Advanced adhesive tape solutions are designed to optimize production and reduce waste along the value chain until the final product.

Industrial tape solutions for the metal manufacturing and metal processing industries encompass most steps of the metal production process – from the core to the finished product, which typically serves as raw material for metal processing companies.

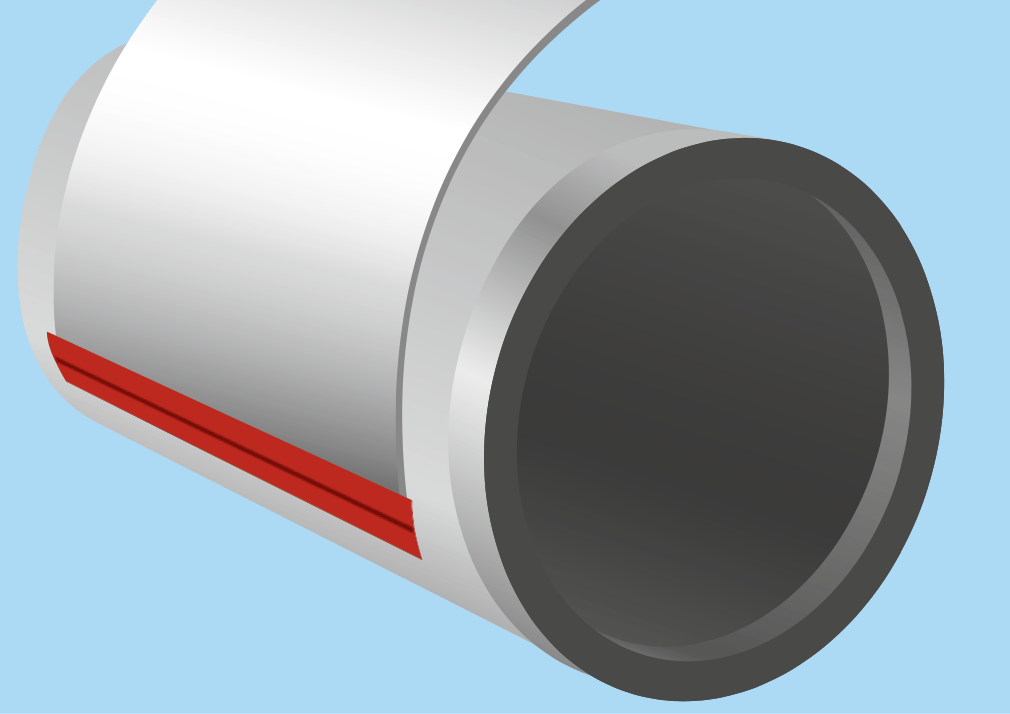

Attaching the beginning of the metal coil to the core

Transitioning from thick steel coils to thinner coils involves several core starting activities. Depending on the thickness and adhesion force of different steel layers, single-sided or double-sided tapes can be used to firmly attach the initial product layer to the core.

