Industrial adhesive tape provides quick and easy solutions to enhance installation efficiency and minimize transition time.

Outstanding advantages of adhesive tape compared to traditional methods

Lighter: Hitta industrial adhesive tape offers up to 60% weight savings per square meter compared to traditional bonding methods. Weight savings per square meter have a significant impact on fuel savings, which is especially important for electric or hydro-powered vehicles.

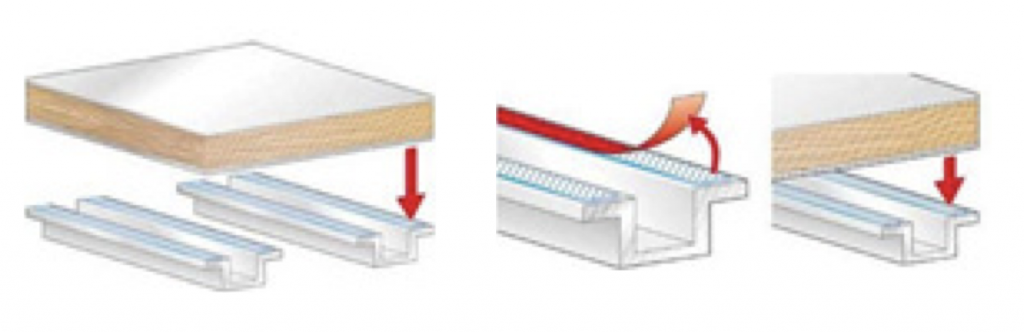

Faster: No need for trained labor. Acrylic PSA adhesive provides instant adhesion, eliminating waiting time for curing. The installation process involves simple 3-step procedures: Peel, Position, Stick.

Safer working environment: No solvent required, completely eliminating harmful substances to the environment and the health of installers. Tape deployment does not require complex, bulky, or hazardous equipment or tools (such as welding).

With the increasing trend of extending the overhaul and maintenance intervals for buses, the long-term durability of components and assemblies is becoming increasingly important. Industrial adhesive tape can help improve overall durability. For example, unlike mechanical screws, rivets, or spot welding where mechanical stress is concentrated at a specific point, structural adhesive tape evenly distributes stress across the entire substrate surface. Non-conductive adhesive tape therefore prevents electrochemical corrosion between different metals and is capable of withstanding high loads.

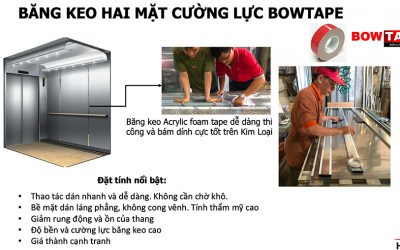

- Outstanding advantages of adhesive tape for bus flooring:

- Applicable in areas with high passenger traffic density.

- Good vibration resistance.

- Good sound insulation.

- Can adhere to various types of substrates.

- UV resistant.

- Chemical resistant.

- Resistant to high humidity.

- Resistant to high temperatures (some types are flame retardant).

The overall cost reduction when using adhesive tape includes:

- Saving labor and training costs.

- Time savings.

- Reducing process steps.

- Less material usage.

- Minimizing some safety control measures.

- Optimized workflow.

- Lighter weight.

- Easier removal.

Choosing the appropriate adhesive tape for different substrates

Floor panels and floor coverings come in various substrate types, often made from vinyl, polyolefin, rubber, or polyamide. Key factors influencing the choice of flooring can be aesthetics, durability, flexibility, weight, slip resistance, moisture absorption, comfort, soundproofing, fire/smoke/toxicity resistance, ease of installation, and cleanliness.

The increasing shift towards more sustainable solutions may lead to a higher proportion of natural or recyclable substrates. Floor coverings can be applied onsite or provided in the form of self-adhesive roll tapes.

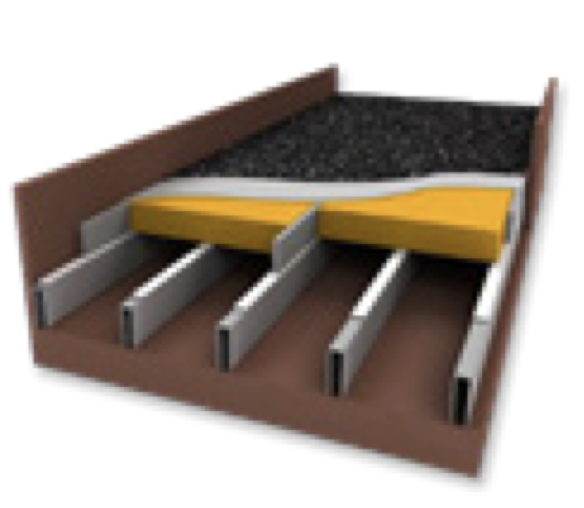

Floor coverings can be applied to composite floors, aluminum floor panels, laminated floor coverings, or subfloors made of plywood.

Plywood remains the most commonly used material for bus flooring, but bus manufacturers are increasingly interested in lightweight and moisture-resistant alternatives, such as panels made from synthetic materials with foam cores, honeycomb aluminum panels, or even aluminum sheets.

Surface Preparation

Surface preparation is an important part of the process; dust, oil, and dirt must be removed from the surface to be bonded using solvents or some cleaning chemicals. Some metals may require removal of oxidized layers on the surface.

Uneven surfaces can be treated by using adhesives with good gap-filling properties. Adhesive tape can provide a consistent bond line.

Combining Solutions

The bus chassis can be bonded using adhesive and tape solutions:

- Industrial adhesive tape helps bond the chassis instantly with minimal thickness.

- Industrial sealant adhesive is used to fill gaps when necessary.

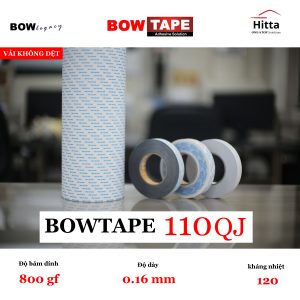

Choosing the appropriate high-strength adhesive tape

Here’s the information presented as a data table:

| Feature | Thin Acrylic Tape (0.05–0.13mm) | Thick Acrylic Tape (>0.6mm) |

|---|---|---|

| Main Value | Solid 100%, can be applied manually, repositionable initially, safe & low toxicity | Self-adhesive, gap-filling, quick application, insulation |

| Handling | Very easy, may require smooth surface finish for flooring applications | Very easy |

| Performance | Moderately good resistance | Strong bonding, viscous elasticity, good water sealing |

| Aesthetics | Moderate aesthetic finish | Good aesthetics, no visible cracks due to tight floor seams |

| Maintenance | Easy removal | Can be removed with chemicals |

Contact Us

Hitta specializes in providing specialized adhesives and tapes for both industrial and commercial sectors. Contact us for advice on the most efficient solutions at the lowest cost.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn