions of cars are manufactured worldwide, and each new model requires its own tape solutions. Many OEM manufacturers, component suppliers, and support providers have been and are increasingly switching to high-strength tape due to its significant advantages over traditional bonding solutions.

Hitta’s high-strength tape solution helps speed up and streamline the automotive assembly and manufacturing process, making it more efficient and, especially, optimizing costs for businesses.

- Băng keo cường lực dán kính ô tô

- Băng keo cường lực cho ngành công nghiệp ô tô

- Băng keo cường lực BowTape

- Băng keo cường lực cho dây chuyền sản xuất ô tô

- Tư vấn dán kim loại với kim loại trong ngành lắp ráp

- Băng keo cường lực dán kính ô tô

- Tăng tốc độ lắp ráp ô tô với băng keo siêu dính

Products:

Applications of high-strength tape in automotive assembly

Bonding and joining

High-strength tape provides strong, lightweight, permanent bonding and consistent use in automotive assembly processes. Applications include assembling heated seats, interior mirrors, infotainment systems, and attaching components and parts.

Vehicle interior

High-strength tape can easily be die-cut precisely to attach interior decorations throughout the vehicle using PSA adhesive applications. Applications include installing headliners, carpets, door frames, dashboards, and general surface decorations.

Vehicle exterior

There are many types of high-strength double-sided tapes available for durable and long-lasting bonding of components to the exterior of vehicles. The outstanding advantage of high-strength tape is its ability to precisely die-cut components, improving assembly efficiency and saving costs.

Applications include attaching emblems and logos, wheel arches, rear spoilers, and parking sensor mounting.

Exterior mirror installation

Specialized high-strength tape for automotive glass bonding provides strong, long-lasting, reliable adhesion, operating in all weather conditions and with very lightweight. The outstanding advantage of high-strength tape lies in reducing assembly time. Read the following article to learn more:

Sealing

High-strength tape is used to seal against dust, moisture, water, and other factors. Each product will be suitable for different automotive specifications. Applications include sealing lamp gaskets, air duct gaskets, speaker gaskets, and door seals.

Heat control

High-strength tape helps transfer heat superiorly from components to heat sinks. Foam-backed tapes are designed to improve surface contact and replace the use of heat-resistant grease.

Applications include electronic component clusters, heat-generating components, cooling fans to heat sinks, and heat dissipation components.

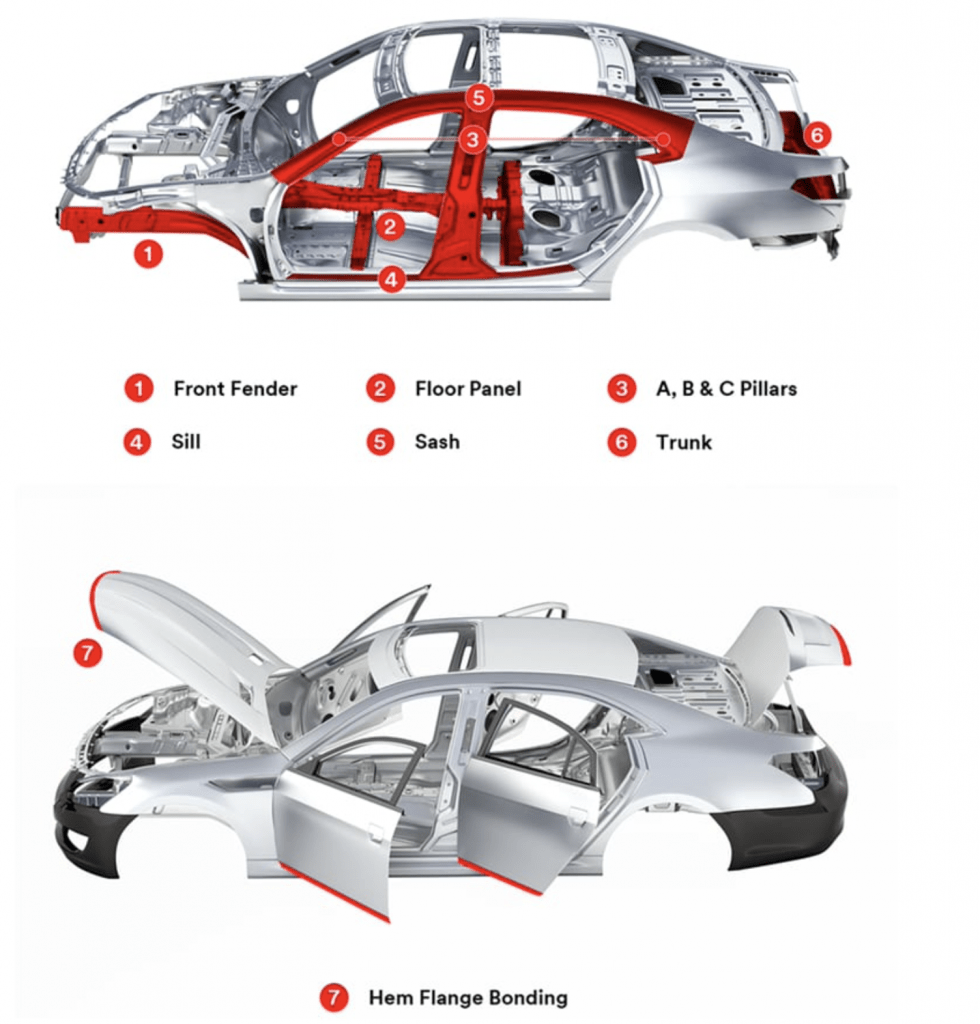

Body structure bonding before painting

High-strength tape is capable of bonding high-strength steel, aluminum, magnesium, and composite materials in the automotive body structure manufacturing process before painting (also known as BIW or body in white).

Applications include BIW structures, multi-material bonding, chassis frames, body support brackets, flange edges, and door panels.

High-strength tape is designed to help automotive OEMs enhance or even replace welds, screws, bolts, and other mechanical fasteners used in BIW applications. They enhance multi-material bonding – aluminum, structural steel, and some lightweight composite materials, suitable for bonding main structures and suspension parts such as doors, tailgates, and hoods. High-strength tape can be maintained at room temperature, helping OEMs reduce energy and emissions during BIW assembly. By increasing stiffness and creating conditions for stronger bonds, it helps reduce noise, vibration, and increase durability.

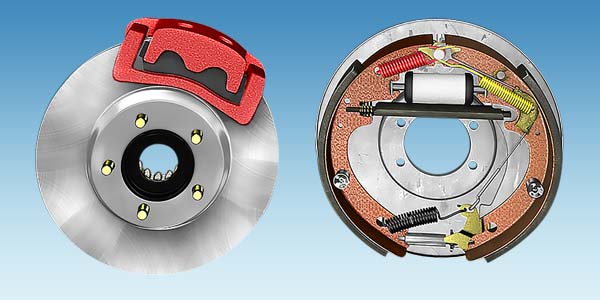

Wheel components

Main applications include dynamic balancing and brake pad shims.

Cable management

High-strength tape remains durable throughout the vehicle’s lifecycle and meets OEM quality standards. Applications include cable and wire mounting.

Why choose high-strength tape?

The outstanding advantages of high-strength tape:

- Load is distributed over a wider surface area. This helps eliminate stress concentration and minimize differences in material properties, such as mismatch in modulus of elasticity and thermal expansion coefficient.

- The adhesive and foam are highly flexible, thus able to rebound from light mechanical impacts, reinforcing the assembly of brittle components.

- The flexibility of the foam allows the tape to conform to the contours and shapes of the vehicle body, providing complete adhesion and better load distribution.

- High-strength tape has no residual stress like screws or welding, which is crucial when bonding long decorative parts, where screws can cause warping or deformation depending on the thermal expansion coefficient.

- Bond strength increases after initial assembly, reaching maximum strength after 72 hours as additional adhesive bonds form.

- Fast installation time due to simple application process, minimizing errors by installers and no waiting time for bonding (drying time like glue).

- High-strength tape is the most cost-effective bonding solution.

- Application benefits of high-strength tape:

- Vibration and noise reduction.

- Good sealing and insulation.

- Non-conductive joints, crucial when bonding different metals and alloys.

- Reduces or eliminates rattling noise from mechanical screws.

- Clean, neat, and aesthetically pleasing appearance.

- Improves manufacturing throughput.

- Enables new designs.

- No excess parts, minimizing additional frictional force

Application benefits of high-strength tape:

- Vibration and noise reduction.

- Good sealing and insulation.