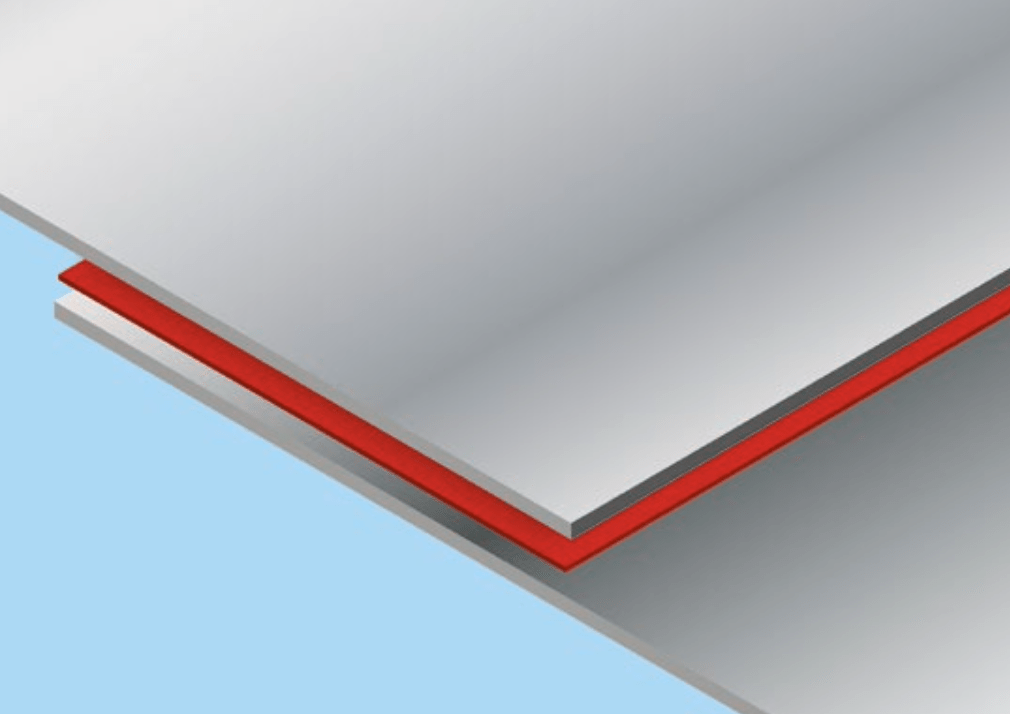

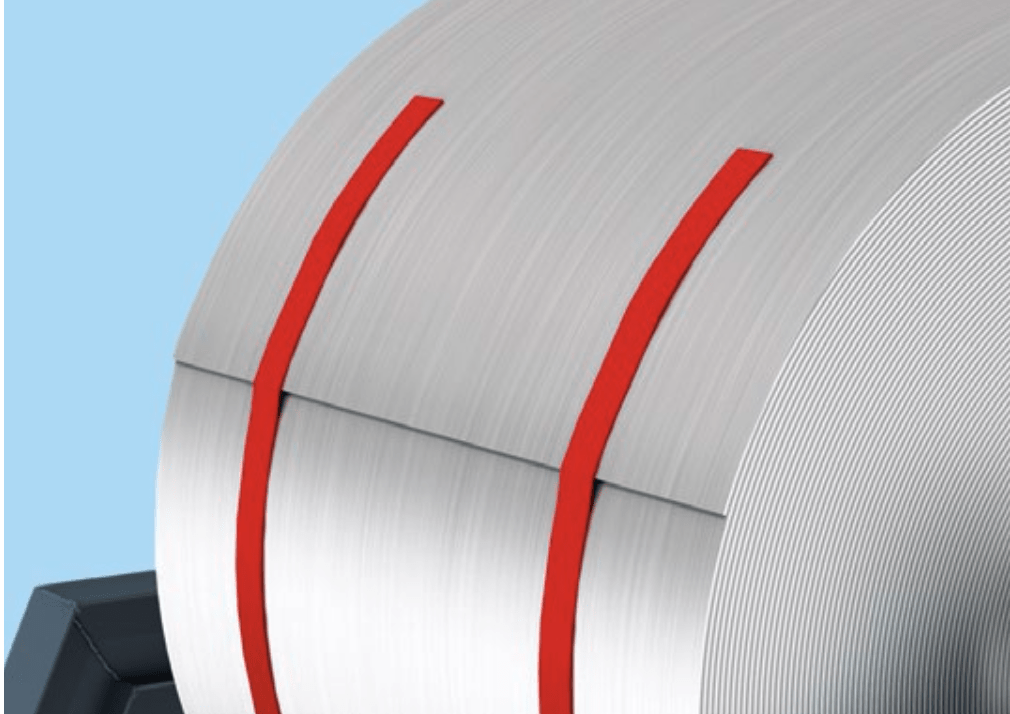

Stacking Metal Coils

Metal coils are stacked to run metal continuously through finishing and processing lines. The two most common coil joining techniques used are “end-to-end” and “butt joint.” For end-to-end stacking, Hitta provides double-sided tape solutions with adhesive compounds capable of withstanding high shear forces at high temperatures, as well as a backing layer to compensate for tensile stresses.

An additional benefit to enhance workplace safety is the use of double-sided tape for the edges of the metal coil.

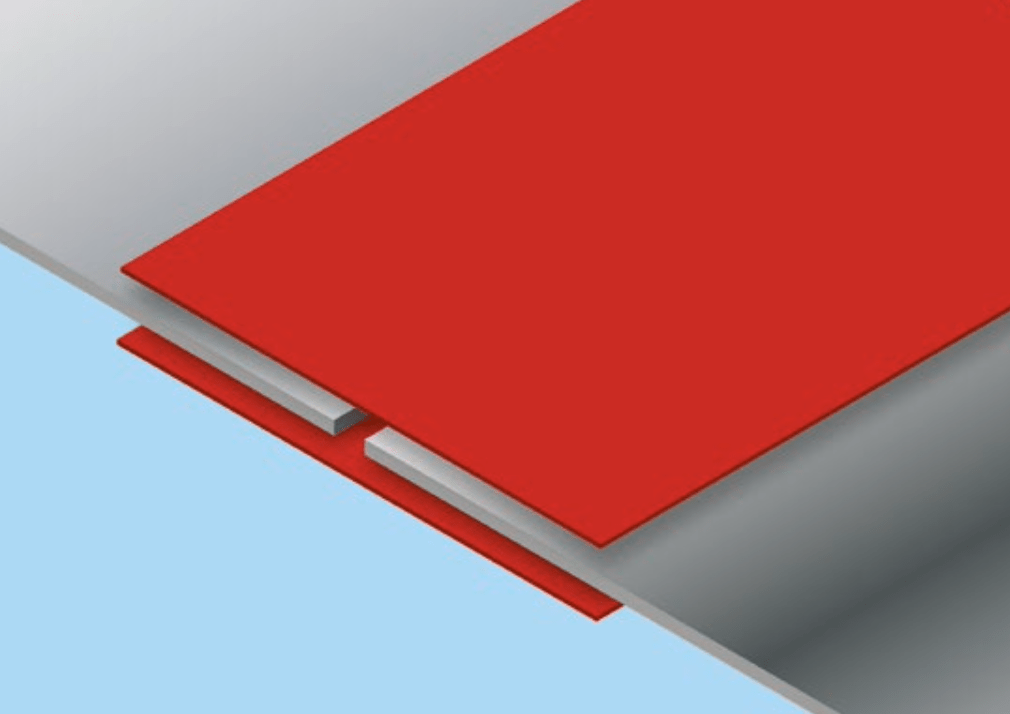

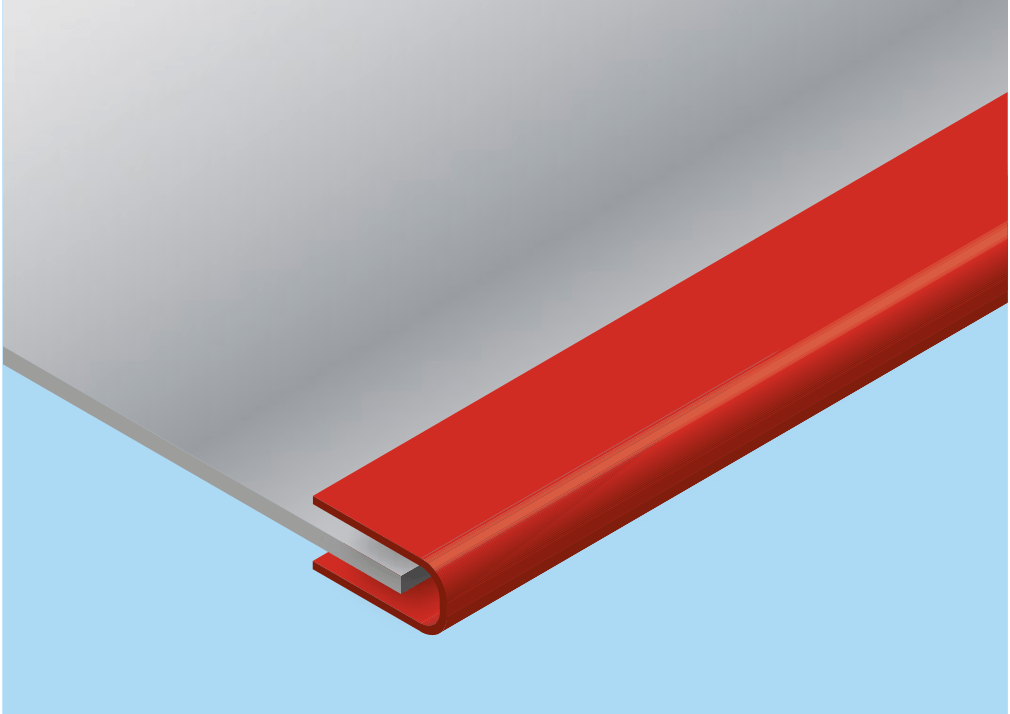

Joining the tail of metal coils

As outlined, in addition to end-to-end stacking, the second primary method is Joining the tail of metal coils. Here, extremely durable single-sided tapes with custom adhesive layers are used. A clear advantage is the reduction of material waste often associated with end-to-end joints.

For aluminum processors, this joining method also provides the opportunity to economically utilize short-length coils by analyzing the sequence of the coil beforehand.

Attaching the end of metal coils

Metal wire coils are sealed at the end for transportation inside and outside the factory. Securing the metal coils tightly with industrial tape helps prevent them from unwinding during transportation. Industrial tape is stretchable, with very high tensile strength, especially tear-resistant.

Thanks to the tape, the metal coils are reinforced for safety, ensuring the safety of employees.

Applying edge and surface protection to metal

Further along the metal processing value chain, for companies with various specialties processing aluminum and steel products. In this manufacturing process, protecting edges and surfaces is also necessary to safeguard workers from personal injuries and to protect semi-finished and finished products from damage such as scratches, dirt during transportation inside and outside.

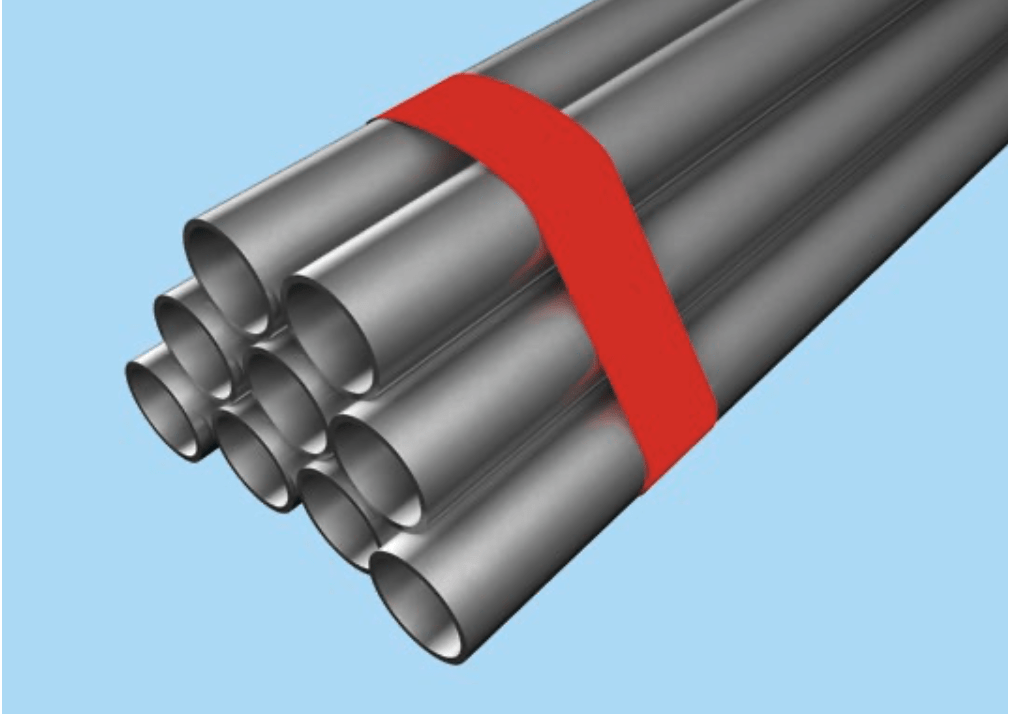

Bundling & marking finished products

Industrial tape helps reinforce products. With safety and reliability, it helps minimize the risk of damage to products while also protecting employees from injuries caused by individual packaged products loosening during transportation or during picking and packing activities in the warehouse. Additionally, tape can be used to mark products, with each color of tape indicating a different type of metal, facilitating quick inventory checks or picking items from the warehouse.

Contact us

Hitta specializes in providing industrial tape for various industries and commercial sectors. Contact us for the most efficient solutions at the lowest cost.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn

Các ứng dụng khác: