Bostik’s adhesive solutions provided by Hitta are used in various industries, from industrial manufacturing, assembly, and transportation, to everyday mobility-enhancing applications.

Bostik in the Transport Sector

Bus and truck manufacturers demand adhesive technology capable of coping with the specific conditions of each region, such as high temperatures or exposure to ultraviolet rays.

For buses, coaches, and shuttles, Bostik has developed a range of specialized adhesive technologies for both interior and exterior applications, helping customers optimize processes and increase profitability, while ensuring safety, lightness, and durability.

- 50% of bus manufacturers are currently using Bostik’s technology.

- 70% of MS polymer in bus applications come from Bostik.

- 98% of bus-related issues can be addressed with Bostik’s technology

Accompanying the Customer

- Safer: Meeting and adhering to strict safety standards, ensuring the health of the workforce.

- Lighter: Bus manufacturers are redesigning their products and seeking any opportunities to integrate lighter materials without compromising performance and added value.

- Sustainable: Bus manufacturers must comply with increasingly stringent environmental regulations, requiring responsible manufacturing processes and product lifecycle research.

Interior applications

Bostik provides solutions for a variety of interior applications, including

- Seating.

- Flooring & roofing.

- Cockpit & components.

- Glass.

Depending on the application, Bostik recommends solutions based on different technologies:

- Sealants.

- Structural adhesives.

- Water-based adhesives.

- Hot melt adhesives.

Key requirements include:

- Ease of use.

- Low VOC (Volatile Organic Compound).

- Solvent-free.

- Lightweight.