- Non-conductive joints, crucial when bonding different metals and alloys.

- Reduces or eliminates rattling noise from mechanical screws.

- Clean, neat, and aesthetically pleasing appearance.

- Improves manufacturing throughput.

- Enables new designs.

- No excess parts, minimizing additional frictional force.

The durability of Bowtape industrial strength tape

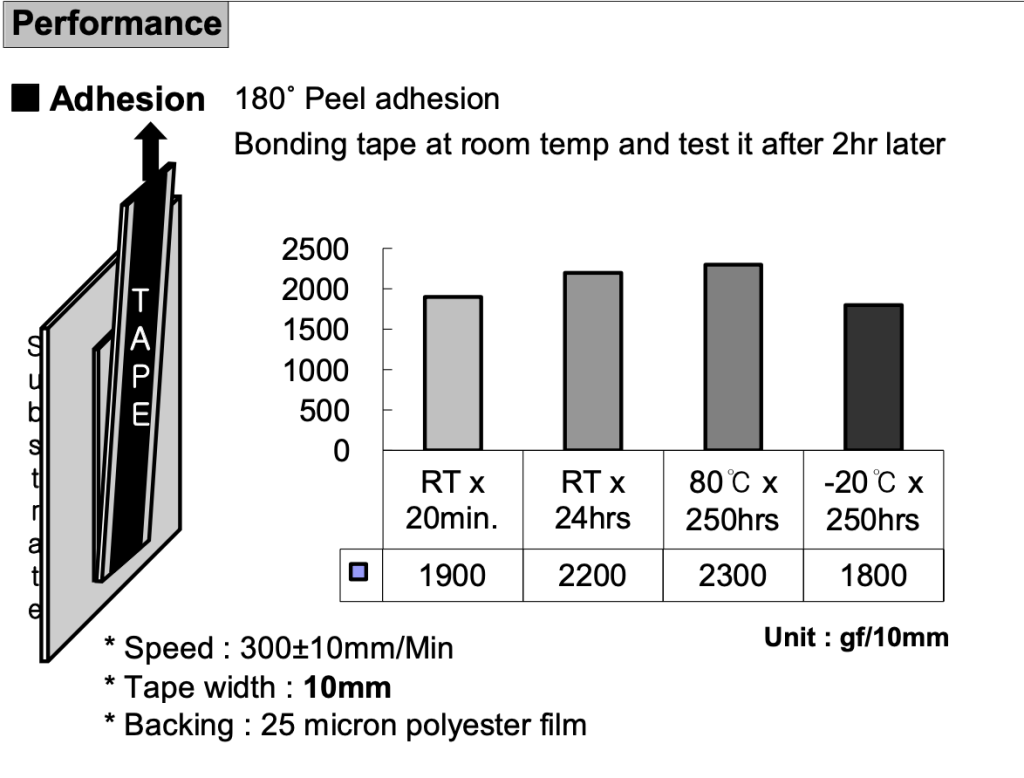

Adhesion strength testing

The test is as described in the figure:

- The peel angle is 180 degrees.

- The industrial strength tape is pulled for over 2 hours at room temperature.

- Result: good adhesion, minimal displacement, passing the test.

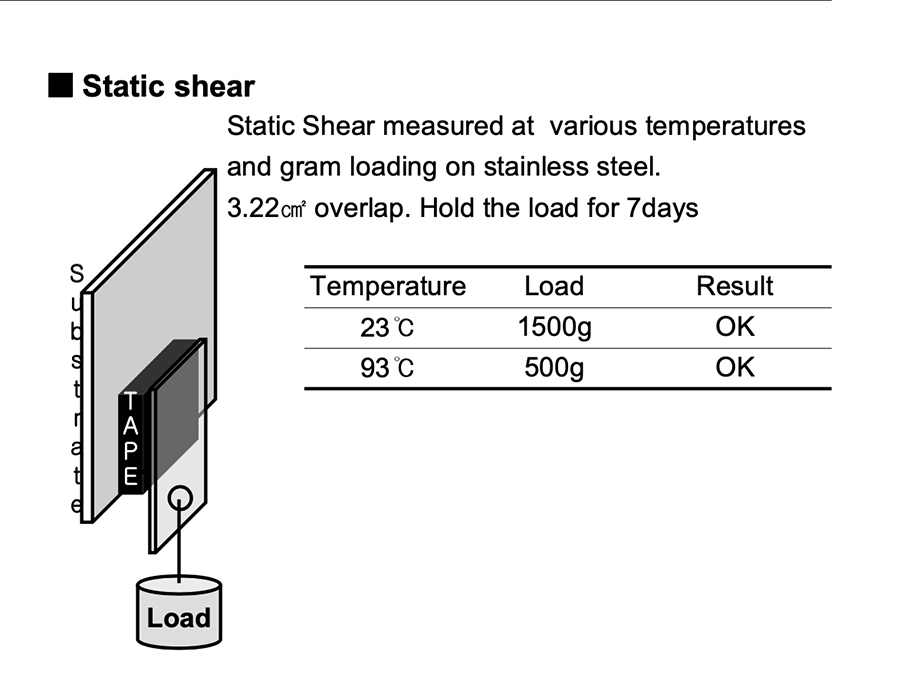

Gravity load testing

The test is as described in the figure:

- Enduring load for 7 days at different temperatures.

- Load 1: 1500g at 23°C.

- Load 2: 500g at 93°C.

- Result: good adhesion, passing the test.

Tensile strength test in both directions

The test is as described in the figure:

- Enduring tension from both sides (top and bottom) at room temperature for over 2 hours.

- Result: good adhesion, minimal displacement, passing the test

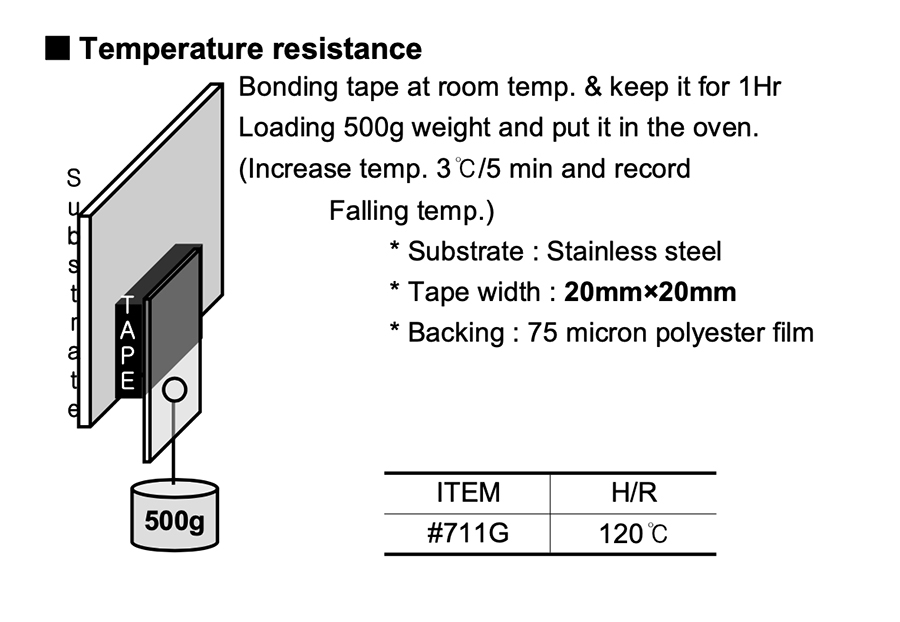

Temperature increasing durability test

The test is as described in the figure:

- Enduring a load of 500g at room temperature for one hour & gradually increasing the temperature.

- Every 5 minutes, the temperature increases by 3°C.

- Result: good adhesion, minimal displacement, passing the test.

Guidelines for using high-strength tape:

- The bonding surface must be smooth and clean for optimal bond strength.

- The tape curvature should match and snugly fit the surface.

- Apply the high-strength tape as close to the edge as possible to prevent water ingress behind the component.

- Start applying the tape from one corner to avoid bubbles or wrinkles that reduce effective contact area.

- On some difficult-to-adhere surfaces, primer may be used or high-strength tape with built-in primer

- Tại sao nên sử dụng băng keo cường lực?

- Tại sao nên sử dụng băng keo cường lực BowTape?

- Giải pháp băng keo cường lực

Contact Information

As the exclusive official distributor of BowTape high-strength tape in the Vietnamese market, Hitta JSC has the capability, expertise, and knowledge about BowTape products and solutions that the company distributes, providing more value and maximizing profits for Hitta JSC’s partners and customers.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn