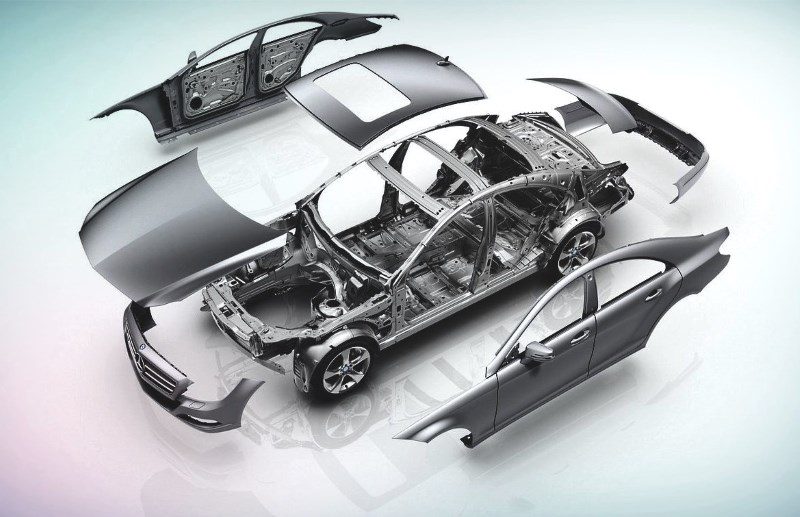

The advancement of bonding technology allows for increasingly intelligent solutions in vehicle body assembly and repair, replacing conventional mechanical methods and bringing numerous benefits.

Hitta’s industrial adhesive solutions meet the strict requirements of the industry and specific assembly lines of customers.

Faster body assembly process

The value of industrial adhesives for the body assembly process:

Improved methods: a significant issue in bus body assembly lies in bonding long side panels, requiring stringent tensile strength. Industrial adhesive solutions can address this issue.

Lightweight: mechanical welds and screws will be replaced by adhesives significantly reducing the vehicle’s weight, leading to reduced fuel consumption and emissions. In buses, the use of industrial adhesives can reduce weight by up to 80 kg.

Corrosion resistance: welds and screws tend to rust over time. Adhesive solutions for body bonding are corrosion-resistant. In some cases, adhesives can even prevent corrosion and act as a barrier between metal panels.

Noise and vibration reduction: automotive body adhesive effectively eliminates vibration and noise caused by engine and motion propagation. Unlike mechanical methods prone to loosening and adding noise or breaking, weakening connections. This is particularly beneficial for public transportation vehicles like buses.

Bonding different materials: automotive panel adhesive is most commonly used as the use of composite materials increases. Additionally, other vehicles benefit from the ability to bond metal to composite materials.

Cost-effectiveness: cost and time efficiency are closely related to body adhesive. For vehicle assembly, body adhesive is cheaper than traditional methods and related to the application process. Applying body adhesive to large side panels can be fully automated, saving time and money.

Easier vehicle body repairs

Quick repairs: Adhesives can be applied faster than mechanical screws and do not require training like welding methods.

Repairing hard-to-reach areas: Some complex positions cannot use welding or traditional mechanical methods (these methods often damage material surfaces). Adhesives can be deployed anywhere in the vehicle without affecting the material surface.

Repairing between different materials: Another reason why welding is not an option is that this method cannot bond different materials. In vehicle manufacturing, more and more composite materials are being used, meaning that repairing these materials is becoming more common. Industrial adhesives are an option for any material.

Industrial adhesive solutions

Depending on the process and stage, specialized adhesives for vehicle body assembly will vary:

- Hot melt adhesive.

- Water-based adhesive.

- Solvent-based adhesive.

- Methyl methacrylate (MMA) adhesive.

- Polyurethane adhesive.

- Silicone adhesive.

- MS polymer adhesive.

Hitta specializes in providing specialized adhesives and tapes for both industrial and commercial sectors. Contact us for advice on the most efficient solutions at the lowest cost:

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn

Tham khảo sản phẩm:

-

Adhesive for aluminum door corners, aluminum frame windows, aluminum flash doors | Bostik Aluseal

Adhesive for aluminum door corners, aluminum frame windows, aluminum flash doors | Bostik Aluseal -

Bostik N310 Multi-Purpose Construction Adhesive

Bostik N310 Multi-Purpose Construction Adhesive -

Bostik H505 – transparent sealant & adhesive

Bostik H505 – transparent sealant & adhesive -

Bostik P310 – expanding foam adhesive for thermal insulation and sound reduction

Bostik P310 – expanding foam adhesive for thermal insulation and sound reduction -

Bostik H725 hybrid adhesive designed for facade cladding and expansion joints

Bostik H725 hybrid adhesive designed for facade cladding and expansion joints -

Bostik S736 Premium, Neutral Grade, High Modulus Silicone for Glazing & Facade Applications

Bostik S736 Premium, Neutral Grade, High Modulus Silicone for Glazing & Facade Applications -

Bostik S551 – neutral silicone for gutters and roofs

Bostik S551 – neutral silicone for gutters and roofs -

Bostik P795 – sealant for filling large gaps

Bostik P795 – sealant for filling large gaps -

Bostik P590 – sealant for construction & expansion joints

Bostik P590 – sealant for construction & expansion joints -

Bostik A330 FILL A GAP FLEX

Bostik A330 FILL A GAP FLEX -

Bostik S546 Silicone – moisture resistance and waterproofing

Bostik S546 Silicone – moisture resistance and waterproofing -

Bostik H360 hybrid sealant for construction & glass façade

Bostik H360 hybrid sealant for construction & glass façade -

Bostik H785 – No more screws, Instant Adhesive

Bostik H785 – No more screws, Instant Adhesive -

Bostik 7575

Bostik 7575 -

Bostik S548

Bostik S548 -

Bostik 7003

Bostik 7003 -

Bostik 7008

Bostik 7008