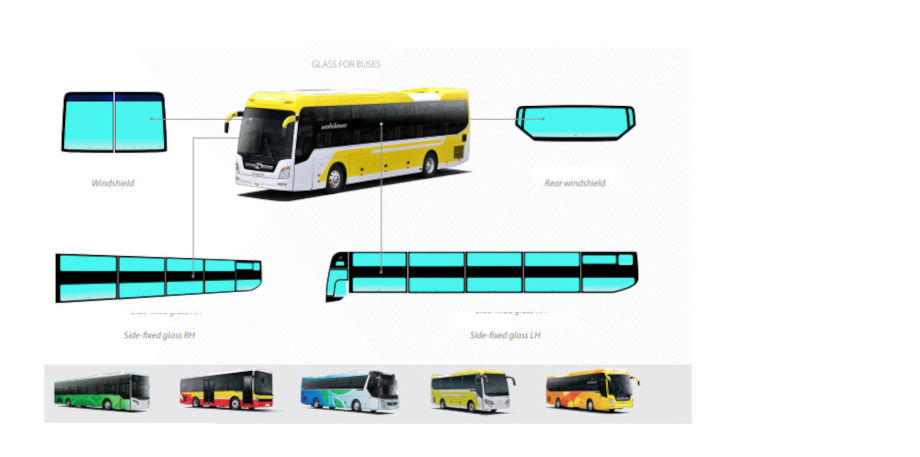

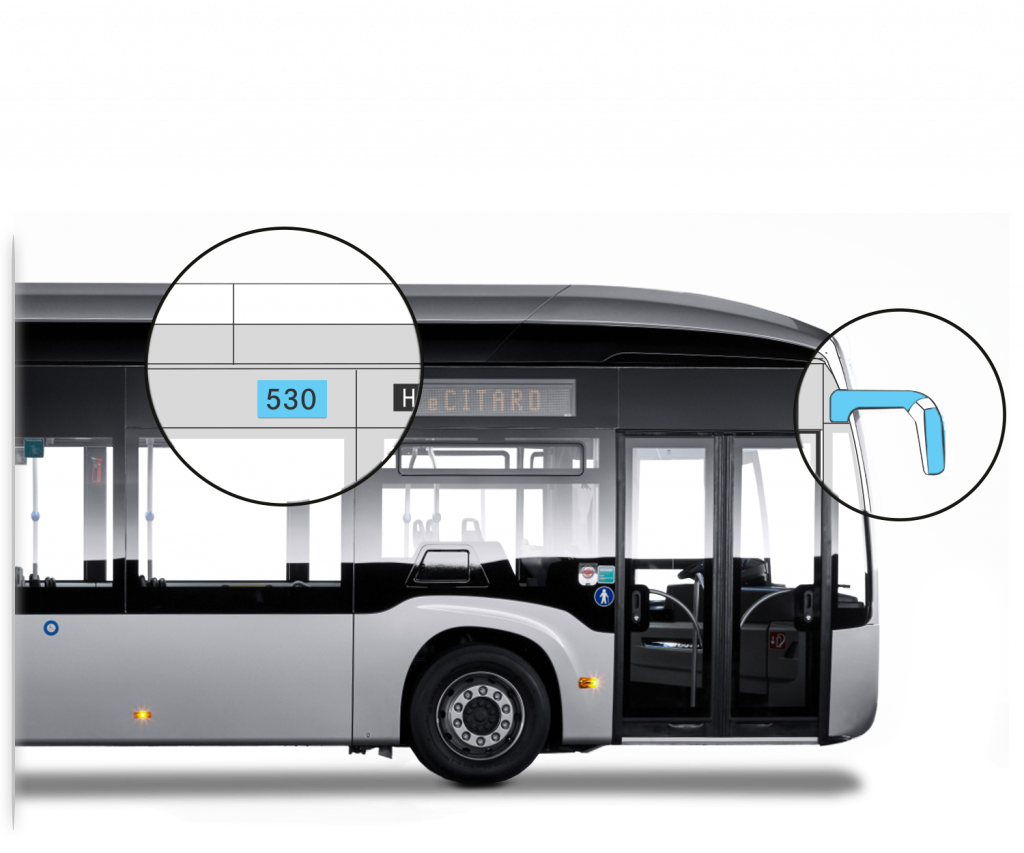

Exterior applications

Bostik provides solutions for a variety of exterior applications, including:

- Bonding & sealing glass.

- Bonding side panels of buses.

- Bonding vehicle frames.

- Bonding exterior components.

Depending on the application, Bostik recommends solutions based on different technologies:

- Sealants.

- Structural adhesives.

- Hot melt adhesives.

Key requirements include:

- Ease of use.

- Low VOC (Volatile Organic Compound).

- Solvent-free.

- Lightweight.

Advice on Choosing the Right Adhesive

Sealants are designed to meet all bonding and sealing requirements while significantly reducing production time. Bostik has led the market in SMP (Silyl Modified Polymer) technology in the transportation industry for over 25 years. The UV resistance makes the sealant ideal for sealing windows and bus body structures. SMP products also save time in the painting process. Paint can be applied once the beads have formed, while polyurethane sealant needs to cure completely before painting.

Structural adhesives provide load-bearing capabilities, helping to increase strength for the final bonded assembly for durability. Bostik MMA (Methyl Methacrylate) provides a unique balance of high strength, impact resistance, flexibility, elongation, shear strength, and peel strength, and can be used over a wide temperature range. Bostik structural adhesives cure at ambient temperature with controlled curing rates and require little or no surface preparation. They are also moisture-insensitive and have excellent water and chemical resistance.

Hotmelt adhesives offer several advantages for a range of applications: optimal holding force for corrugated materials, superior flexibility for better performance under continuous pressure, and quick bonding. Bostik Butyls for exterior applications are non-hardening mastic sealants designed to form a weather-resistant and dust-proof adhesive that is highly flexible.

Liquid adhesives can be sprayed and provide excellent adhesion to low-energy surfaces. Solvent-based adhesives are designed for pressure-sensitive bonding with fast drying times, quick handling, and good resistance to sagging. Water-based bonding technology is an environmentally friendly product with high flexibility, fast evaporation but cannot bond to many substrates. The adhesive also has high adhesion and good water and heat resistance.

Selecting Adhesives for Interior Applications

| Vehicle Area | Sealant | Structural Adhesive | Liquid Adhesive | Hot Melt |

|---|---|---|---|---|

| Side Panels | Recommended | Feasible | Recommended | |

| Flooring | Recommended | Feasible | ||

| Floor Covering Panels | Recommended | Recommended | Recommended | |

| Driver’s Cabin | Feasible | Feasible | Recommended | |

| Rear Seat Components | Feasible | Recommended | ||

| Seats | Recommended | Recommended | Recommended | Recommended |

| Window Finishing | Recommended | Feasible | ||

| Window Sealing | Recommended | Feasible | ||

| Luggage Tray | Feasible | Recommended | Recommended | |

| Driver Area | Recommended | Recommended | ||

| Destination Display Panel | Recommended |

Selecting Adhesives for Exterior Applications

| Vehicle Area | Sealant | Structural Adhesive | Hot Melt (Hotmelt) | Butyl (Liquid or Tape) |

|---|---|---|---|---|

| Edge, Front & Rear | Recommended | Feasible | Feasible | |

| Windshield | Recommended | Feasible | ||

| Side Glass | Recommended | Feasible | Recommended | |

| Window Sealing | Recommended | |||

| Body Panels | Recommended | Feasible | Recommended | Recommended |

| Luggage Compartment Door | Recommended | Feasible | Recommended | |

| Door Panels & Windows | Recommended | Feasible | Recommended | |

| Emergency Exit | Recommended | Feasible | Recommended | |

| Roof | Recommended | Feasible | Feasible | |

| HVAC | Recommended | |||

| Chassis Frame | Recommended |

Bostik products:

-

Adhesive for aluminum door corners, aluminum frame windows, aluminum flash doors | Bostik Aluseal

Adhesive for aluminum door corners, aluminum frame windows, aluminum flash doors | Bostik Aluseal -

Bostik N310 Multi-Purpose Construction Adhesive

Bostik N310 Multi-Purpose Construction Adhesive -

Bostik H505 – transparent sealant & adhesive

Bostik H505 – transparent sealant & adhesive -

Bostik P310 – expanding foam adhesive for thermal insulation and sound reduction

Bostik P310 – expanding foam adhesive for thermal insulation and sound reduction -

Bostik H725 hybrid adhesive designed for facade cladding and expansion joints

Bostik H725 hybrid adhesive designed for facade cladding and expansion joints -

Bostik S736 Premium, Neutral Grade, High Modulus Silicone for Glazing & Facade Applications

Bostik S736 Premium, Neutral Grade, High Modulus Silicone for Glazing & Facade Applications -

Bostik S551 – neutral silicone for gutters and roofs

Bostik S551 – neutral silicone for gutters and roofs -

Bostik P795 – sealant for filling large gaps

Bostik P795 – sealant for filling large gaps -

Bostik P590 – sealant for construction & expansion joints

Bostik P590 – sealant for construction & expansion joints -

Bostik A330 FILL A GAP FLEX

Bostik A330 FILL A GAP FLEX -

Bostik S546 Silicone – moisture resistance and waterproofing

Bostik S546 Silicone – moisture resistance and waterproofing -

Bostik H360 hybrid sealant for construction & glass façade

Bostik H360 hybrid sealant for construction & glass façade -

Bostik H785 – No more screws, Instant Adhesive

Bostik H785 – No more screws, Instant Adhesive -

Bostik 7575

Bostik 7575 -

Bostik S548

Bostik S548 -

Bostik 7003

Bostik 7003 -

Bostik 7008

Bostik 7008

Contact information

Hitta specializes in providing specialized adhesives and tapes for both industrial and commercial sectors. Contact us for the most cost-effective and efficient solution advice.

- ☎️ Hotline: 090.8611.011 (Mr. Dương).

- ✉️ Email: hittajsc@hitta.vn